Source: zhe design doesn’t need to look at how many papers he has published or what awards he has won

.

It only needs to look through the list of main drafters of the calendar version of code for design of concrete structures to know Mr

.

Bai Shengxiang’s position in the field of concrete structures in China

.

Years ago, I had the honor to visit Mr

.

Bai under the leadership of Mr

.

Feng

.

He is nearly 90 years old and is still in good spirits

.

Instead of staying at home, he is sitting in the coffee shop on the first floor of the office building

.

In addition to climbing the relationship of Nanjing Institute of technology, recognizing the master and making up with each other, there was no more greetings and directly cut into the topic of concrete

.

As soon as Mr

.

Bai came up, he said that he had read the story I wrote last week about checking 0.85 during my school visit in the UK, and naturally brought the topic to 0.88 in the concrete code

.

Mr

.

Feng called it “mysterious 0.88”, which I deeply believe

.

I didn’t understand it when I was in class, and I didn’t believe in Mr

.

Ye’s explanation

.

Later, I became confused

.

Mr

.

Feng once assigned it to the students as an assignment

.

For details, please refer to the fifth collection of challenging assignments in the course of “concrete structure” – mysterious 0.88 by Qing Xiaohun and Qing Xiaofu

.

Curing conditions, long-term strength, size effect, loading rate Various explanations not only fail to reveal the secret, but highlight the mystery of this coefficient

.

According to Mr

.

Bai, this coefficient was formally introduced from the 89 code

.

At that time, the main benchmark was the United Kingdom, but the reference to the United States was relatively small

.

But both Britain and the United States have such a strength reduction factor, and the United Kingdom uses hognestad’s 0.85

.

In 1952, hognestad proposed the famous hognestad stress-strain curve (hognestad 1952, j.aci24 (2): 117-139)

.

It is an empirical coefficient based on a large number of experimental data of concrete columns under axial compression in 1930s

.

According to hognestad, it mainly reflects the influence of size and shape of members

.

So, why is the norm 0.88 instead of 0.85? Is it based on our own test results? Does the difference between the two reflect the difference between Chinese concrete and American concrete? Or does it reflect the difference between the cube strength FCU and the cylinder strength FC ‘? Stop guessing

.

According to Bai Lao, the reason why it is 0.88 is mainly to compare the reliability level of British concrete code

.

The greatest truths are the simplest! Originally, it was a highly engineering adjustment coefficient, but it had to be scientific

.

If the standard is further improved and the reliability level is changed to 0.85 or even 0.8 one day, won’t it have to be interpreted like a tiger again? When it comes to reliability, load and resistance factor design (LRFD) – partial factor method is indispensable

.

Our country is also from the beginning of the 89 code, from the old K to the partial coefficient method

.

The load factors are similar in different countries, while the resistance factors are divided into two groups

.

On the one hand, the component partial factor represented by the United States reduces the bearing capacity at the component level; on the other hand, the material partial factor represented by the United Kingdom further reduces the material strength standard value to the strength design value, and uses the strength design value to calculate the bearing capacity of the component

.

Our country belongs to the latter camp

.

Seriously, when I was in school, I was tortured by the design value, so I was dizzy

.

I didn’t like it all the time

.

What’s the physical meaning of using it to calculate the height of the compression zone, the relationship between bending moment and axial force and so on

.

When we put forward this question, Mr

.

Bai first gave the United States a thorough explanation

.

He said that you may not know that in fact, the former Soviet Union used the so-called “three coefficient method” for a long time, that is, homogenization coefficient, overload coefficient and working condition coefficient

.

Among them, the homogeneity factor is equivalent to the super strength factor of the material itself, the overload factor is equivalent to the partial load factor, and this working condition factor is equivalent to the member bearing capacity reduction factor pHi in the American code

.

So there’s no need to blindly believe in American practices

.

So what’s wrong with the partial coefficients? Taking the calculation of the bearing capacity of reinforced concrete normal section as an example

.

For the RC section with symmetrical reinforcement shown in the figure below, the M-N correlation curve obtained by using the standard value of material strength through section analysis is shown as the red solid line in the figure below

.

The M-N curve obtained by material strength design is black solid line

.

It can be seen that the safety reserve in the stage of small eccentric compression controlled by concrete compression is much larger than that in the stage of large eccentric compression controlled by steel tension, and the transition of the safety reserve is smooth and continuous

.

In other words, the influence of the so-called “working conditions” on the safety reserve of components can be automatically considered by using the design value of material strength

.

On the contrary, according to aci-318 code of the United States, when the bearing capacity of the member is controlled by the compression of concrete, the bearing capacity reduction factor phi = 0.65; when the bearing capacity of the member is controlled by the tension of steel, phi = 0.9

.

As shown by the black dotted line in the figure above, there will be a step of safe storage at the junction of compression control and tension control

.

