Source: thermal insulation decoration system in recent years, under the strong support of the state, urbanization and the development of the real estate industry, prefabricated buildings show a rapid development trend

.

According to the data of toubao Research Institute, the scale of prefabricated construction market increased from 40.4 billion yuan in 2014 to 442 billion yuan in 2018, with a compound annual growth rate of 81.9%, and it is expected to increase to 896.34 billion yuan by 2023

.

In addition, the new construction area increased from 114 million square meters in 2016 to 418 million square meters in 2019, accounting for 13.40% of the new construction area from 4.97%

.

According to the opinions on promoting the sustainable and healthy development of the construction industry issued by the state office, the proportion of prefabricated buildings in new buildings should reach 30% by 2025

.

It can be seen that prefabricated building has become the future development trend of China’s construction industry, and the development prospect is good

.

However, combined with the current situation, there are still some problems to be solved, which restrict the healthy development of the industry

.

Among them, one of the most prominent problems is: the current commonly used prefabricated exterior wall insulation method, in the actual application of prefabricated housing, there are still drawbacks

.

According to industry insiders, there are three ways of prefabricated building external wall insulation: directly using prefabricated sandwich external wall panel, prefabricated external wall + traditional external wall external insulation system, prefabricated external wall + internal insulation system

.

But these three kinds of insulation methods have their own shortcomings, which affect the quality of prefabricated buildings

.

Specifically, No.1 directly adopts prefabricated sandwich exterior wall panels, which is the common insulation method of prefabricated buildings

.

However, this kind of insulation method has poor insulation performance and is not friendly to the living environment

.

The structure of prefabricated sandwich thermal insulation exterior wall panel is composed of decorative outer leaf wall panel, load-bearing inner leaf wall panel and thermal insulation material through a large number of metal connectors

.

The existence of metal connectors will greatly reduce the thermal insulation performance of the wall

.

According to the test analysis, the metal connector in the prefabricated sandwich insulation exterior wall panel will reduce the insulation performance of the wall by at least 10% – 20%

.

Under the background of higher and higher requirements for building energy efficiency, such as Beijing recently officially issued a policy to increase the energy saving rate of residential energy consumption in Beijing from 75% to more than 80%, the energy saving gap of 10% – 20% can not be underestimated

.

Figure: structural drawing of prefabricated sandwich thermal insulation exterior wall panel: a large number of metal pull connectors in the prefabricated sandwich thermal insulation layer

.

At the same time, the existence of a large number of metal pull connectors is easy to cause cold and hot bridge phenomenon on the wall, and then cause condensation, mildew and even dripping in the house, which seriously affects the appearance of the wall and the health of the residents

.

Figure: Wall mildew phenomenon caused by cold and hot bridge effect ﹣ No.2 ﹣ prefabricated external wall + traditional external wall external insulation system ﹣ prefabricated external wall + traditional external wall external insulation system ﹣ insulation method, simple explanation is to do insulation separately after prefabricated external wall installation

.

Compared with the direct use of prefabricated sandwich insulation exterior wall panel, the insulation performance of this method is higher, but the disadvantage is that the insulation layer of this method is not integrated with the prefabricated exterior wall in the factory, which needs to be installed by hanging basket or climbing frame in the later stage, and after the installation of the insulation layer, the external wall decoration layer needs to be produced again, so the construction cycle is relatively long, and the prefabricated building parts are not fully utilized The advantages of integration and construction assembly

.

In addition, the traditional external wall external insulation system basically uses manual operation to complete the construction, there are many uncontrollable factors, the construction quality varies from person to person, and the construction quality can not be effectively guaranteed

.

Figure: construction drawing of traditional external wall external insulation system No.3 prefabricated external wall + internal insulation system “prefabricated external wall + internal insulation system” refers to adding insulation layer inside prefabricated external wall structure

.

Compared with the former two methods, this method is less applied

.

Because this method not only takes up the use area of residents, but also can’t bring advantages for developers in the competition of competing products

.

But also easy to affect the residents of the secondary decoration, resulting in indoor walls can not hang heavy

.

At the same time, the hanging and fixed objects of the interior wall are easy to damage the internal insulation structure, and then affect the thermal insulation performance of the building

.

Photo: see the practice of internal insulation system here, some friends may ask, is there no other better insulation method that can be used in prefabricated buildings? Fortunately, with the rapid development of science and technology, more and more new insulation materials appear in the construction market, and more insulation materials can be used in prefabricated buildings

.

