On the day before the Spring Festival holiday, Wuhu natural resources and Planning Bureau issued the transfer notice of No

.

2105 residential land in the East Wanchun plate, which required that the land must be constructed with prefabricated construction technology! Is this noun familiar? Since 2020, there have been three residential lots in Wuhu City, which require all prefabricated buildings

.

They are: plot 1, Zhanbei Road, Jinghu District (Anhui Tonghai real estate No

.

2017), plot A1, Jiuhua South Road, Yijiang district (Zhongcheng No

.

2019)

.

Click to learn the details of Tonghai No

.

2017 plot in Jinghu District

.

Click to learn the details of Zhongcheng No

.

2019 plot in Yijiang district

.

What is prefabricated building? How is it different from traditional residential buildings? What impact will it have on the development of Wuhu property market? What is prefabricated architecture? Nowadays, the mainstream construction method of residential buildings in China is cast-in-place reinforced concrete, while prefabricated buildings, like the Lego building blocks, prefabricate some or all components in the factory, and then transport them to the construction site for assembly

.

After the prefabricated components are transported to the construction site, the splicing and pouring of reinforced concrete will be carried out, so the assembly room is very safe

.

As a concept put forward in the early 20th century, tuyuan network prefabricated building is widely respected because of its advantages of fast construction speed, low production cost and modern technology

.

The proportion of prefabricated buildings in the United States, Japan, Europe and other developed countries has reached 70% – 90%, while the domestic prefabricated buildings have just started

.

In xiong’an New District, all steel frame, prefabricated wall, integrated house and other factory building components are widely used in the project, which reduces the environmental pollution and loss caused by on-site construction and improves the work efficiency

.

Tuyuan network: the Empire State Building, Sydney Opera House, Hong Kong International Financial Center, Wuyue Plaza, Haiyan, Zhejiang and so on are the landmark buildings in New York

.

There are numerous examples of prefabricated buildings, whether they are public buildings or residential buildings

.

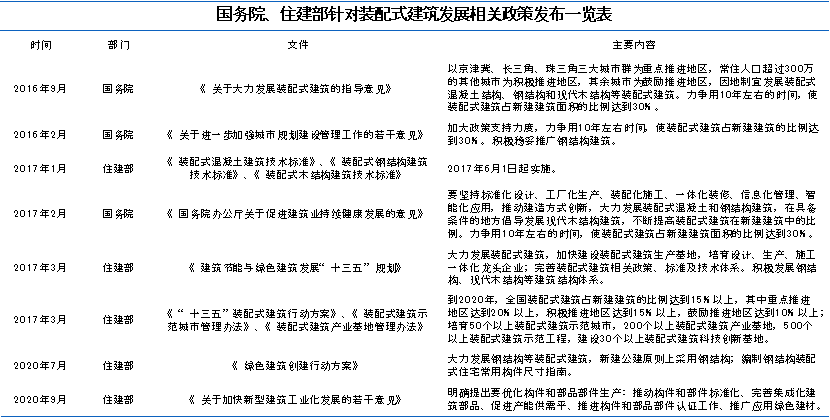

Tuyuan.com in 2016, prefabricated buildings in China ushered in the first year of the policy, “guidance on vigorously developing prefabricated buildings” was officially released, which clearly put forward the specific goal of “strive to use about 10 years to make the proportion of prefabricated buildings in the new building area reach 30%”

.

In the next four years, from the national level to the local governments, a series of construction, testing, evaluation and other standard documents have been issued

.

Driven by the policy, prefabricated construction may become an inevitable trend in the development of the construction industry

.

In terms of classification, prefabricated concrete structure buildings are mainly used in residential buildings, office buildings, teaching buildings, hospitals, etc., which is the most permeable prefabricated structure at present; steel structure buildings are mainly used in large-span factories, gymnasiums, super high-rise office buildings, etc.; wood structure and its market are small

.

From the perspective of application, prefabricated housing is mainly used for commercial housing, public buildings and affordable housing

.

What are the benefits of prefabricated buildings? Prefabricated building has incomparable advantages in building quality, construction period, energy conservation and environmental protection

.

