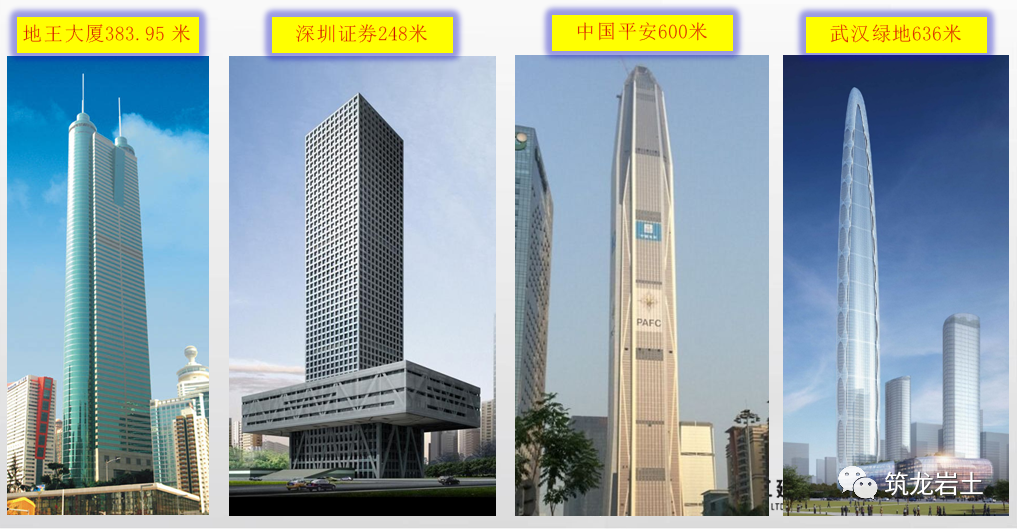

1、 In today’s building environment, super high-rise buildings are more and more common and the height is larger and larger, and the diameter and bearing capacity of the foundation are also larger and larger

.

As the most common foundation type of super high-rise building, the construction quality and progress of cast-in-place pile directly affect the safety of the building and the overall progress of the project

.

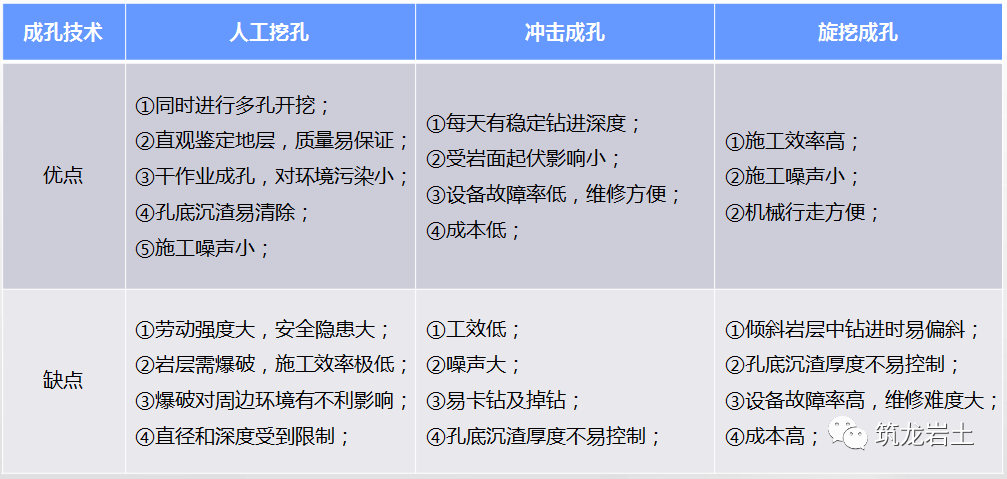

There are many kinds of hole forming technology of cast-in-place pile

.

As a more advanced, efficient and strong rock entry hole forming technology, rotary drilling has a wide application prospect

.

