“Robot workers” in science fiction movies are becoming a reality

.

Can building a house be as automatic and mechanized as building a car? On March 4, the construction site of Fengtong garden project in Shunde, Foshan, Guangdong Province

.

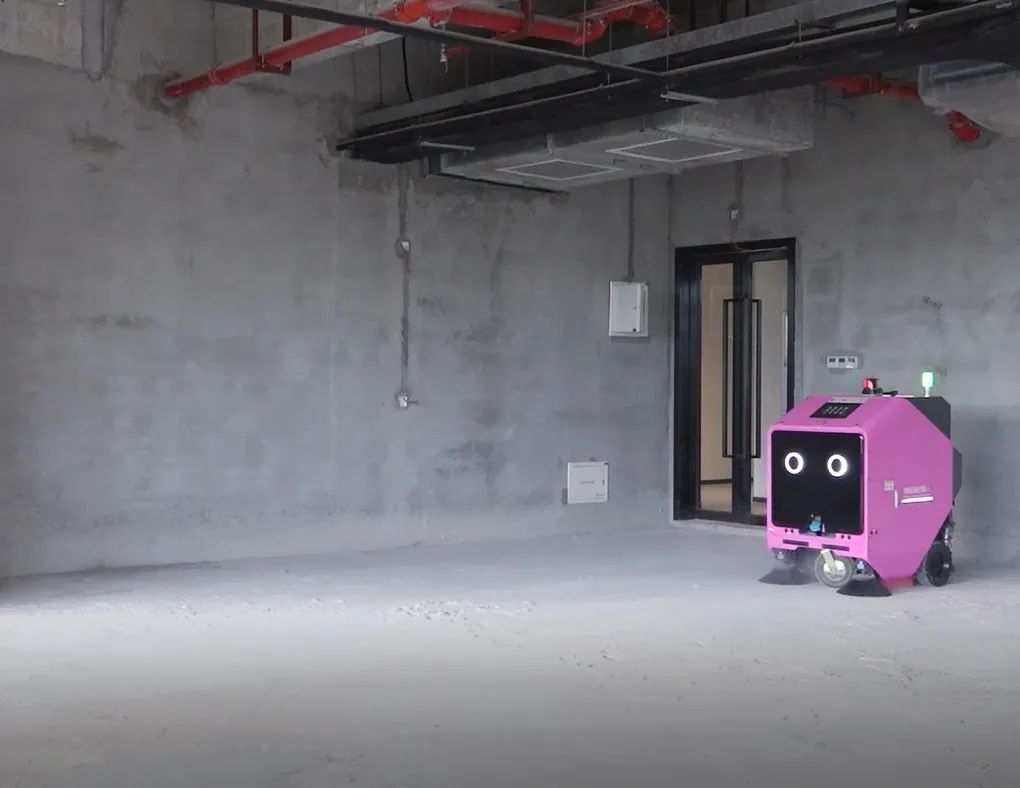

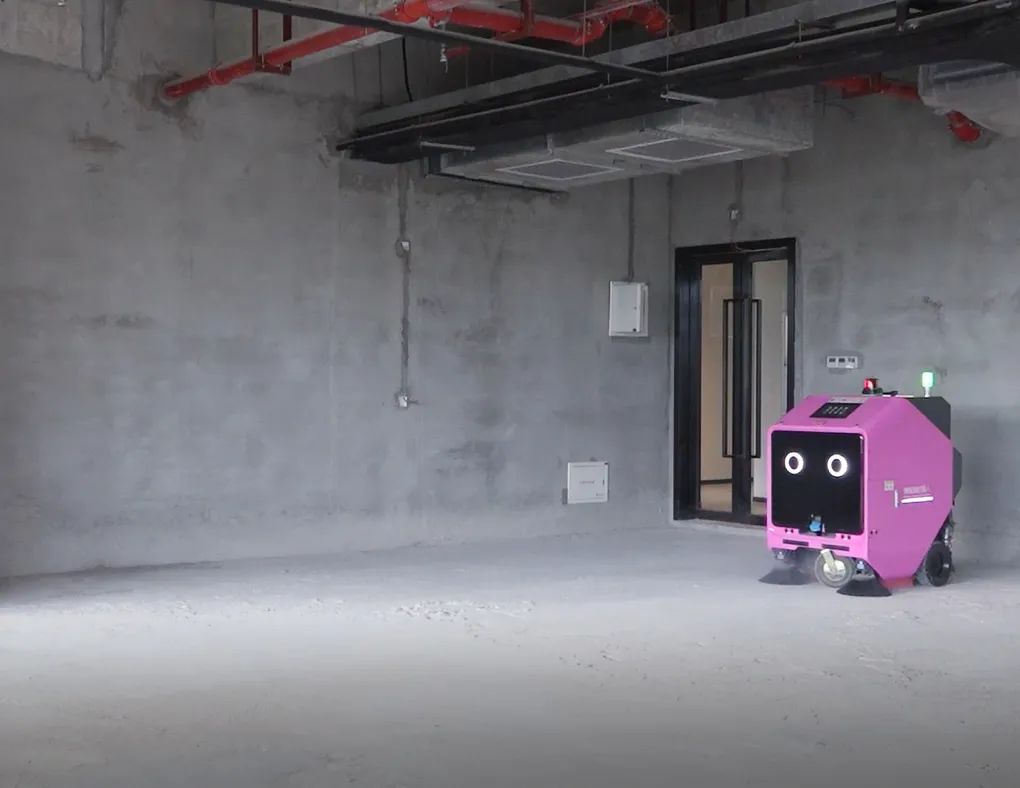

With two cute big eyes, the cleaning robot is cleaning stones and dust on the road

.

