Introduction with the continuous development of the construction industry and the continuous increase of people’s demand for architectural design, China’s construction industry has entered a new period of “industrial revolution”.

Zheng jiaochao [4] analyzed the one-way prestressed bearing capacity and two-way prestressed stiffness of the laminated plate respectively, studied the elastic design method of the two-way laminated plate, proved the rationality of the elastic design method of the two-way floor of the laminated plate through the reasoning equation, and designed and checked the stress of the prefabricated components of the laminated plate, By analyzing the component design of inverted T-shaped Prestressed two-way composite slab, this paper puts forward various parameters of prefabricated components and the rationality of reinforcement.

Through the implementation of various connection modes in the actual project, such as the connection between double-T slab and composite beam, the connection between prefabricated primary and secondary beams, and the connection between composite floor slab and composite beam, the objectives of shortening the construction period and improving the economy are achieved..

Ye Haowen and other [7] teams studied the standardized design, fully assembled structural system and connection node design conducive to efficient assembly, and put forward the key “three integration” assembled architectural design method.

Lu Jiasen [3] systematically summarized the design method of precast concrete frame structure, carried out the overall calculation and analysis of the structure through the selection of calculation parameters, expounded the design method of precast columns, composite beams and reinforced truss composite floors, and made a detailed analysis through the actual project, which provides a useful reference for the project.

The split components shall not affect the use function of architectural design.