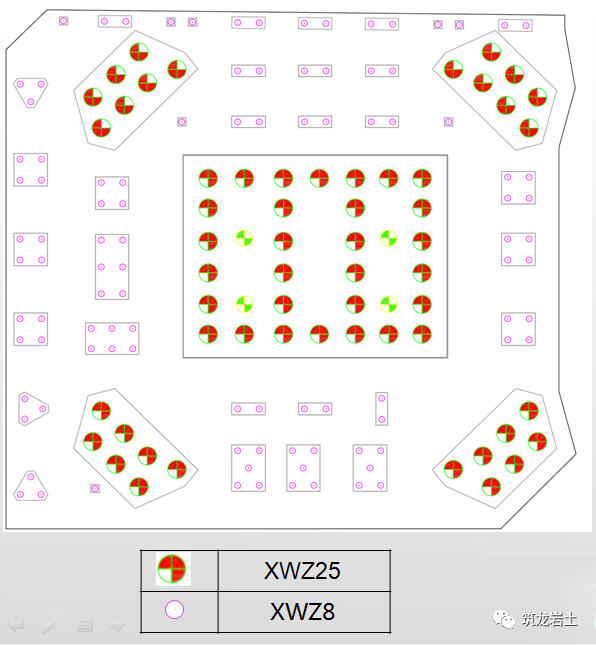

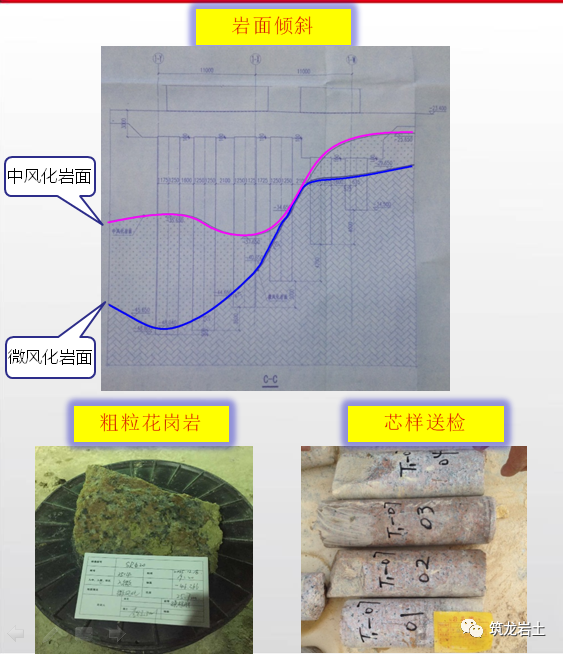

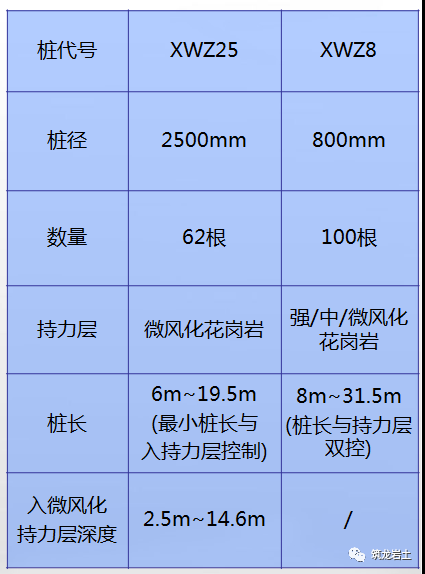

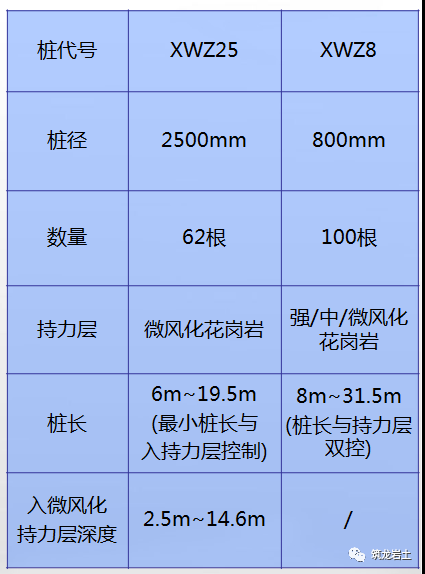

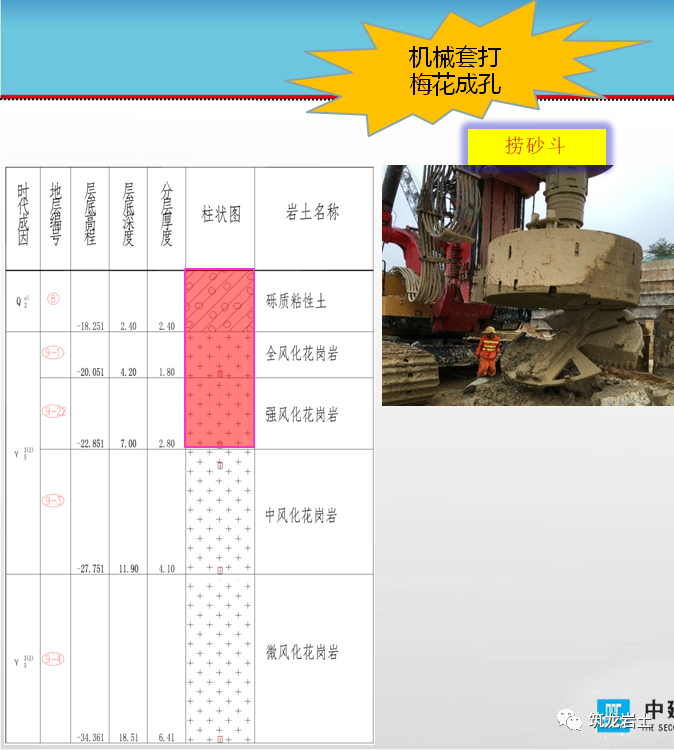

2、 General situation of the project general situation of the project geological situation rock surface fluctuates greatly, the inclination is large, the height difference of single pile rock surface is generally up to 3m, the maximum is 6m; the bedrock is Yanshanian intrusive coarse-grained granite, the structure is basically unchanged, a small amount of weathering fissures are developed; the uniaxial compressive strength of slightly weathered rock is high, up to 90 ~ 130Mpa; the slightly weathered rock surface is shallow, and the depth of pile into slightly weathered rock is up to 2.5 ~ 14.6m; general situation of pile foundation III Comparative analysis of hole forming technology construction comparative analysis of common hole forming technology in rock stratum Table 4

.