What is the difference between prefabricated architecture and traditional architecture? 1

.

It is helpful to improve the construction quality

.

The traditional construction method is highly dependent on labor, the quality of workers is uneven, quality accidents occur from time to time, and the quality monitoring is difficult

.

The quality of prefabricated building components produced in prefabrication plant is more controllable, and the overall safety level, fire resistance and durability of residential buildings are improved

.

2

.

It is helpful to speed up the progress of the project

.

Prefabricated parts of prefabricated construction are transported to the construction site for assembly after the factory production is completed, which is different from the traditional cast-in-place construction

.

There is no conflict between assembly construction and other construction, the two can be carried out at the same time, and the construction schedule and cycle are shorter than the previous cast-in-place construction; the overall delivery is 30% – 50% faster than the traditional construction

.

It is helpful to adjust the supply relationship, improve the listing speed of real estate, and slow down the current situation of insufficient market supply

.

After the popularization of the industry, it can reduce the construction cost and effectively restrain the house price

.

4

.

It is conducive to civilized construction and safety management

.

There are a large number of workers in the traditional operation site

.

Now a large number of site operations are moved to the factory, which greatly reduces the incidence of site safety accidents

.

5

.

Energy saving and environmental protection, reduce the surrounding impact; prefabricated building site without fire, water, dust, health does not disturb the people, can effectively reduce energy consumption and environmental pollution; in addition, prefabricated building due to its removable characteristics can also achieve reuse

.

Compared with the traditional pouring construction, the prefabricated construction can reasonably arrange the production of prefabricated parts according to the actual construction needs, and effectively reduce the construction cost and redundant consumption

.

Secondly, in terms of labor consumption, as the labor consumption of prefabricated construction is mainly concentrated in the installation of prefabricated parts, the on-site assembly construction is highly mechanized, reducing the number of on-site construction and management personnel

.

How to produce and construct prefabricated building? How to produce prefabricated building slab? Take prefabricated building slab as an example, the production process: steel mold making → steel bar binding → concrete pouring → demoulding

.

After the fabricated components are manufactured and classified in the factory, they are ready to be transported to the construction site

.

For example, after the construction of the first floor, the columns on the upper floor are hoisted first, and then the main beam, secondary beam and floor are hoisted

.

After the lifting of prefabricated components, the steel bars at the connecting parts are bound, and the cast-in-place layer of nodes and beam slab is poured at last

.

The site construction process of prefabricated structure is the lock type splicing method on the external wall, and some are butted with steel skeleton

.

Then fill it, and finally add the sealing strip sealant

.

When building the interior wall, first install the skeleton, and then directly splice, which is convenient and fast, and also convenient for subsequent demolition and modification

.

Compared with the traditional construction method, the prefabricated building can be more convenient and efficient, and can save manpower and materials

.

Prefabricated building has many advantages and high technology content

.

Of course, it has high requirements for industrial production and scientific construction

.

In the future, prefabricated building will be more used in the residential construction of Wuhu

.

In January of this year, Wuhu Municipal government issued the implementation opinions on promoting the development of prefabricated construction industry

.

According to the latest “opinions”, by 2025, the city will cultivate and introduce more than 3 design and construction integrated enterprises, and form prefabricated construction enterprises integrating design, production and construction; cultivate 5 provincial prefabricated construction industrial bases; and the prefabricated buildings in the city will account for more than 30% of the new construction area

.

From 2020, prefabricated buildings will be arranged to the maximum extent according to the actual situation in the new industrial projects and public service facilities

.

The transfer plan of operating land is to arrange prefabricated buildings according to 15% of the capacity area, and then the total amount will increase year by year

.

By 2025, the construction area of prefabricated construction projects will not be less than 30% of the planned transfer area

.

If the real estate development project is constructed by assembly, the construction area of the prefabricated part of the external wall does not exceed 3% of the total planning construction area, it can not be included in the volume ratio accounting of the transaction plot

.

When the image progress of the newly-built prefabricated commercial housing project reaches ± 0, it can apply for the pre-sale permit of commercial housing according to the regulations

.

The newly-built commercial housing with prefabricated construction method can rise appropriately when the price is put on record.

.