The successful construction of the super high-rise inclined wall structure in this project marks the smooth progress of the landmark project of the highest twin tower super high-rise under construction in Shanghai.

The two towers are like a gateway to the world.

Global entrepreneurs are welcome to Zhangjiang to build a world-class science city.

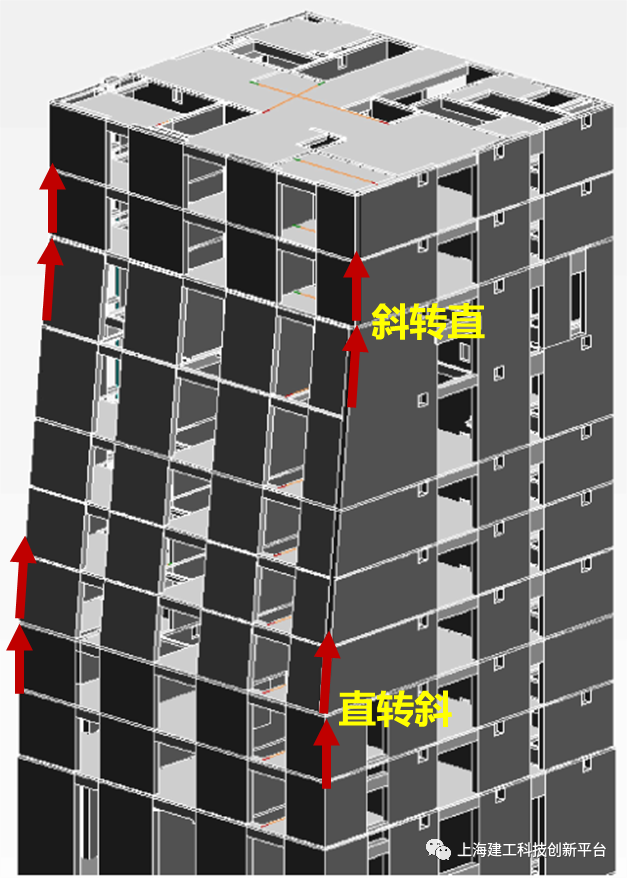

Rendering of Zhangjiang “Science Gate” East Tower Project Zhangjiang Science Gate East Tower Project The shear wall on the south side of the 45th to 49th floors of the core tube of the office tower of Zhangjiang Science Gate East Tower Project receives and divides inwards, 2.85m in total within the elevation range of 221.400-246.900 (total height 25.5m), forming an ultra-high inclined shear wall structure with an inclination of 6.37 °.

Adjacent to the Chuanyang River, they are two super high-rise towers with the same height and elevation.

At present, the construction of the core tube inclined wall section has been successfully completed, and has achieved good image effect.