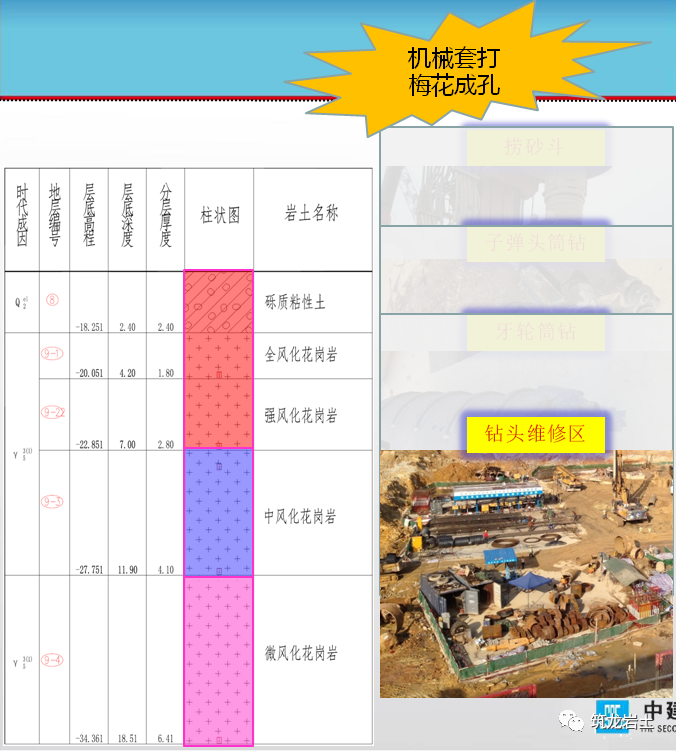

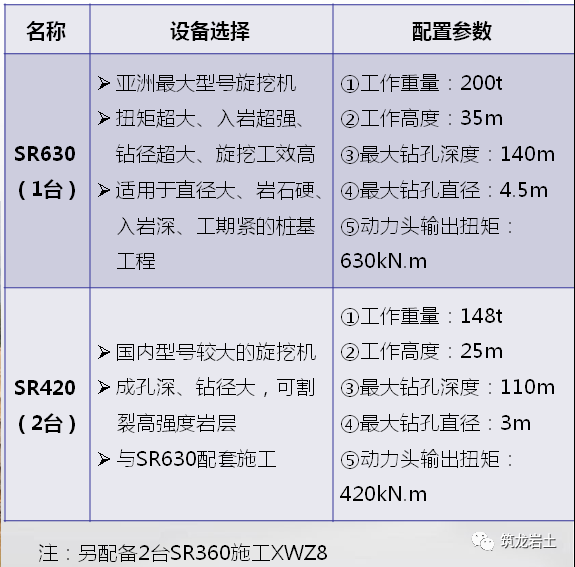

Equipment selection according to the advanced drilling situation combined with the core sample strength test report, judge the location of the project, high rock strength, pile foundation into the rock depth, at least sr420 rotary drilling rig or use punching rig; the project construction period is tight, punching rig efficiency is low, can not meet the construction period requirements; sr420 rotary drilling rig is used According to the trial hole formation of drilling rig, sr420 can drill into the moderately weathered rock stratum, but it can’t drill in the slightly weathered rock stratum; 5

.

Construction process 6

.

Construction method 1

.

