The down lead in the valve base must be connected with the reinforcement at the valve base.

(source: integrated on the Internet, the picture and copyright belong to the original author.

The installation height of lightning strip is parapet + 150mm, the straight-line spacing of fixed support card is 1m, and one is 0.5m at the turning center.

3、 The residential power supply system for equipotential and equipotential construction adopts TT, TN-C-S or TN-S grounding system, and carries out general equipotential bonding; Local equipotential bonding shall be made in the toilet.

Red lead antirust paint is applied twice, and finally silver powder paint is applied uniformly.

The overlapping welding length of the roof lightning protection network is L = 6D, which shall be welded on both sides.

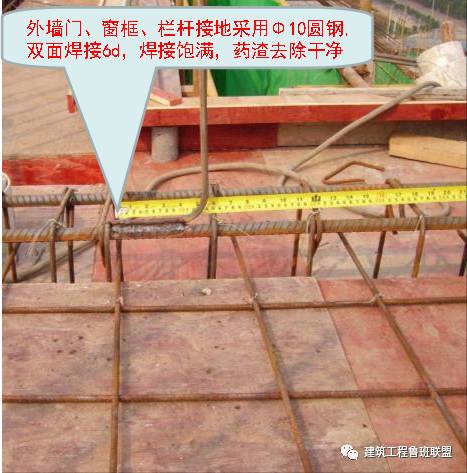

At least one ≥ Φ 10 reinforcement, used for the grounding of exterior wall doors, window frames and railings.

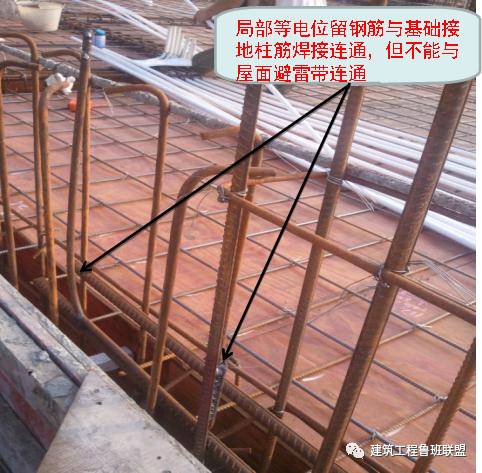

The horizontal grounding electrode for valve base grounding electrode construction is composed of the reinforcement mesh on the upper part of the valve plate foundation, and the column reinforcement is used as the vertical grounding electrode.

2.

Four steel bars are welded Φ 14) the reinforcement shall be used as the down lead, and the diameter shall not be less than 12mm).

There are two local equipotential methods: 1.

The down lead shall be kept away from the place easily accessible to people.

Except for special requirements in the design, the section of galvanized flat steel shall not be less than 48mm, and the diameter of galvanized round steel shall not be less than 10mm.

4、 The grading ring / outer door and window railing grounding grading ring and door and window grounding construction are to prevent side lightning.

The welding shall be straight, the support height shall be consistent, the paint shall be painted bright and free of sags.

3、 All metal components protruding from the roof and exterior wall shall be welded and connected with the lightning protection belt.

The recommended bending angle is 120 °).

5、 Installation of roof lightning arrester / lightning strip lightning arrester / lightning strip I.

Weld the pre equipotential reserved reinforcement with the Foundation Grounding column reinforcement, but not with the roof lightning strip (according to the requirements of the local Lightning Protection Office).

For the construction of single foundation grounding electrode, the horizontal grounding electrode is 40 * 4 galvanized flat steel, the column reinforcement is used as the vertical grounding electrode (the discharge reinforcement needs to be reliably welded with the bottom plate reinforcement), and the bottom plate reinforcement is used as the discharge electrode.

The welding method is overlapping welding, and horizontal welding is strictly prohibited.

4 * 25 flat steel is reserved in the equipotential box.

Round steel shall be used for welding connection between columns and beams, beams and beams, columns and retaining wall ground beams, and double-sided welding must be used for welding to ensure the reliability and safety of total equipotential connection.

When the pressure welding is adopted for the connection of the main reinforcement, the jumper wire and other welding treatment may not be welded at the joint).

It is welded to the top layer in series with the reinforcement layer by layer, and the down lead galvanized flat steel 40 with a certain length of the roof is welded × 4 or Φ 12 galvanized round steel.

All flat steel joints shall be overlapped with round steel, and each column shall be led with 2 pieces to reliably connect with flat steel.

If there is any infringement, please contact to delete!) long press the QR code to follow us ▶▶▶。.