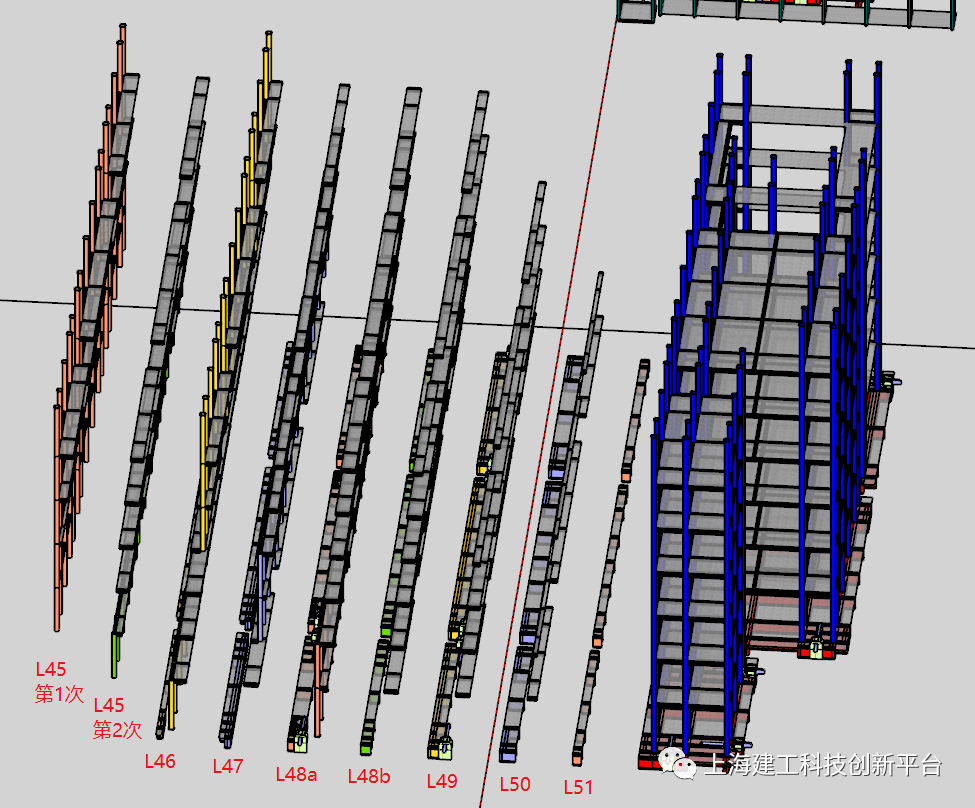

Layer by layer deformation adjustment scheme of integral steel platform based on BIM model dynamic construction simulation Part 2 Construction technology of super high-rise core tube inclined wall structure The construction of inclined wall section structure includes inclined reinforced concrete shear wall and inclined coupling beam.

Previously, relevant reports have been made on the structural design and construction progress (click the title to view the details): architectural structure The “gate of science” on the banks of the Chuanyang River — the twin towers in Zhangjiang, Shanghai architectural structure 37 hours 20000 cubic meters! The highest twin tower building under construction in Shanghai, Zhangjiang East Tower of “Science Gate”, was successfully completed.

(Click here to view) Zhangjiang Twin Towers in Shanghai are landmark buildings in the core area of Zhangjiang Science City in Shanghai.

The project team implemented the requirements for fully enclosed safety protection, established the finite element model of the equipment structure under various working conditions, and comprehensively reviewed the safety status of the overall steel platform; The BIM technology is used for collision detection, and multiple collision positions of components are found and disposed in advance; Based on a large number of construction exercises, carry out a comprehensive mapping of risk sources, find out the risk sources near the corner of the external scaffold and develop a closure plan in advance.

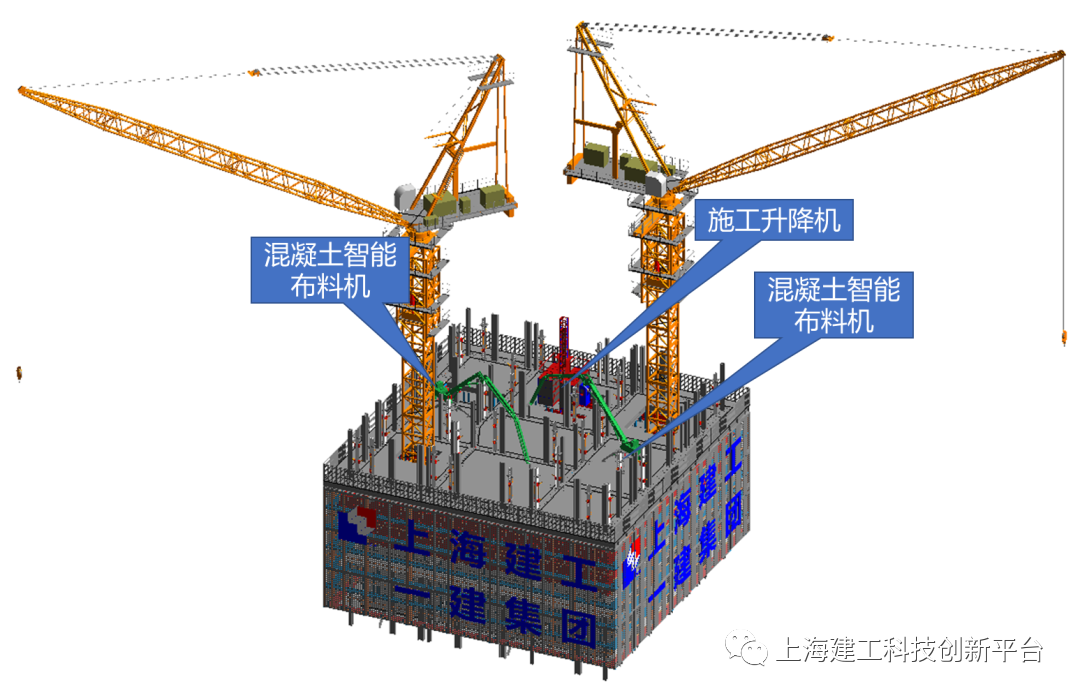

Model Diagram of Core Tube Inclined Wall Section of Steel Column Tube Frame Alternating Support Integrated Steel Platform Formwork System Zhangjiang Science Gate East Tower Project Core Tube Inclined Wall Structure Construction has posed new challenges to the overall steel platform equipment, inclined wall formwork support system and construction technology, and the whole process safety protection technology.

The project applies the steel column tube frame alternate supporting integral steel platform formwork system to the construction of the core tube shear wall structure, The large volume super high inclined wall structure poses a new challenge to the overall steel platform equipment and construction technology.

Based on the BIM model of the equipment structure, a large number of dynamic construction simulations are carried out.