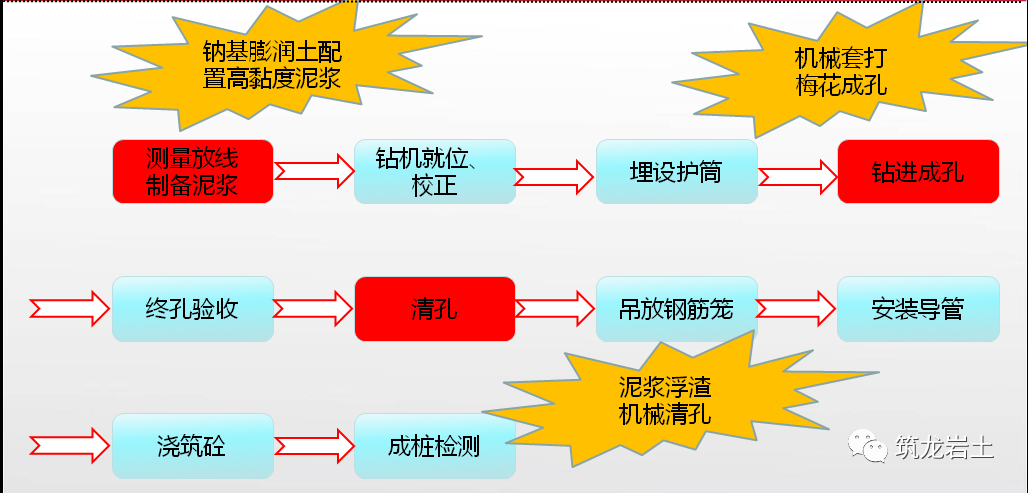

Measurement and setting out, preparation of mud, using sodium bentonite, fully dissolved in water (calcium bentonite and water react easily to form calcium carbonate sediment, affecting the mud quality); capacity of mud pit It is not less than 1.2~1.5 times the volume of pile hole construction at the same time; it is suggested to use finished mud tank, mobile convenience, turnover, mud proportion 1.15~1.3 and viscosity above 23S; 2, drilling machine in place, correct weight of drilling rig, replacement of brick or harden in working face, position of pile hole in hardened area, adjustment of mast and drill pipe angle after drilling, cross hole method for middle hole position, start up Positioning system for positioning and memory; after the middle hole position, the drilling rig shall not be displaced, and the drilling arm shall not change the angle at will; 3

.

