The prefabrication rate of prefabricated buildings is greater than 30%, and the prefabrication and assembly rate is greater than 50%.

The storage rack of components shall have sufficient anti overturning performance.

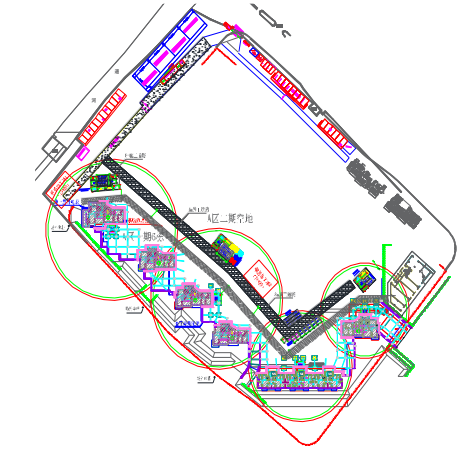

The selection and site layout of tower crane are very different from those before.

design unit: Wuxi Chenggui Design Co., Ltd.

2.

If the crane is selected according to 1.5 times, the surplus will have a great waste on the selection of tower crane, and the machinery rental fee may be doubled.

Stereotyped grids are set on both sides of the road and signs are hung.

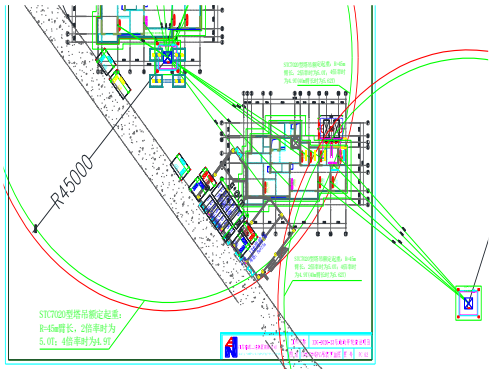

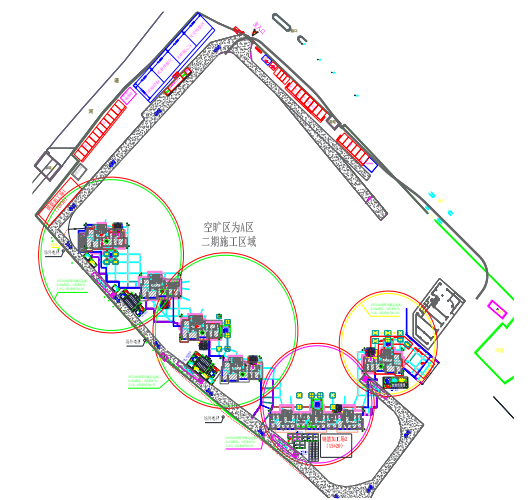

The layout of the construction site is 1 Foundation and below 5 floors.

mainly includes precast concrete (PC) component types: Precast shear wallboard, precast laminated floor slab and precast stair slab.

There are more and more prefabricated buildings, and more tower crane leasing units are transforming to provide large-scale tower cranes.

For PC component driving road, the turning radius shall not be less than 15m, the driving road width shall not be less than 4m, the channel shall be connected in a circular way, stereotyped grids shall be set on both sides of the road, signs shall be hung, and it is forbidden to cross the line.

The construction storage yard is planned in advance and clearly marked with bright yellow paint.

3.

Safety review of main structure of tower crane wall attachment point.

The skids shall be on the same vertical line and of equal thickness.

The development trend of the construction industry is that the scale is becoming more and more large-scale, energy-saving and industrialized.

