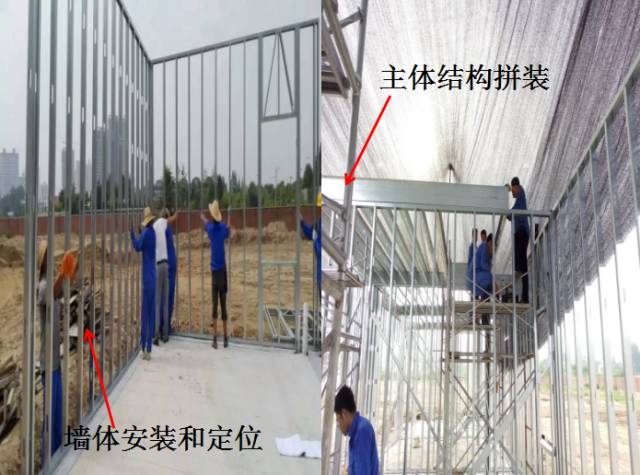

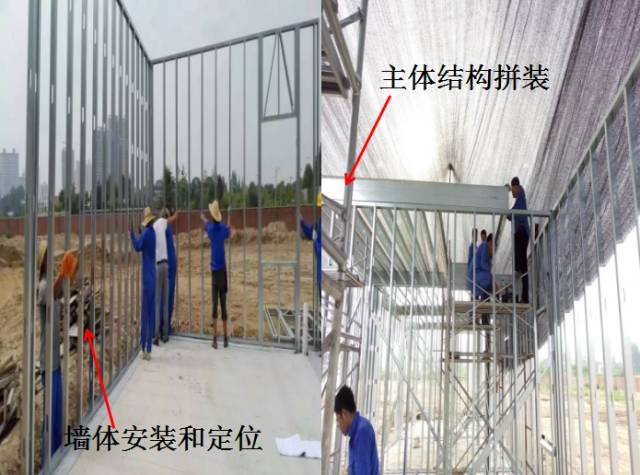

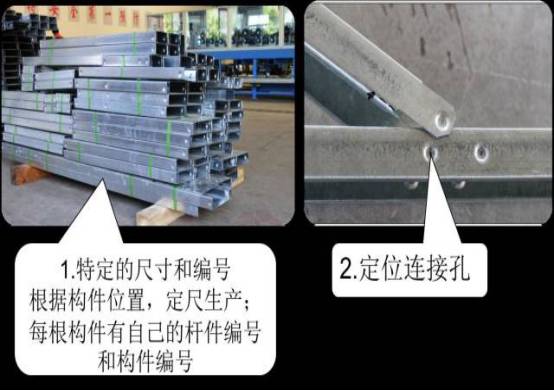

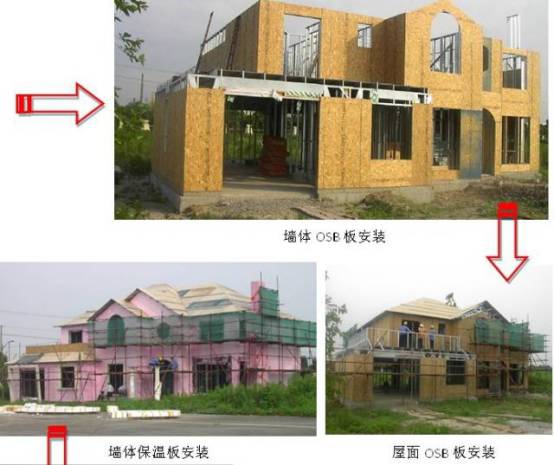

The ultra light steel building can also complete part of the assembly task in the factory according to the needs of the project, form the whole wall and floor, reduce the amount of on-site work, and speed up the on-site installation

.

From the inside to the outside, the building roofs are gypsum board, R30 centrifugal glass fiber cotton, light steel keel, OSB, waterproof membrane and roof decoration layer

.

According to the project calculation, the housing rate of light steel residential system is 5% – 10% higher than that of ordinary brick concrete structure

.

