Durability: the service life of the main structure can reach more than 90 years.

Product introduction of Hubei Mingsen light steel villa seismic resistance: it can resist rare earthquakes of magnitude 9 and is suitable for areas with seismic strength of more than magnitude 8.

Fire resistance: according to different design According to the calculation, the fire resistance time can reach 1 ~ 4 hours.

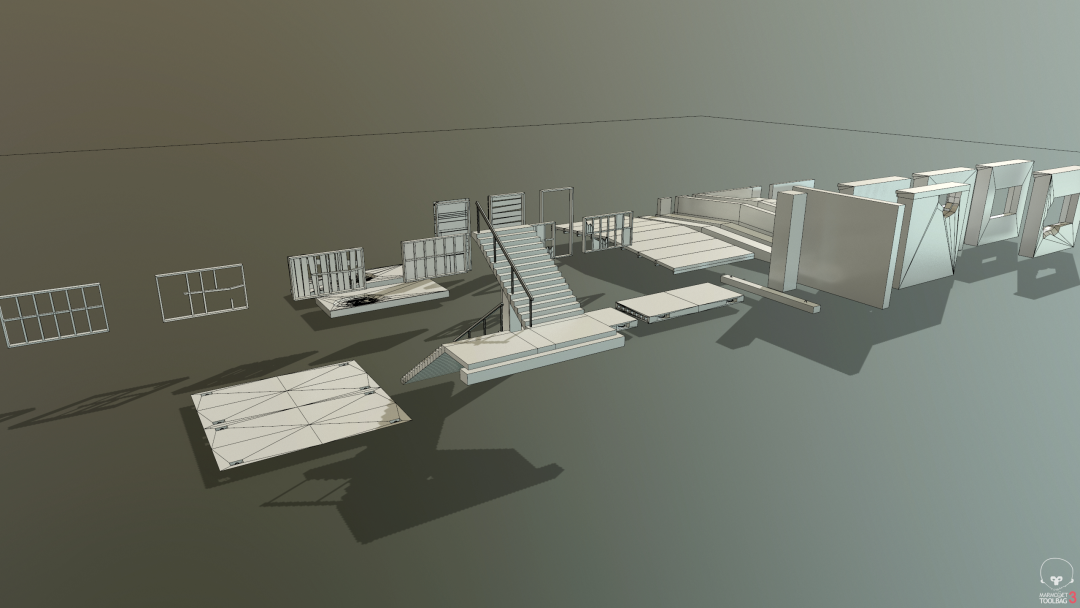

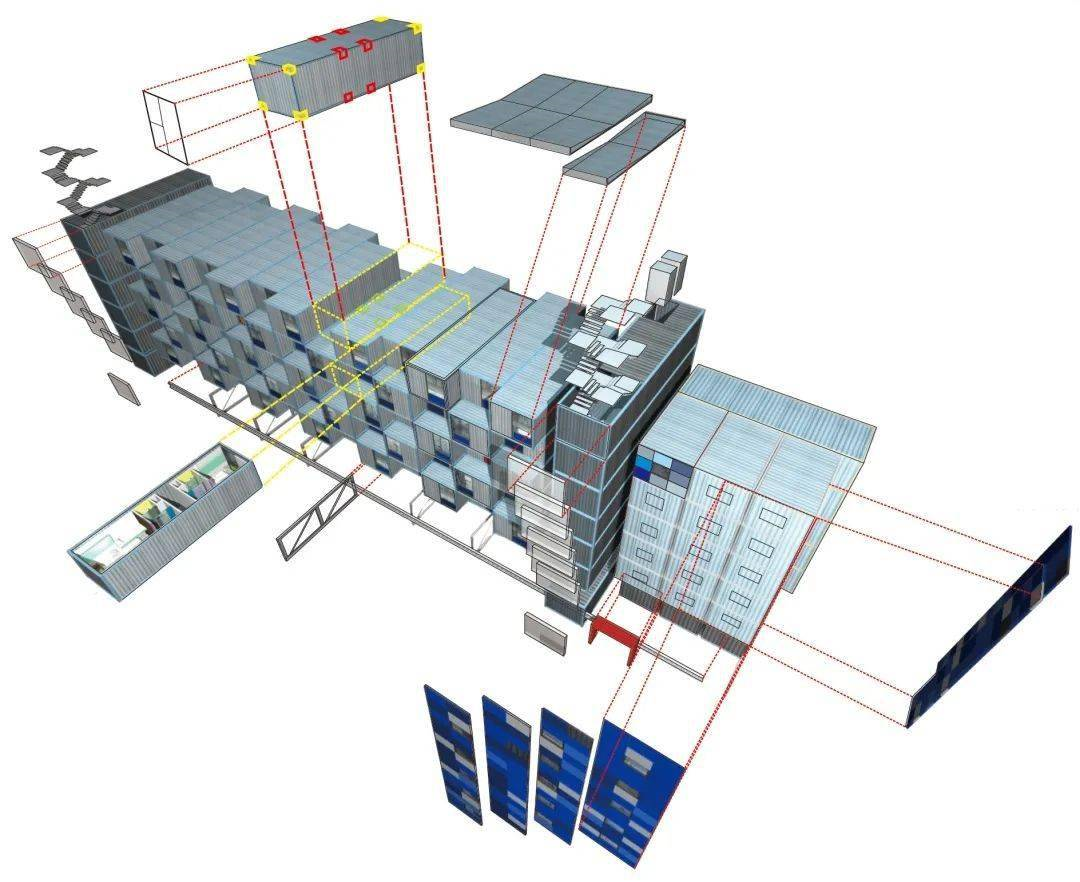

This also means that the construction of standardized production system for prefabricated buildings has been completed! Span from 0 to 1 In 2020, the guide to the dimensions of main components of steel structure housing issued by the Ministry of housing and urban rural development took the lead in specifying the dimensions of steel structure components such as beams, columns, supports and low-rise cold-formed thin-walled steel sections; Recently, the guidelines on the dimensions of main components of prefabricated concrete structure residential buildings and the guidelines on the dimensions of main components of prefabricated decoration of residential buildings released at the same time respectively describe the dimensions of precast concrete components such as floor slab, air conditioning board, stair, wallboard, beam and column, as well as prefabricated partition wall and wall system, prefabricated floor system, prefabricated ceiling system The dimensions of components such as integrated kitchen are specified.

Construction period: the standardized assembly operation of light steel structure residence is simple and fast, saving two-thirds of the construction period compared with brick concrete structure.

The implementation needs joint efforts of many parties At the beginning, the Ministry of housing and urban rural development proposed to build “1 + 3” The purpose of standardized design and production system is to fully open up the links of prefabricated housing design, production and engineering construction, promote the coordinated development of the whole industrial chain, solve the connection between the standardized design of prefabricated buildings and the application of standardized components and parts, provide strong technical guidance for designers, and promote the design method of less specifications and more combinations; at the same time , by clarifying the specific dimensions of general standardized components and parts, gradually guide the transformation of customized and small-scale production mode to standardization and socialization, guide production enterprises, design units and construction enterprises to coordinate and unify the common dimensions of components and parts, comprehensively improve the industrial production, design and construction efficiency of new buildings, and promote the production of prefabricated houses The industry is moving towards standardization, scale and marketization.