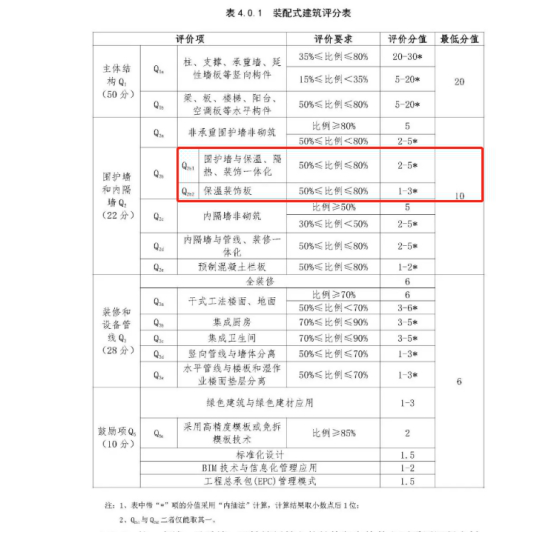

Among them, the advantages of precoated insulation and decoration integrated board with suit type building are obvious

.

Why do you say that? There are two reasons: first, the precoated insulation and decoration integrated board has high performance and high application value

.

As a new type of external thermal insulation system, the precoated thermal insulation and decoration integrated board has excellent thermal insulation performance

.

Different from the traditional exterior insulation system, the insulation layer in the precoated insulation and decoration integrated board is not directly pasted with the base wall with adhesive, but is processed and compounded on the calcium silicate board by the automatic production line

.

Precision machining makes the bonding between insulation layer and calcium silicate board more precise, reduces heat loss, and has better effect for building thermal insulation

.

At the same time, compared with the traditional external wall insulation system, the pre coated insulation and decoration integrated board rarely appears cold and hot bridge phenomenon

.

At present, the traditional external thermal insulation systems commonly used in our country mainly include curtain wall system and thin plastering system

.

Among them, the curtain wall system needs to rely on the keel to install the insulation layer, the thin plastering system needs a lot of insulation nails to fix the insulation layer, and the integrated board only needs to add anchors at the bottom to install the insulation layer

.

As we all know, the components with metal properties have high thermal conductivity, so the cold and hot bridge phenomenon of curtain wall system and thin plastering system with large area metal components is more serious, and the energy saving is poor

.

Figure: large area keel used in the installation of thermal insulation layer in curtain wall system figure: a large number of thermal insulation nails used in the installation of thermal insulation layer in thin plastering system figure: anchor used in the installation of thermal insulation layer in precoated thermal insulation and decoration integrated board in addition, precoated thermal insulation and decoration integrated board has strong weatherability, long finishing life and high application value as external wall material

.

In particular, the fluorocarbon pre coated insulation and decoration integrated board has strong weather resistance, corrosion resistance, pollution resistance and freeze-thaw resistance, which can well resist the erosion of natural factors such as ultraviolet, acid rain, dust and haze on the external wall

.

It is understood that the service life of high-quality fluorocarbon pre coated insulation decorative integrated board is up to 30 years, which is 3-5 times longer than that of traditional thin plastering system

.

Second, the product characteristics of precoated insulation and decoration integrated board fit the fundamental significance of the development of prefabricated buildings

.

First of all, the pre coated thermal insulation and decoration integrated board meets the development significance of prefabricated buildings to promote energy saving and environmental protection

.

As mentioned earlier, the precoated thermal insulation and decoration integrated board has high-quality thermal insulation performance, which can reduce the heat transfer between indoor and outdoor, keep the building warm in winter and cool in summer, and greatly reduce the energy consumption of heating and refrigeration

.

At the same time, the pre coated insulation and decoration integrated board adopts the factory prefabrication mode, and the waste water, waste gas and waste residue formed in the manufacturing process can be treated in the factory, thus eliminating the generation of construction waste from the source

.

In addition, the long-life performance of the insulation and decoration integrated board can greatly reduce the frequency of building washing, maintenance and renovation, greatly reduce the generation of construction waste, and protect the ecological environment

.

Secondly, the pre coated thermal insulation and decoration integrated board meets the development significance of prefabricated building to improve the construction efficiency

.

The pre coated heat preservation and decoration integrated board is the mechanical processing and manufacturing of subdivided “parts” in the factory, and the finished products can be directly transported to the site for installation

.

The production efficiency of the factory is much higher than that of manual operation, and the production and construction are not affected by bad weather and other natural environment, which greatly improves the construction efficiency

.

Compared with the traditional external wall external insulation system, the construction period can be shortened by at least half.

.