Building explosion-proof, electrical explosion-proof and equipment explosion-proof are required every year! Follow Niu girl and get everything done! Code for fire protection design of buildings gb50016-2014 (2018 Edition) explosion proof of plants and warehouses 3.6.1 class A and class B plants with explosion risk should be set independently and should be open or semi open.

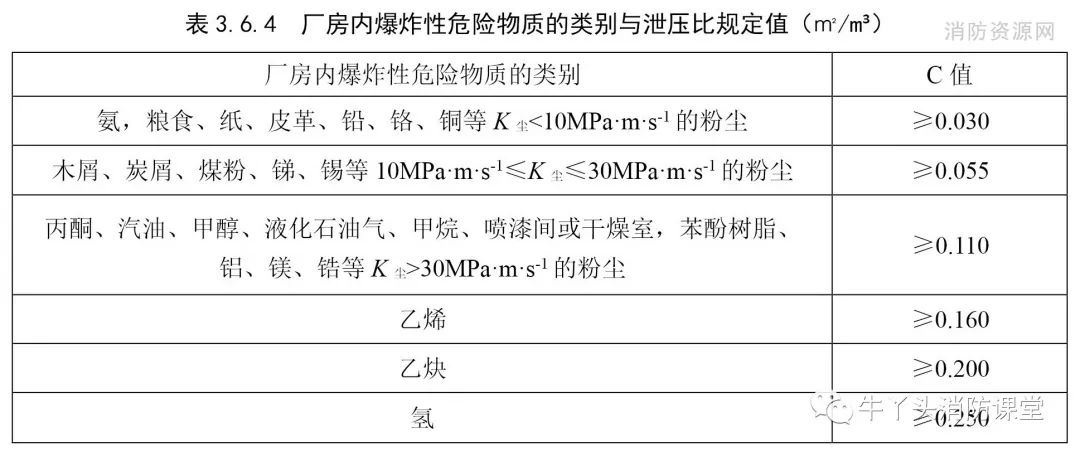

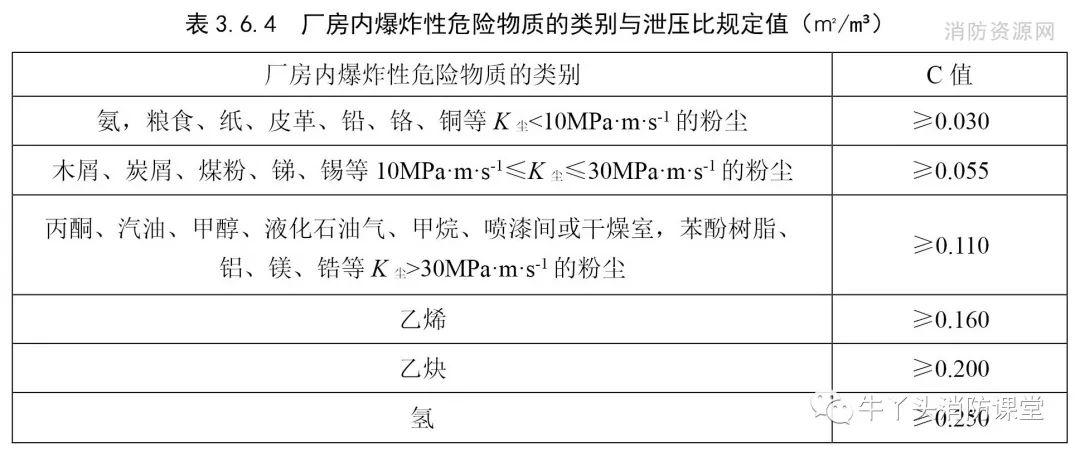

However, when the length diameter ratio of the power house is greater than 3, the building should be divided into multiple calculation sections with the length diameter ratio not greater than 3, and the common section in each calculation section shall not be used as the pressure relief area: Where: a – pressure relief area (m) ²); V – volume of plant (m) ³); C – pressure relief ratio, which can be selected according to table 3.6.4 (m) ²/ m ³)。 Note: 1 the length diameter ratio is the ratio of the product of the longest dimension in the geometric overall dimensions of the building plane and its cross-sectional perimeter and 4.0 times the building cross-sectional area.

9.2.6 the thermal insulation materials of heating pipelines and equipment in the building shall meet the requirements of The following provisions: 1 for class A and class B plants (warehouses) , incombustible materials shall be used; 9.3.2 the exhaust pipes in places with explosion danger in the plant shall not pass through the firewall and the partition wall of rooms with explosion danger.

9.2.2 open fire and electric radiator are strictly prohibited for heating in class A and B plants (warehouses).

2K dust refers to the dust explosion index.

The trench should take effective measures to prevent the accumulation of combustible gas, combustible vapor, dust and fiber in the trench, and should be sealed with fireproof materials at the connection with adjacent plants.

two The internal surface of the plant emitting combustible dust and fiber shall be flat, smooth and easy to clean.

The partition wall of the door bucket shall be a fire partition with a fire resistance limit of no less than 2.00h, and the door shall adopt class a fire door and shall be set misplaced with the door of the staircase.

The equipment with explosion risk should be arranged away from the main load-bearing components such as beams and columns of the plant.

3.6.13 for silos with dust explosion risk, the top cover plate shall be equipped with necessary pressure relief facilities.

It has continuous ash cleaning function or regular ash cleaning function, and the air volume is not greater than 15000m ³/ h.