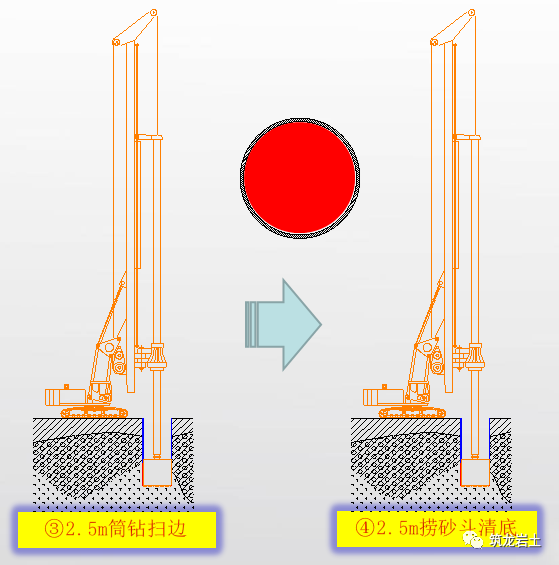

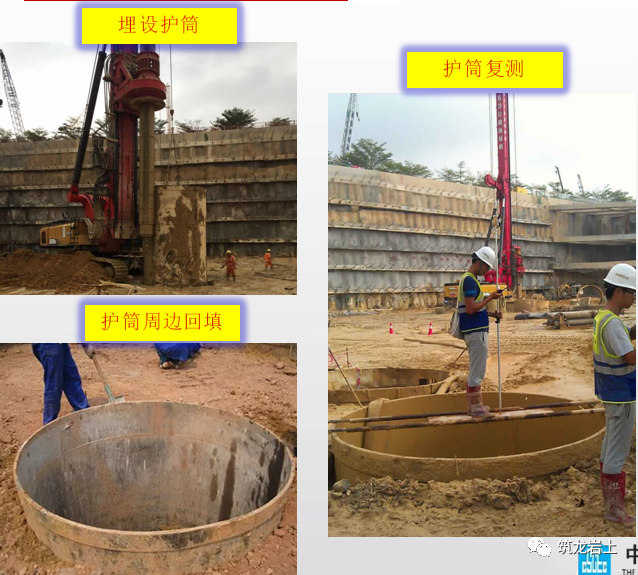

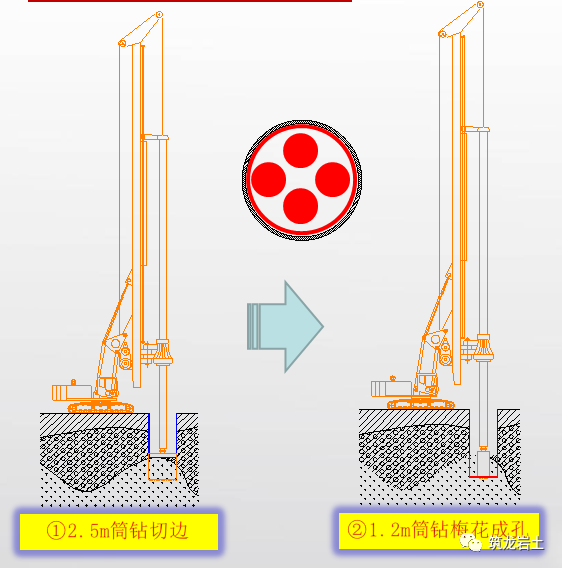

The inner diameter of the embedded casing is generally 20cm larger than the pile diameter; the casing depth passes through the silt layer, sand layer, etc., and can be buried to the strongly weathered layer if conditions permit; after the casing is embedded, the surrounding should be backfilled tightly, which can effectively prevent the casing from sinking; 4 Sr420 drilling rig with sand bailing bucket is used for direct drilling above stratum; sr420 drilling rig with bullet barrel is used for plum blossom drilling in moderately weathered rock stratum; sr630 drilling rig with cone barrel is used for plum blossom drilling in slightly weathered rock stratum; bit loss is fast, 2 ~ 3 bits / set of each specification are equipped for turnover use, and bit maintenance area is set; mechanical casing and plum blossom drilling: ① sr630 and sr420 casing, sr420 is responsible for burying The results show that: 1.2m cylinder drill is symmetrical and plum shaped to form four holes, and the rock is taken out directly by cylinder drill; 4.2.5m cylinder drill is used to sweep the edge and break the remaining rock; 5.2.5m sand bucket is used to remove the gravel (6) circulation drilling, each circulation drilling depth is determined according to the length of the bit that can twist the rock and the lifting weight, the drilling depth of the 1.2m bit is 1.5 ~ 1.8m; (7) drilling efficiency: 5