The project gives full play to the core technical capabilities in the field of super high-rise construction equipment system and safety protection technology, and makes progress in the field of complex super tall structure construction with integrated application of information technology.

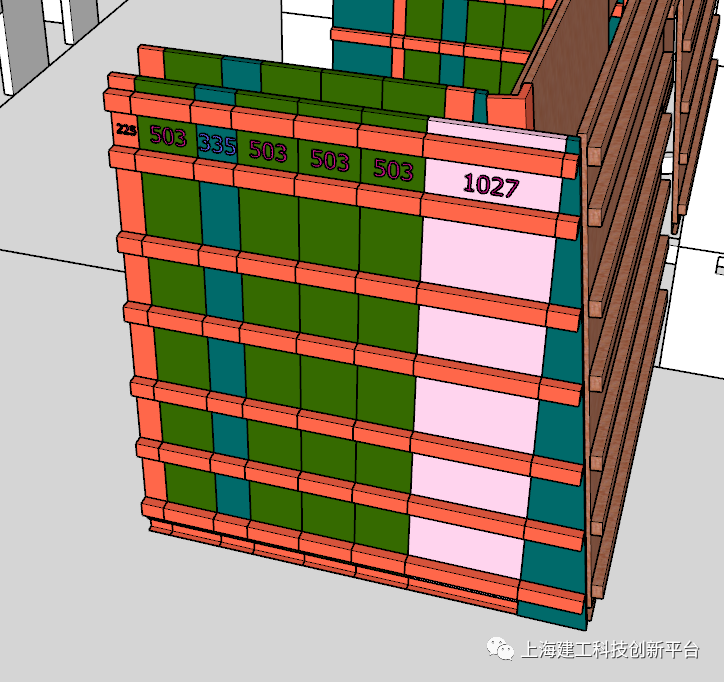

Integrated steel platform equipment, structure, finite element model, equipment collision detection, edge hazard source modeling, Part4, real-time pressure monitoring technology project department of inclined wall steel large formwork, carried out in-depth cooperation with the Group Research Institute, relying on the group’s key topic “Research on intelligent integrated steel platform formwork and support device technology suitable for core tube inclined wall”, and aimed at the construction problems of inclined wall structure concrete formwork, The research group developed the real-time monitoring technology for the internal pressure of the inclined wall steel large formwork, which realized the real-time monitoring, evaluation and early warning of the lateral pressure of the cast-in-place concrete formwork, reduced the construction risk of the inclined concrete formwork, and provided a strong support for the assurance of the molding quality of the inclined wall concrete structure..

Aerial photo of inclined wall structure Part 3 Safety protection technology for fully enclosed construction Part 3 The deformation adjustment of the overall steel platform equipment and the construction process of the inclined wall structure alternate with each other.

The completion of the project will help Zhangjiang Science City to become a national science center, a source of emerging economic growth in the Yangtze River Delta, and a Shanghai science and technology innovation center.

It is a symbol and symbol of Zhangjiang facing the world and welcoming global entrepreneurs to build a world-class science city in Zhangjiang.

Zhangjiang “Science Gate” East Tower Project is located in the core area of Shanghai Zhangjiang Science City and Zhangjiang City Sub center, with a total floor area of about 320000 square meters, including a 59 storey, 320 meter high office tower, a 25 storey, 100 meter high hotel tower, a 4-storey commercial building and a 3-storey cultural center, and a 4-storey basement as a whole.

Profile steel support is used as the supporting system of inclined shear wall steel formwork, The internal cantilevered bent is set as the formwork support system of the inclined coupling beam, which ensures the stability of the formwork system under the pouring and tamping conditions of the inclined wall concrete, effectively controls the deformation of the inclined wall structure, and fully guarantees the construction quality.

During the construction process, the structural deformation adjustment of the external hanging scaffold, internal tube frame and bottom beam of the integral steel platform is accurately controlled, and the lifting column The accurate displacement scheme of the steel corbel layer by layer ensures the stable and safe climbing of the overall steel platform and provides a solid foundation for the construction of the inclined wall structure.

Part 1 Deformation adjustment technology of integral steel platform for inclined wall construction During the layer by layer construction of the core tube inclined wall structure, the integral steel platform equipment structure adapts to the development of the inclined wall and deforms layer by layer.

The Project Department has carried out technical research on the main construction difficulties, developed a more detailed construction plan by using information technology, and carried out comprehensive technical support and process control during the construction process.

Based on BIM construction deduction, a form of steel formwork with strip drawing and formwork matching is proposed to adapt to the deformation conditions of inclined wall.

On October 24, the core tube structure of the office tower of Plot 58-01 (East Tower of Science Gate) in Zhangjiang Central District was successfully capped.

It is a super high-rise project that combines various high-end business forms such as office, hotel, commerce, and culture.

With the help of several safety protection measures, the safe and stable construction of inclined wall structure is ensured.