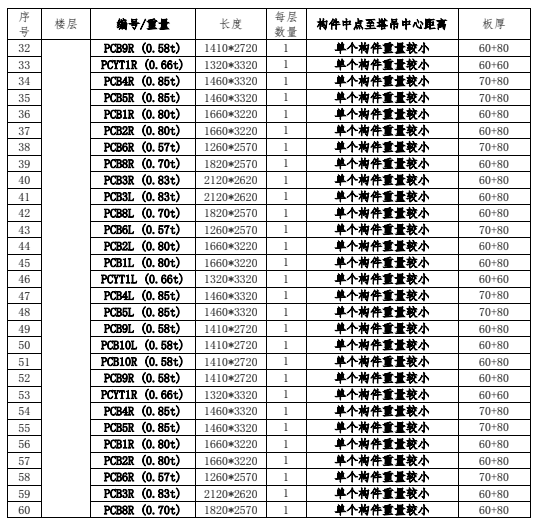

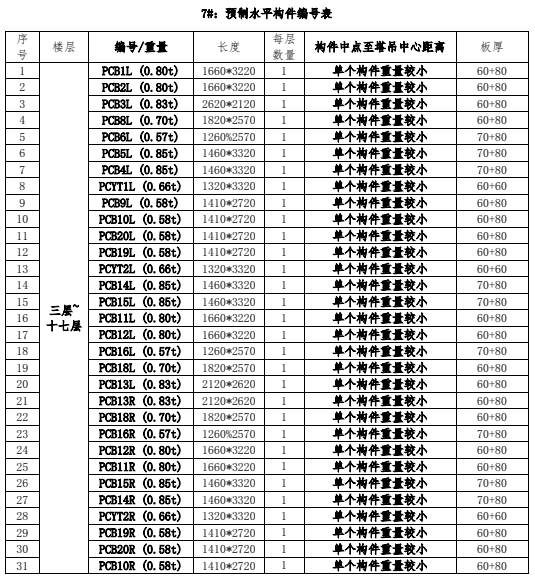

PC component installation unit: overview of prefabrication rate of Suzhou Xujie Construction Technology Co., Ltd For the first batch of 6 buildings, the statistical summary table and schematic diagram of prefabricated concrete (PC) component types are as follows: (1) summary table of prefabricated vertical components (2) summary table of prefabricated horizontal components (3) summary table of prefabricated stair components.

(4) The storage of peripheral materials and consumables shelves, the special container for PC revolving materials and consumables is welded by angle steel l100x10, and the wooden board is laid horizontally for isolation.

Components shall be stacked with a certain hook binding spacing.

Construction unit: Wuxi aizhihong Real Estate Co., Ltd.

3.

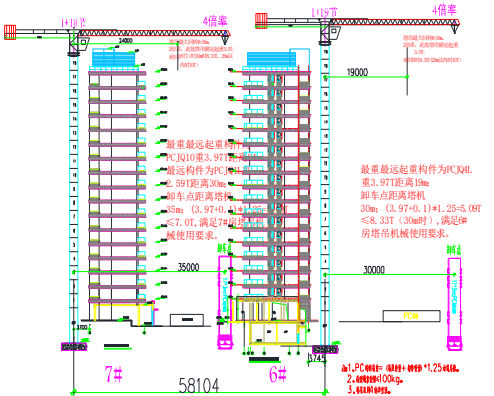

The flat head tower crane has certain advantages in tower group operation and anti-collision: the arm length can be shortened to 30m, the attachment spacing is large, the attachment is small, the suspension above the attachment is large, the attachment layout can be reduced and the temporary attachment wall can be set less.

The components hoisted first shall be stacked on the outside or on the upper layer, and the numbered or marked side shall face the side of the channel.

The skid of each layer shall be on a vertical line, and the fulcrum is generally the position of lifting hole.

Each PC component storage yard is prepared according to 1 / 3 of the building area; The preferred storage yard shall avoid the impact and reinforcement on the basement, and minimize the tower company’s line of sight and hoisting time when it is convenient for installation; The base soil layer of the storage yard shall be hardened and open drainage ditches shall be set around.

The thickness of skids shall be higher than the height of lifting rings.

When unloading, it is advisable to enter the basement roof at the front of the vehicle to avoid the impact of the whole vehicle on the basement roof; Storage sites shall be set up according to specifications, varieties, use parts and hoisting sequence; The storage site shall be set within the effective lifting range of hoisting equipment, and channels shall be set between stacks; The components with poor lateral stiffness, high center of gravity and narrow bearing surface shall be placed in place.

The skid between layers shall be leveled and padded.

Do not cross the line.

3.

The skids between components shall be on the same vertical line and the thickness shall be equal.

Selection of tower crane model 1.

2.

4.

8.

Single weight of stair plate: ≤ 2t3.

Basic requirements for on-site transportation road and storage yard setting 1.

Pay attention to the effective arm length of tower crane in tower group construction and later development building, whether it touches the buildings and scaffolds in the first development area, and whether it touches the existing buildings around; The main building covered by tower crane shall not have intersection blind area.

6.

The lowest skid shall be full-length.

The support shall be provided by PC manufacturer.

The reasonable selection of tower crane model is more important to the hoisting turnover speed, construction period and construction safety.

2 when the main body is more than 5 floors, the site layout shall timely backfill the foundation pit of the underground garage and connect the construction road.