This robot can plan its own journey, and the ground they walk on can be cleaned as new as before

.

At the same time, on the working face of the underground garage, the “1.7-meter-tall” floor grinding robot is also busy

.

With the high-speed rotation of the grinding plate at the bottom, the rough ground is soon polished as smooth as a mirror, and the dust generated in the process is timely inhaled into the dust bag behind

.

If they encounter pillars or other obstacles, these robots can avoid them autonomously and flexibly

.

Fengtong garden project is the first commercial application project of construction robot of Guangdong bozhilin robot Co., Ltd

.

(hereinafter referred to as bozhilin company)

.

It is also the only pilot project in China to introduce construction robot and apply it in batch in the construction process

.

In this “intelligent” construction site, we can no longer see the scene of dust flying in the sky and not distinguishing the sun from the sky, nor can we find the disheveled and dirty construction workers

.

On the contrary, each robot “worker” with unique skills and good looks at the scene, from the plastering of the roof to the indoor spraying, from the floor grinding to the high-altitude construction of the outer wall, these different types of construction robots are performing their tasks in an orderly manner

.

“I didn’t expect What a shock People who visited the site couldn’t help but praise, “the era of building houses by robots has really come.” A few years ago, when Qu Qiang first walked into the construction site, he had a deep feeling about the “dangerous, complicated and dirty” of this work

.

When he climbed the four story scaffold, stepped on the steel bar and turned over the wooden formwork, he saw a dozen workers busy with tools

.

Their clothes, shoes and hats were full of splashing concrete mud spots “If my parents are doing such hard work here, what can I do for them?” Qu Qiang and his team members were filled with emotion

.

At present, China’s construction industry is indeed large but not excellent

.

Most enterprises still stay at the level of “moving bricks, binding steel bars, pouring concrete and installing formwork”

.

The overall application degree of advanced technology and engineering technology is low

.

On tens of thousands or even hundreds of thousands of construction sites across the country, “aging” construction workers are sweating in the dust flying production site, even high-risk operation

.

According to the data of the National Bureau of statistics, the average age of migrant workers in China in 2019 is 40.8 years old, which has increased by 0.6 years compared with 2018, and the proportion of those over 50 years old is more than 24%

.

China’s construction industry is in urgent need of a profound change, and whether from the efficiency, quality, safety or cost considerations, robots are a good choice

.

Qu Qiang and his team took the lead in such an attempt

.

As the director of bozhilin’s concrete product line, Qu Qiang’s main work is to lead the research and development of concrete construction robot

.

They regard the construction site as the first “laboratory”, stay at the concrete construction site day and night, take advantage of the construction gap to carry out continuous tests, implement the “three shifts” mechanism, and seize every minute to record data

.

Because the construction time is uncertain, sometimes the team members fall asleep at the construction site in the middle of the night

.

Sometimes when they are informed that there is a working face, the team members rush in to test immediately and work until dawn

.

Sometimes in broad daylight, the hydration reaction of concrete is as high as 40 degrees at the beginning, and every member’s clothes are soaked through

.

In order to avoid heatstroke, they simply drink antipyretic in advance and then go to battle After a long period of exposure to the sun and rain, as soon as Qu Qiang’s sleeves were pulled open, the whole arm was black and white, and everyone affectionately called him “the black doctor”

.

But even so, these more than 20 young people did not complain or flinch

.

From March 2019, Qu Qiang and his team members spent three months to improve the concrete robot

.

In the end, almost every functional module has been iterated and achieved remarkable results

.

It is worth mentioning that as of the end of February this year, bozhilin company has more than 4000 R & D personnel

.

These people, like Qu Qiang, the “black doctor”, are outstanding talents in civil engineering, robotics, artificial intelligence, digitization and other fields from well-known universities at home and abroad

.

Their average age is only 30.2 years old

.

Why should we study the construction robot? First, the construction robot can work 24 hours without rest, and the construction period will be greatly shortened

.

In this way, the construction efficiency will be greatly improved

.

Moreover, the construction robot can work under various conditions and is less affected by the environment

.

For example, in hot weather and other bad weather, construction robots can work as usual

.

Second, compared with manual and manual work, the accuracy of construction robot is higher

.

If we follow the preset program and model in advance, the probability of error of construction robot is much smaller than that of manual

.

Third, compared with construction workers, construction robots can successfully complete some difficult and dangerous work

.

Fourth, the aging of construction workers may not rule out the possibility of labor shortage in the future

.

This phenomenon exists in many countries

.

In the past, the age of the workers who joined the construction industry is gradually increasing, while the new young people are not willing to join the construction workers, which leads to the increasing employment gap

.

Will construction robots completely replace construction workers? So, construction robot has so many advantages, it will replace construction workers, will lead to construction workers unemployment? Some netizens think that in the future, this kind of possibility also exists

.

With the development of human science and technology, most fields will be intelligent, and so will the intelligent construction field

.

There are also netizens Tucao: if the construction robot instead of construction workers, even after moving bricks can not move, then make complaints about unemployment

.

At present, we don’t need this kind of situation

.

After all, today’s construction robots are not high-tech enough to replace human, and they are still in the research and development stage, so there is still a long way to go for machinery to replace human

.

Moreover, the cost of developing and using construction robots will be very expensive, which is also an important issue that we have to consider

.

Source: lookout think tank.

.