In order to deal with this step, aci-318 introduced a linear transition section between 0.65 and 0.9 from 2002 edition, and defined the starting and ending points of the transition section by steel strain and concrete compression zone height (r9.3.2.2, aci318m-05)

.

According to Mr

.

Bai, Americans are not satisfied with this empirical transition

.

I’m afraid it’s better to use the design value of material strength directly

.

It seems that each of the two methods has its own problems

.

It is difficult to say which is better

.

3

.

When talking about the application of high-strength materials in concrete structures, Mr

.

Bai said straightforwardly that many people want to put their high-strength materials into the specification, but the specification is a systematic project, which can lead the whole body

.

For example, with high-strength steel, the bearing capacity is no problem, how to control the crack? What about deformation control? What about anchorage length? A series of problems need to be coordinated with the existing specification architecture

.

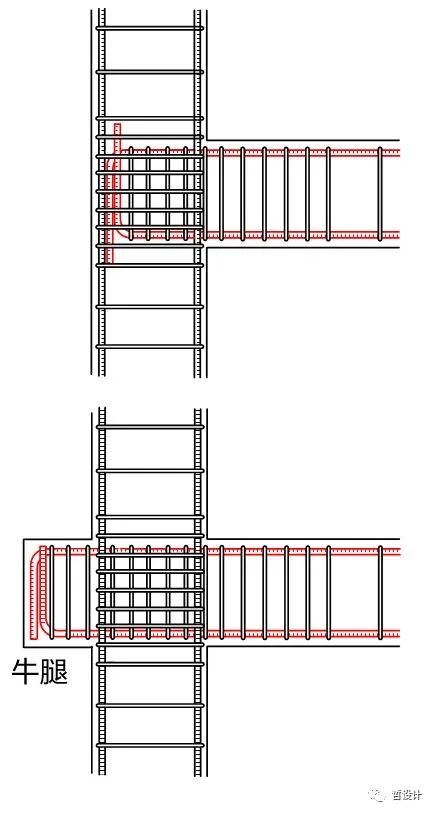

Originally, the anchorage of the steel bar joint area is a headache

.

High strength steel bars must need a longer anchorage length, and the joint area, especially the side column and corner column joints, is more difficult to do

.

How to do if the longitudinal reinforcement of beam is anchored in the joint zone? Mr

.

Bai recalled that park and paulay had been to the Institute of architecture and research in those years

.

When he asked them this question, they actually said: it doesn’t matter

.

Just stretch out a bracket outside the side column or corner column and anchor the longitudinal reinforcement of the beam in the bracket! The status of New Zealand structural engineers is so high [Khan

.

JPG]

.

Back to the point, Mr

.

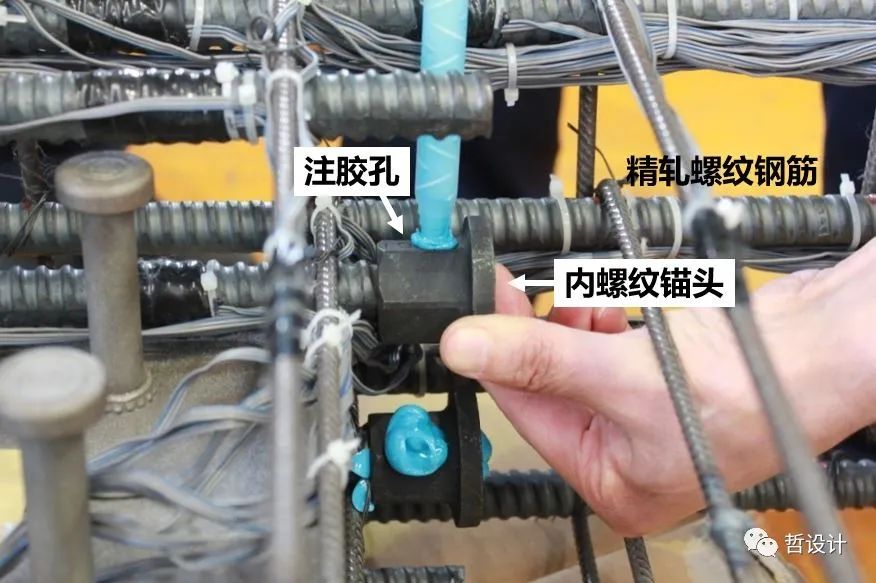

Bai thinks that mechanical anchoring is an effective way to solve this problem

.

I don’t know whether mechanical anchorage is widely used in domestic projects

.

When I did the test in Japan, I used a lot of finish rolled rebar, so mechanical anchorage is very convenient

.

Screw the anchor head with internal thread at the cut-off of the reinforcement, and inject glue into the bolt through the glue injection hole to fill the gap

.

Quetal(2016) doi:10.1061/ (ASCE) st.1943-541x.0001407 in addition to saving anchorage length, another advantage of mechanical anchorage is more clear stress state.

.