The “wuheng” health technology fine decoration residential project invested by Wuxi aizhihong Real Estate Co., Ltd.

Single weight of shear wall: ≤ 3.97t2.

(3) The stacking ladder section of prefabricated stair slab shall be stacked horizontally in layers and models (left and right).

Summary 1.

9.

3pc component stacking yard PC components are unloaded by transport vehicles and stacked in the PC special storage yard of each building, classified and stacked according to the specified sequence.

The supports themselves shall be firm and shall not swing left and right or loosen after support.

If the tower crane foundation is constructed before the surrounding area, pay attention to the excavation safety distance from the surrounding sump, well, etc.

The laminated plates are stacked with 4 or more fulcrums.

Select high-quality equipment suppliers, and the quality of equipment, maintenance operation and construction personnel can better ensure the safe operation of the project.

The stacking position shall be within the rotation radius of the installed lifting machinery as far as possible, and the hoisting direction shall be taken into account to avoid turning and re handling during hoisting.

Because all the main buildings are located on the basement, there are settlement post cast strips around the main building.

The distance between tower crane and main building shall ensure accessibility during installation, and the impact of cab, tower crane frame, front and rear boom on scaffold, protruding building and construction elevator during disassembly, Smooth disassembly.

Drivers, commanders and lifting personnel shall be trained and qualified by relevant departments before they can work with certificates, which can better ensure construction safety..

For the distance between the maximum component and the tower crane position, the maximum torque of unloading point, storage yard point and installation point shall be calculated respectively, and the weight of hook, spreader and other tools shall not be omitted in the calculation.

Pay attention to the selection of 2-fold or 4-fold lifting rate in the lifting performance of tower crane.

The local safety supervision department and experts shall be consulted in advance to reasonably determine the hoisting safety factor of the tower crane on the premise of meeting the local safety supervision acceptance and construction scheme demonstration.

All slings and slings must have certificates and inspection reports before they can be put into use.

The number of stacking layers of precast composite floor slab shall not be greater than 6 (according to the design and relevant requirements).

Under the condition of meeting the sales node objectives, the pure basement beside the main building shall be constructed synchronously or as soon as possible.

Let’s take a look through an engineering example.

Single weight of laminated plate: ≤ 2t2.

supervision unit: Shanghai Construction Engineering Consulting Co., Ltd.

and constructed by Jiangsu Nantong Second Construction Group Co., Ltd.

7.

The components shall be stacked with a certain hook binding spacing.

(1) For the stacking of prefabricated shear walls, PC wall panels shall be placed vertically and welded with 6#, 10# channel steel.

Click the blue word above to follow us! With the large-scale promotion and landing of prefabricated buildings, the traditional construction technology has also changed.

During stacking, the spacing between adjacent components shall not be less than 500mm.

During stacking, the spacing between adjacent components shall not be less than 200mm.

5.

4.

The components shall be stacked in sequence according to the model and hoisting sequence.

construction unit: Jiangsu Nantong Second Construction Group Co., Ltd.

The hoisting safety factor of tower crane selected for prefabricated buildings is currently required to be 1.5 times by the state, provinces and cities.

After the PC board is vertically placed into the special support, both sides are pressed with wooden wedges.

When setting tower foundation piles for tower crane foundation, pay attention to the construction distance from the main building and basement engineering piles.

Each stack shall not exceed 3 pieces.

Use wood as cushion block to ensure that the board surface is not damaged.

The supporting points of wall panels shall be set at both ends of the bottom of wall panels, and the stacking site shall be flat and solid.

The foundation bearing capacity of tower crane foundation shall meet the requirements for the use of tower crane machinery.

Components shall be stacked stably, and skids shall be placed at the bottom.

PC component production unit: Changzhou Jietong prefabricated construction Co., Ltd.

Special points for attention in tower crane selection 1.

2.

5.

Summary of maximum weight of each component 1.

(2) Stacking of prefabricated laminated slabs the stacking layers of prefabricated laminated slabs should not be more than 6, and the stacked slabs should be stacked stably with 4 or more fulcrums.

4.

The stacked components shall be separated by skids.

Prefabricated building construction and tower group operation shall be normal.

In addition to the skids at both ends, supports shall also be erected or temporarily fixed with supports.

4 stacking of fabricated components each PC special storage yard is composed of four areas, including peripheral material and consumable shelves, laminated plate stacking area, stair stacking area and PC wallboard stacking area.