2、 The concealed lightning protection belt shall be installed after the construction of civil roof capping and casting, and shall be laid at the position of no more than 20mm at the outer edge of capping, and the laying thickness shall not be more than 20mm; The vertical height of the welding lightning rod at the external corner is 300mm and perpendicular to the coping (according to the requirements of the local Lightning Protection Office).

The exposed down lead shall be sleeved with protective pipe 2m above the ground, clamped and painted with red and white paint.

According to the requirements of architectural design and lightning protection office, when the height exceeds the rolling ball radius, a grading ring shall be set every 6m (every other layer).

The grading ring can be welded into a closed ring by using two main reinforcements in the ring beam, which must be connected with all down conductors.

Trapezoid Rubber Magnetic Chamfer

The total equipotential shall be reliably connected with the grounding grid.

surface mounted roof lightning protection network shall be inserted after the roof capping construction of civil engineering, and shall be laid at the position not greater than 100mm at the outer edge of the capping; For surface mounted lightning protection belt, first hit the support with an electric hammer, then lay the lightning protection belt according to the design material, and reliably connect it with the down lead; The installation height of lightning strip is parapet + 150mm, the straight-line spacing of fixed support card is 1m, and the turning center is 0.5m, and red lead antirust paint is applied twice, and finally silver powder paint is applied uniformly; The lightning rod shall be welded at the external corner, and the erection height shall be 300mm, which shall be perpendicular to the coping (according to the requirements of the local Lightning Protection Office).

2、 Down lead construction 1.

Locate the down lead position according to the position marked in the drawing, and 2 down leads shall be used, not less than Φ 16 reinforcement (if there is no main reinforcement in the column) Φ 16.

(the cold lap joint of the main reinforcement must be welded, and the wire connection must be jumper welded.

During the construction of grounding electrode, the reinforcement in the pile and the reinforcement of ground beam shall be overlapped with round steel not less than ∮ 10, and double-sided welding shall be adopted, with the weld length ≥ 6D and single-sided welding length ≥ 12D.

The distance between down conductors shall be set according to the design requirements.

Building communication media ID: jianzhong001 I.

Foundation Grounding pile foundation grounding electrode construction, the horizontal grounding electrode is composed of the main reinforcement of the ground beam, and the vertical grounding electrode is composed of 2 reinforcements in each pile.

(the bending position shall not be less than 90 degrees and shall not be bent into a dead angle.

The resistance between metal pipes and other metal bodies within the scope of equipotential bonding and the terminal strip in the equipotential bonding box shall not be greater than 1 Ω.

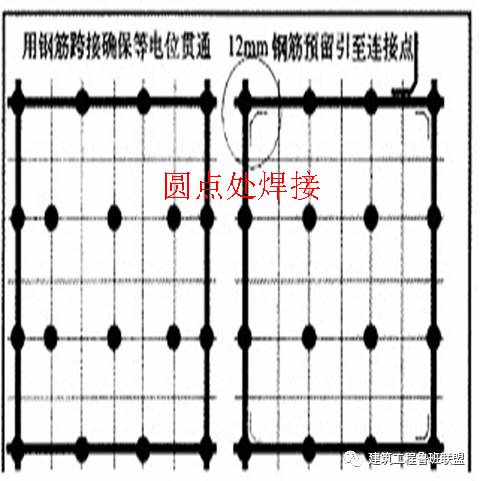

As shown in the schematic diagram, spot weld the joint of the reinforcement of the toilet bottom plate; 2.

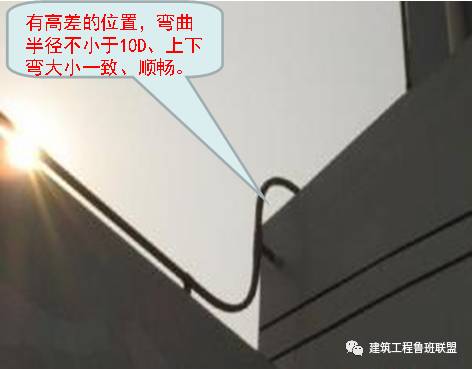

(when the ground beam reinforcement adopts threaded connection, the threaded connection must be connected with Φ 10) the bending radius of round steel (for cross welding) reinforcement shall not be less than 10d and 6D under special circumstances.

When constructing the horizontal reinforcement mesh of valve plate foundation, the horizontal reinforcement shall be directly welded and connected, and the welding length shall be greater than 140mm.

The down lead shall be connected with the ground beam reinforcement and column reinforcement with a diameter of not less than 12mm Φ 12 round steel shall be overlapped, the weld length of double-sided welding shall be 6D longer than the diameter of round steel, and the bending radius of round steel shall be 6D larger than the diameter of round steel, and shall be marked with paint (convenient for search).