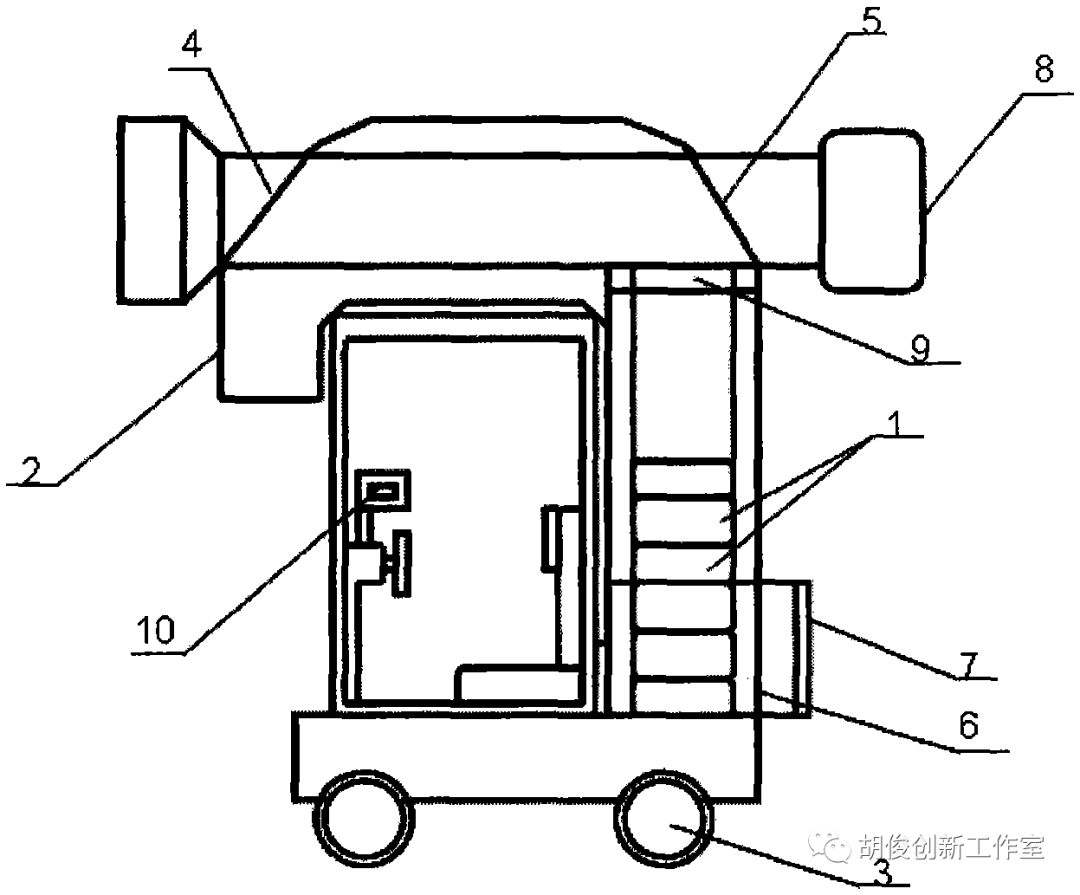

Fixing Socket Angular End Nail Plate

Expounded a variety of aboveground fabricated structural joint connections, and introduced that the on-site direct pouring concrete joint connection and prestressed fastening bolt burst joint connection adopt the tenon connection mode, and the connection method adopts the tensioning method, which overcomes the disadvantages of poor stress reliability of fabricated structural joints.

The new splitting method avoids the key problems existing in the first two splitting methods, such as the edge member stirrup bearing horizontal shear, the prefabricated wallboard becoming a vertical force transfer member, and the unclear overall force transfer path of the structure.

The splitting shall meet the construction requirements, and the types of split components shall be as few as possible.

The outer wall is basically fully prefabricated, and the inner wall can be partially prefabricated or completely cast-in-situ.

The traditional design method of prefabricated structure the change of prefabricated architectural design from cast-in-situ to the structural form of joint cooperation between cast-in-situ and assembly, and from general technology and system to proprietary technology and process, is a cross industry joint development process.

However, due to the misunderstanding of prefabricated architectural design, the development process of architectural industrialization is slow.

1.

This splitting is an innovation based on the splitting method of column beam system.

Zhong Chunling [8] et al.

(3) The connection node design of components the design of fabricated structure is realized through the reliable connection of nodes.

[8] adopted the prefabricated prestressed double-T plate technology, put forward six different connection and combination schemes of prefabricated components, and introduced the role of prefabricated design method in future buildings.

Its design methods mainly include the design of structural members, the splitting design of prefabricated members, the design of connecting nodes of members, and the design of finite element analysis.

(2) After the completion of structural calculation and component design of prefabricated components, the components need to be split and designed.

Different structures have different connection modes.

0.

Li Hongwang [6] introduced two splitting schemes of fabricated shear wall structure, in which all edge components are cast-in-situ, “prefabrication of non edge components and partial cast-in-situ of edge components, and connection of horizontal reinforcement ring dowel bars”.

(1) The design of structural members is based on structural calculation and analysis, and then the members are designed according to the analysis results.

By comparing the two existing splitting methods, he proposed a new splitting method of shear wall structure – basically full prefabrication of the outer wall, and the cast-in-situ part is set on the inner wall.

Fabricated structure refers to the structure assembled by prefabricated components through reliable connection on the construction site [1].

Design method is an important content to realize prefabricated building.

Lu Jianrong et al.

The principles to be followed in the design method should not only meet the use requirements of fabricated structures, but also follow the design principles of “integration”, “standardization”, “modularization” and “generalization”, and improve the construction efficiency by means of “less specifications and more combinations”.

This paper summarizes the traditional design methods of structural design, split design and node connection design in fabricated structure, and introduces the design method of fabricated structure based on BIM from three aspects: parametric design method, split design method and Revit secondary development design method, This paper puts forward many problems existing in the current industry operation of prefabricated building design methods, in order to promote the development of prefabricated buildings.

Based on the structural performance, the traditional assembly design method divides the structure into two parts: prefabricated components and connecting nodes, and divides the construction design into two parts: the production and assembly of prefabricated components.

Wang Xiaoshan [5] explained the split design of prefabricated structure through specific cases and on the basis of introducing the equivalent cast-in-place structure, showing the split of shear wall and beam, floor slab and staircase and balcony, and pointed out that there is no unified standard and principle for the split design method in the industry The design methods of component deepening design and creating prefabricated component library explore the design method of fabricated structure.

Assembly design method is a process in which architecture, structure and equipment participate in the design of assembly structure, and finally the designers deepen the design.

As we all know, the assembly type is the representative of building industrialization, which can effectively reduce the construction cost.

Abstract: as the future development direction of construction industry, prefabricated building is one of the most effective methods to realize construction industrialization, which is conducive to improve production efficiency.

Reduce costs [2].