Jianjiantong media ID: jianzhong001 construction operation standard of socket type steel pipe scaffold with turnbuckle socket type steel pipe scaffold safety inspection standard socket type steel pipe scaffold with turnbuckle is a new type of straight plug steel pipe scaffold with self-locking engineering

.

Compared with the traditional fastener type cantilever frame, it has obvious advantages in the aspects of erection efficiency, reliability, safety, cost saving, energy saving and environmental protection Improve

.

1、 The inspection and evaluation of socket type steel pipe scaffold should comply with the current industry standard “safety technical code for socket type steel pipe scaffold in building construction” jgj231

.

(the pictures in this paper are from the Internet, and the copyright belongs to the original author)

.

2

.

The inspection and evaluation guarantee items of socket type steel pipe scaffold include: construction scheme, scaffold foundation, scaffold stability, rod setting, scaffold board, disclosure and acceptance

.

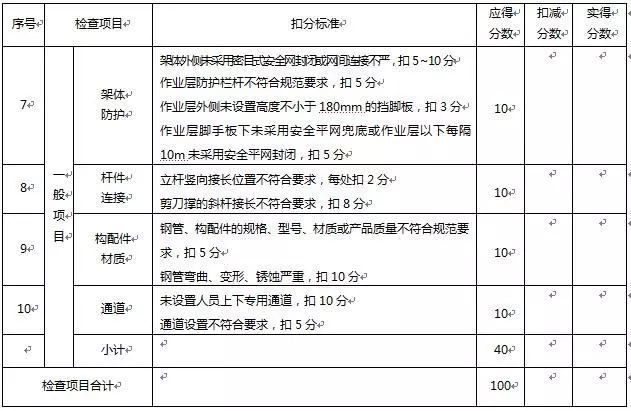

General items include: frame protection, rod connection, material of components and fittings, passage

.

The erection height of socket type steel pipe scaffold should not be more than 24m

.

3、 The inspection and evaluation of the guarantee project of the socket type steel pipe scaffold shall comply with the following provisions: (1) the construction scheme shall be prepared for the erection of the scaffold body, and the structural design shall be calculated; the special construction scheme shall be reviewed and approved according to the provisions

.

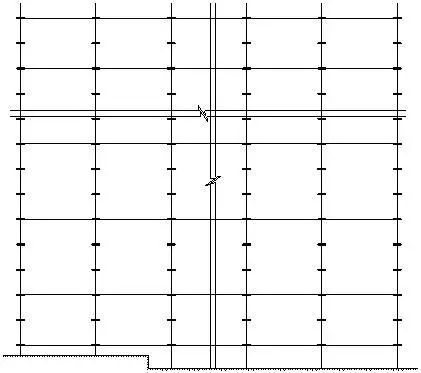

Draw the plan, elevation and section (2) of the overall layout of the frame structure

.

The vertical pole foundation shall be leveled and compacted according to the scheme requirements, and drainage measures shall be taken

.

The base plate and adjustable base must be set at the bottom of the vertical pole on the soil foundation, which shall meet the specification requirements

.

The vertical and horizontal sweeping poles of the frame shall meet the specification requirements

.

The adjustable base should be set at the bottom of the vertical pole, and the base plate can also be set at the bottom of the vertical pole

.

The length of the base plate should not be less than 2 spans

.

When the height difference of foundation is large, the adjustable base can be used to adjust the vertical pole, so that the connecting plate of the same horizontal pole installed on the adjacent vertical pole is in the same horizontal plane

.

(3) The frame body shall be stable, the connection between the frame body and the building structure shall meet the requirements of the specification, and the wall connecting parts shall be set from the first step of the horizontal bar at the bottom of the frame body, and other reliable measures shall be taken to fix it when it is difficult to set there; the frame body pull-out joint shall be firm and reliable; the wall connecting parts shall adopt rigid bars; the setting of the vertical diagonal bar and cross bracing of the frame body shall meet the requirements of the specification; the vertical diagonal bar shall meet the requirements of the specification Both ends of the scaffold shall be fixed at the joint of the vertical and horizontal horizontal bars and the vertical bar; the diagonal bar and cross bracing shall be set continuously along the height of the scaffold, and the angle shall meet the specification requirements

.

Along the longitudinal direction of the outside of the frame, a vertical diagonal bar shall be set for each layer of every 5 spans or fasteners shall be set between every 5 spans, and a vertical diagonal bar shall be set for each transverse layer of the end span of steel pipe cross bracing

.

The two ends of the vertical inclined bar shall be fixed at the joint of the vertical horizontal bar and the vertical bar

.

(4) The distance between poles and the step distance of horizontal poles should meet the design and specification requirements; the vertical and horizontal horizontal poles should be set at the connecting plate of poles according to the step distance designed in the special construction scheme; when the horizontal pole layer of double row scaffold is not equipped with buckle type steel scaffold board, the horizontal inclined pole should be set according to the specification requirements

.

The outer surface of the coil bolt shall be consistent with the inner surface of the horizontal rod and the inclined rod end

.

Use a hammer of not less than 0.5kg to tighten the bolt to ensure that the exposed end of the bolt is not less than 15mm

.

When there is no buckle type steel scaffold board on the working floor, the horizontal diagonal bar shall be set according to the specification requirements

.

(5) The material and specification of scaffold board shall meet the specification requirements; the scaffold board shall be laid tightly, smoothly and firmly; the buckle of the buckle type steel scaffold board must be completely hung on the horizontal bar, and the hook shall be locked

.

The external side of scaffold board frame of operation layer shall be provided with toe board and protective railing, and dense mesh safety net shall be hung on the external facade of scaffold

.

(6) The safety technical disclosure shall be carried out before the disclosure and acceptance of scaffold erection, and the written records shall be kept; when the scaffold is erected and used in sections, the acceptance shall be carried out in sections; after the erection, the acceptance procedures shall be handled, and the acceptance shall have quantitative contents and be signed by the responsible person for confirmation

.

4、 The inspection and evaluation of general items of plug-in coil type steel pipe scaffold shall meet the following requirements: (1) the outer side of the scaffold body shall be closed with dense mesh safety net, and the connection between nets shall be tight; the protective railings shall be set on the operation layer according to the specification requirements; the toe board with a height of not less than 180mm shall be set on the outer side of the operation layer; the bottom of the scaffold board on the operation layer shall be covered with safety flat net, Safety flat net shall be used for sealing every 10m below

.

(2) The lengthening position of the connecting rod should meet the requirements of the specification; the lengthening of the cross bracing should meet the requirements of the specification

.

Cast steel casing or seamless steel tube casing can be used for connecting the vertical pole

.

The length and insertable length of the connecting sleeve of the vertical rod in the form of cast steel sleeve shall not be less than 90mm and 75mm respectively; the length and insertable length of the connecting sleeve of the vertical rod in the form of seamless steel pipe sleeve shall not be less than 160mm and 110mm respectively

.

The clearance between the inner diameter of the casing and the outer diameter of the steel pipe of the vertical pole shall not be greater than 2mm

.

The connection sleeve between the vertical pole and the vertical pole shall be provided with the anti pulling pin hole for fixing the vertical pole connector, and the diameter of the pin hole shall not be greater than 14mm

.

(3) The specification, model and material of frame parts shall meet the specification requirements; the steel pipe shall be free from serious bending, deformation and corrosion

.

(4) The passage frame shall be provided with a special passage for personnel to go up and down; the setting of the special passage shall meet the requirements of the specification

.

(source: integrated in the network, the pictures and copyright belong to the original author, if there is any infringement, please contact to delete it!) Long press QR code to follow us ▶▶▶。

.