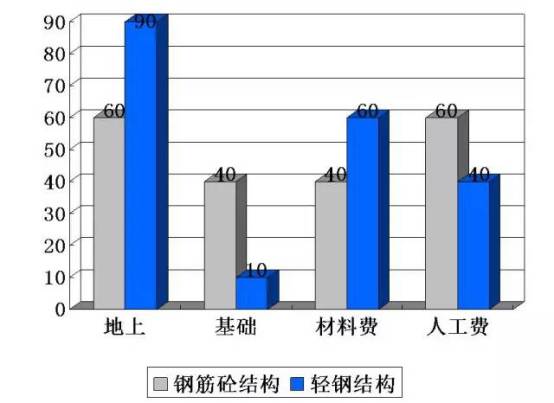

Compared with traditional buildings, the use area of the system is increased by 5-10%, which significantly reduces the foundation cost; the unique wall bearing system makes the building modeling light and flexible, and improves the flexibility of indoor layout; the low-carbon environmental protection building materials make the building more durable and safer, It is an efficient and energy-saving green building system with good seismic, fire, thermal and sound insulation performance

.

3、 The normative references mainly refer to the following standard clauses

.

The cornice sealing board is of porous structure, which makes the whole roof truss ventilated

.

The construction period of the blank room without foundation construction is 1-2 months, and the construction period of the hardbound repair room is 2-3 months

.

2、 Performance index: durability: more than 90 years of service life; snow resistance: 1.55kn/m2 of basic snow pressure; seismic performance: 9 degree fortification (basic seismic acceleration 0.4g); wind resistance: 0.85kn/m2 of basic wind pressure, 209km / HR wind speed; sound insulation performance: the sound insulation capacity of exterior wall (200 mm thick wall) is 65dB, and that of interior wall (double-sided double-layer 9.5mm gypsum board, 181mm wall) is 65dB The results show that: the sound volume is 44db; the ventilation performance: the combination of natural ventilation and air supply ensures that the indoor air is fresh and clean, and the fresh air volume is more than 15%; the impact resistance of external wall: 250kg concentrated impact load; the thermal insulation performance: the thermal resistance value of 200 mm thick wall is 4.24k? M2 / W, and its thermal insulation performance is twice that of 490mm thick porous block brick

.

It is convenient for construction in areas where transportation is inconvenient, such as islands and mountainous areas

.

4、 Seven advantages of light steel residential system █ safety compared with wood structure buildings, the fire resistance and termite resistance of steel structure buildings are much better than that of wood structure buildings

.

Because R19 centrifugal glass fiber cotton and 25 mm thick extruded board are used in the wall, the thermal resistance of the wall system can reach 4.24 kn ^ / W, and its thermal insulation performance is twice that of 490 mm thick porous block brick wall

.

█ the fast light steel residential system adopts factory processed components, field assembly and no maintenance, so the construction speed is 30% – 50% higher than that of ordinary brick concrete structure

.

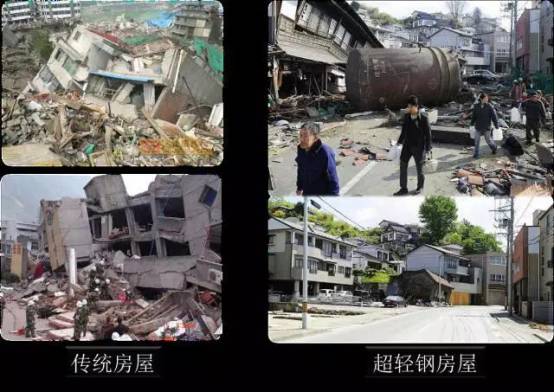

The damage of a single light steel keel or europine plate will not immediately lead to the damage of the whole structure, which is conducive to the escape of people in the building

.

█ the building materials used in the environmental protection light steel residential system products are all green environmental protection materials that meet the national standards

.

It is suitable for projects with poor local construction conditions and short construction period

.

The light steel keel can still be recycled after 70 years

.

█ the external wall of energy-saving light steel residential system adopts double-layer thermal insulation structure, which are gypsum board, light steel keel, R19 centrifugal glass fiber wool, OSB (europine board), breathing paper, extruded board and external wall facing layer from the inside to the outside

.

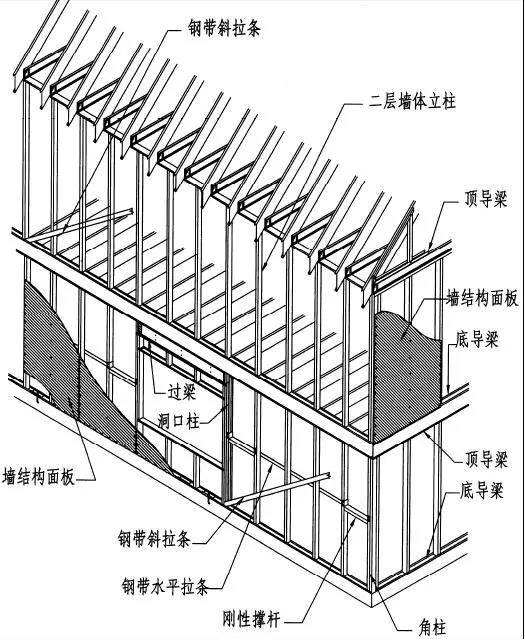

The wall and floor formed by the light steel keel and europine plate are the load-bearing structures

.