Experts in the industry highly praised the preparation and official release of the dimensional guidelines for the three main components and parts, and considered it very timely and feasible “By 2035, China will make remarkable progress in the coordinated development of intelligent construction and building industrialization, greatly improve the innovation ability of enterprises, significantly enhance the overall advantages of the industry, take the lead in the world in terms of core competitiveness, fully realize building industrialization, and become a world power of intelligent construction” As an important step of the goal, it is of positive significance to accelerate the industrialization of new buildings represented by prefabricated buildings.

How to implement them and gradually improve them in practice to further achieve the initial purpose has become the focus of more attention in the industry.

At present, there are still many problems in the industry, such as lack of systematic integration of various disciplines, narrow knowledge of various professionals, lack of professional knowledge of workers in the construction industry and on-site construction For a series of practical problems such as weak assembly, many interviewees gave implementation suggestions from different angles.

Sound insulation: the sound insulation capacity of the external wall can reach 65dB, and the sound insulation volume of the internal wall can reach 45dB.

Thermal insulation: the thermal resistance of the 200mm thick composite wall can reach 3.2m2k/w, which is 11 times that of the brick wall with equal thickness.

Energy saving: new thermal insulation and heat insulation materials are adopted, which requires more energy for heating and refrigeration than traditional ones Building energy saving 65% occupancy rate: the utilization area of light steel integrated house increases by 5% ~ 13% compared with traditional buildings.

Environmental protection: steel structure materials can be 100% recycled, and most of other supporting materials can be recycled.

Wind resistance: it can resist hurricanes of 70m / S and wind resistance grade of more than magnitude 12.

Now the size guidelines for the three main components and parts have been officially released.

Up to now, the dimensional guidelines for three main components and parts in the “1 + 3” standardized design and production system have been prepared and officially released.

One year later, significant progress has been made in the construction of the above “1 + 3” standardized design and production system.

The main business of the company: 1 Design and construction of light steel structure villa two Design and construction of wooden structure villa 3 Design and construction of heavy steel structure villa 4 Garden, landscape design and construction 5 Indoor and outdoor decoration, decoration, whole house integrated decoration and customization 6 Sales of new environmental protection building decoration materials.