9.3.6 dust collector and exhaust fan for treating explosive dust shall be set separately from other ordinary fans and dust collectors, and shall be arranged in groups according to a single dust.

When insulating materials are used as the overall surface layer, anti-static measures shall be taken.

9.3.3 the air supply and exhaust pipes in class A, B and C plants shall be set in layers.

Explosion proof measures shall be taken for other grain storage facilities with dust explosion risk.

When the air supply fan is arranged in a separate ventilator room and anti reflux facilities are set on the air supply main pipe, ordinary ventilation equipment can be adopted.

3.6.10 staircases, outdoor stairs or areas with explosion risk in explosion risk areas shall be connected with adjacent areas Protective measures such as door bucket shall be set at the door.

The pressure relief facilities shall be set away from densely populated places and main traffic roads, and shall be close to the parts with explosion risk.

Wet dust collector shall not be used for dust that may form explosion in contact with water.

9.3.4 Explosion proof ventilation equipment shall be adopted for the air supply and exhaust system of rooms with flammable and explosive hazardous substances in the air.

3.6.2 Pressure relief facilities shall be set in the plant with explosion risk or the parts with explosion risk in the plant.

9.3.8 pressure relief devices shall be set for dust collectors, filters or pipelines that purify or transport dust and debris with explosion risk.

3.6.6 Class a plants emitting heavier combustible gases and vapors and class B plants with dust and fiber explosion hazards shall comply with the following provisions: one Non sparking ground shall be used.

3.6.11 The pipes and ditches of plants that use and produce class A, B and C liquids shall not be connected with the pipes and ditches of adjacent plants, and the sewers shall be provided with oil separation facilities.

The combustible gas, steam, dust or fiber emitted in the production process can cause combustion when contacting with the surface of heating pipes and radiators; 2 the dust emitted in the production process can cause spontaneous combustion, explosion or explosive gas in the plant under the action of water and steam.

The pressure relief area of the working tower and the upper corridor of the grain silo shall be calculated and determined according to the provisions of article 3.6.4 of this code.

3.6.3 pressure relief facilities should adopt light roof panels, light walls, doors and windows easy to relieve pressure, and safety glass and other materials that will not produce sharp fragments during explosion.

Dry dust collectors and filters with a dust storage capacity of less than 60kg in the dust hopper can be arranged in a separate room in the plant, but shall be separated from other parts by fire partition with a fire resistance limit of not less than 3.00h and floor slab with a fire resistance limit of 1.50h.

The dry dust collector and filter for purifying explosive dust shall be arranged on the negative pressure section of the system..

If it is necessary to pass through, incombustible materials shall be used for thermal insulation.

9.3.5 air containing combustion and explosion hazardous dust shall be removed without spark before entering the exhaust fan Dust collector shall be used for treatment.

3.6.8 The general control room of class A and class B plants with explosion risk shall be set independently.

The air containing combustion or explosion hazardous dust and fiber in class C plant shall be purified before recycling, and the dust concentration in the air shall be lower than 25% of its lower explosion limit.

The warehouse of articles that will burn and explode when wet shall take measures to prevent water immersion.

3.6.5 for class a plants emitting lighter combustible gas and combustible vapor, light roof panels should be used as the pressure relief area.

If necessary, its cover plate should be tight.

3.6.9 the sub control rooms of class A and class B plants with explosion risk shall be set independently.

9.3.7 dry dust collector and filter for purifying explosive dust shall be arranged in an independent building outside the plant Inside the building, the fire prevention distance between the external wall of the building and the affiliated plant shall not be less than 10m.

9.1.6 combustible gas pipes and class A, B and C liquid pipes shall not pass through the ventilator room and ventilation pipe, and shall not be laid close to the outer wall of the ventilation pipe.

When they are set next to the outer wall, they shall be separated from other parts by fire partition with fire resistance limit of not less than 3.00h.

Its bearing structure should be reinforced concrete or steel frame and bent structure.

9.1.2 the air in class A and class B plants shall not be circulated Use.

9.2.4 the heating pipeline shall not pass through the room with gas, steam or dust that can cause combustion or explosion in contact with the heating pipeline.

3.6.12 Class A, class B and class C liquid warehouses shall be equipped with facilities to prevent liquid dispersion.

3.6.14 explosion proof measures and pressure relief facilities shall be taken according to the provisions of this section for warehouses with explosion risk or parts with explosion risk in the warehouse.

3.6.4 the pressure relief area of the power house should be calculated according to the following formula.

The mass of light roof slab and wall as pressure relief facilities shall not be greater than 60kg / m ²。 The pressure relief facilities on the roof shall take measures to prevent the accumulation of ice and snow.

9.2.3 the following plants shall be heated by non recycled hot air: 1.

3.6.7 class A and class B production parts with explosion risk should be arranged at the pressure relief facilities near the outer wall of single-layer plant or the top floor of multi-layer plant Near the pressure relief facilities near the outer wall.

three The trench should not be set in the plant.

9.1.3 the air supply equipment and exhaust equipment serving class A and class B plant shall be arranged in different ventilator rooms, and the exhaust equipment shall not be arranged in the same room as the air supply and exhaust equipment of other rooms In the ventilator room.

The ceiling should be as flat as possible without dead corners, and the upper space of the plant should be well ventilated.

When the fire damper is set at the place where the horizontal or vertical air supply pipe enters the production workshop, the horizontal or vertical air supply pipes of each floor can share an air supply system.