.

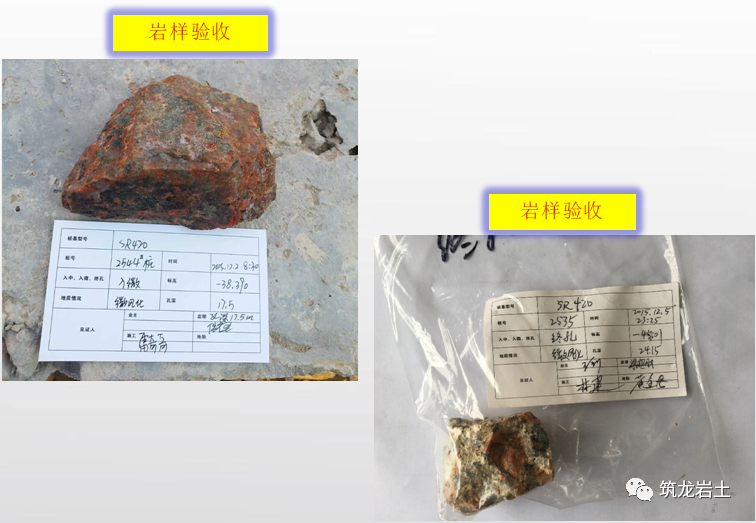

Final hole acceptance: it is easy to judge the rock layer at the bottom of the hole by rotary drilling; the acceptance requires the participation of the owner, supervisor, construction unit and detailed exploration unit; 6

.

The conventional hole cleaning technology is positive circulation hole cleaning The new technology is mud scum and mechanical hole cleaning

.

High quality sodium bentonite is used to make slurry artificially, and tap water is used to make bentonite into high viscosity and high performance slurry with specific gravity of 1.15 ~ 1.3 and viscosity of more than 23S according to the ratio of water: bentonite: flake alkali = 1000:80 ~ 120:1.5 ~ 2; after finishing the hole, the ground small stones are repeatedly cleaned (3 ~ 5 times) by sand bucket, and the manipulator is required to have good technology and high quality to clean the small stones completely

.

Under the static balance, the fine sand particles are completely suspended in the mud and do not precipitate, so as to remove the sediment at the bottom of the pile and ensure the quality of the pile

.

7

.