█ scope of application: the super light steel residential system is applicable to the newly-built, reconstructed and expanded buildings with 1-6 floors (excluding basement and cornice height no more than 12m)

.

█ convenient compared with the traditional brick concrete structure, the transportation volume of the steel structure building with light weight is less than that of the brick concrete structure

.

Compared with the brick concrete structure, the whole construction process greatly reduces the discharge of waste water, dust and solid waste, which is conducive to the development of the local environment Protection

.

The installation time of a 100 square meter ultra light steel main structure is only 4-5 days, and the overall construction period is at least 1 / 2 shorter than that of traditional buildings.

.

At the same time, due to the light steel structure system using wallboard and floor force rather than the traditional beam column force, so there are almost no beams and no columns in the light steel building, the space utilization is higher

.

The circulating air can not only prevent mildew, but also play the role of thermal insulation

.

The emergence and development of ultra light steel structure in North America is largely due to the poor fire resistance and termite resistance of wood structure, so the ultra light steel structure system is developed on the basis of light wood structure

.

When the standard is revised, the latest version of the reference standard will be used: load code for building structures (GB 5009-2012), code for design of concrete structures (GB 50010-2010), code for seismic design of buildings (gbsooll-2010), code for fire protection design of buildings (GB 50016-2014), code for design of steel structures (GB 50017-2003), cold-formed thin-walled steel structures (GB 50016-2014) Code for design of steel structures (GB 50018-2002) unified standard for reliability design of building structures (GB 50068-2001) technical specification for low rise cold formed thin walled steel buildings (jgj227-2011) cement fiber flat (JC / t412.1-2006) fiber reinforced calcium silicate board (JC / t564.1-2008) code for acceptance of construction quality of steel structures (GB 5005-2001) carbon structural steel (GB / t700-2006) cold formed steel technology Technical conditions (gb6725-2008) low alloy high strength structural steel (GB / t1591-2008) standard for quality inspection and evaluation of steel structure engineering (GB 50221-2001) current relevant professional technical specifications and regulations of other countries or industries

.

The whole construction process is divided into eight steps: foundation construction, wall installation, roof installation, structural sealing board, external wall insulation, interior decoration, outdoor decoration and delivery

.

It belongs to the statically indeterminate structure system

.

Overview █ basic features: a house building system with cold-formed thin-walled steel members as the basic structural framework, new structural plates as the structural system, and other thermal insulation and decoration materials through factory integrated production and field assembly

.

At the same time, the steel structure building with light weight is more conducive to resist the horizontal load (the horizontal load is the product of the building weight and the horizontal acceleration, and the smaller the weight of the building is, the smaller the horizontal load is)

.

█ the thickness of the double-layer thermal insulation decoration exterior wall of the practical light steel residential system is only 180mm, which is 60mm smaller than that of the brick concrete structure wall (generally 240mm) without thermal insulation decoration

.

In the construction process of light steel residential system, the material loss is reduced by 60%, the on-site waste is reduced by 80%, the recyclable materials account for 80%, and the building energy saving is increased by 50%

.

The thermal resistance value of the whole roof system is 5.284kn ^ / W, which is 75 times of that of ordinary 120mm thick concrete roof (thermal resistance value is 0.07kn ^ / W)

.

The system adopts cold-formed thin-walled steel structure system, which has the characteristics of small section size and light weight

.

The demand for construction water is small

.

Compared with the traditional brick concrete structure, the steel structure system itself is more malleable and elastic than the brick concrete structure

.

The ultra light steel structure belongs to the plate rib structure system

.

Therefore, in the earthquake prone areas of Japan and Taiwan, low rise buildings are mostly light-weight wood structure and steel structure buildings

.

However, the number of floors of cold-formed thin-walled steel frame, steel structure and reinforced concrete structure is not limited

.

In the process of on-site construction, a large number of finished components are used for installation

.

Summary of the advantages and construction steps of light steel structure prefabricated building █ 1

.