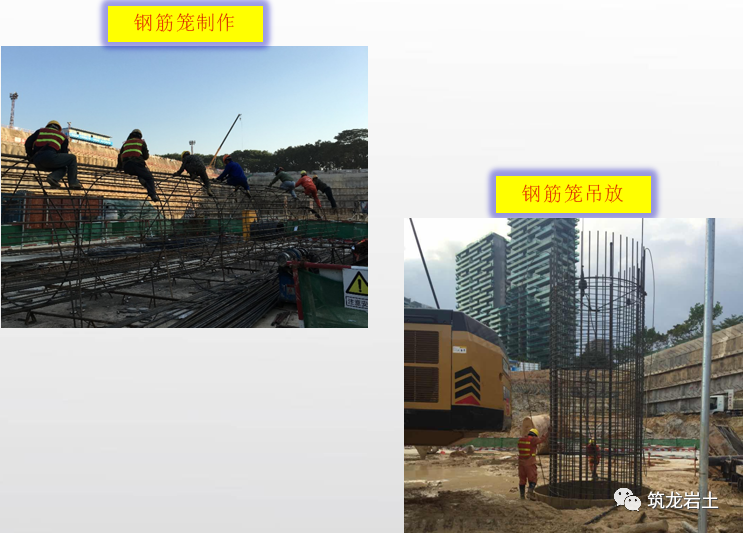

Strengthen the welding of the lifting points of the reinforcement cage to ensure the stability of the lifting; avoid the hole collapse caused by the collision of the reinforcement cage with the hole wall; 8

.

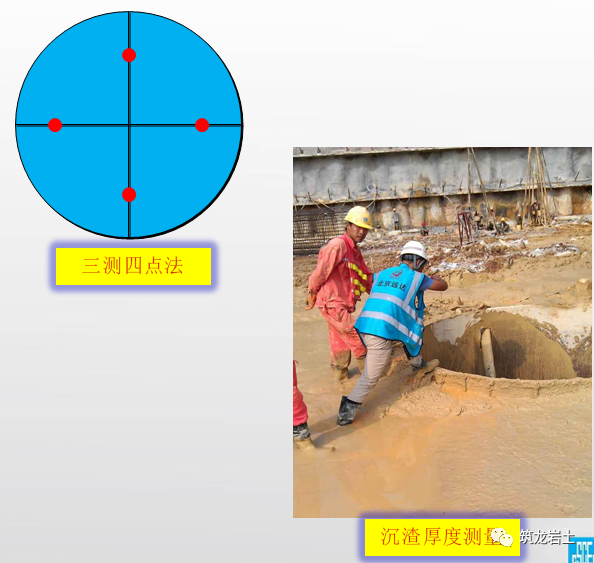

Check the sediment thickness by “three measurement and four point method” for sediment thickness measurement; use the measuring rope to measure the four uniform points in the southeast and northwest of the pile body after the completion of the hole, after the reinforcement cage is lowered and before the pouring, if the sediment thickness of the three measurements and four points is less than 50 mm And the difference is basically unchanged before concrete pouring; the sediment thickness measured before concrete pouring does not meet the design requirements, re drill pipe cleaning to ensure that the sediment thickness meets the design requirements; 9

.

The distance between the pile detection pipe and the pile bottom shall be controlled at 30-50cm, and the buried depth of the pipe after initial pouring shall be controlled at not less than 1m; the buried depth of the pipe during normal pouring shall be greater than 2m and less than 6m; core pulling shall be used to detect the sediment thickness The thickness of the sediment of the three core samples is 5mm, 10mm and 5mm respectively; copyright notice: the content of this wechat comes from the second company of China Construction Third Bureau, and the copyright belongs to the original author

.

If the copyright of the work is involved, please contact us, and we will negotiate the copyright issue or delete the content as soon as possible! This is the original author’s personal view, which does not mean that the official account agrees with his views and is responsible for his authenticity.

.