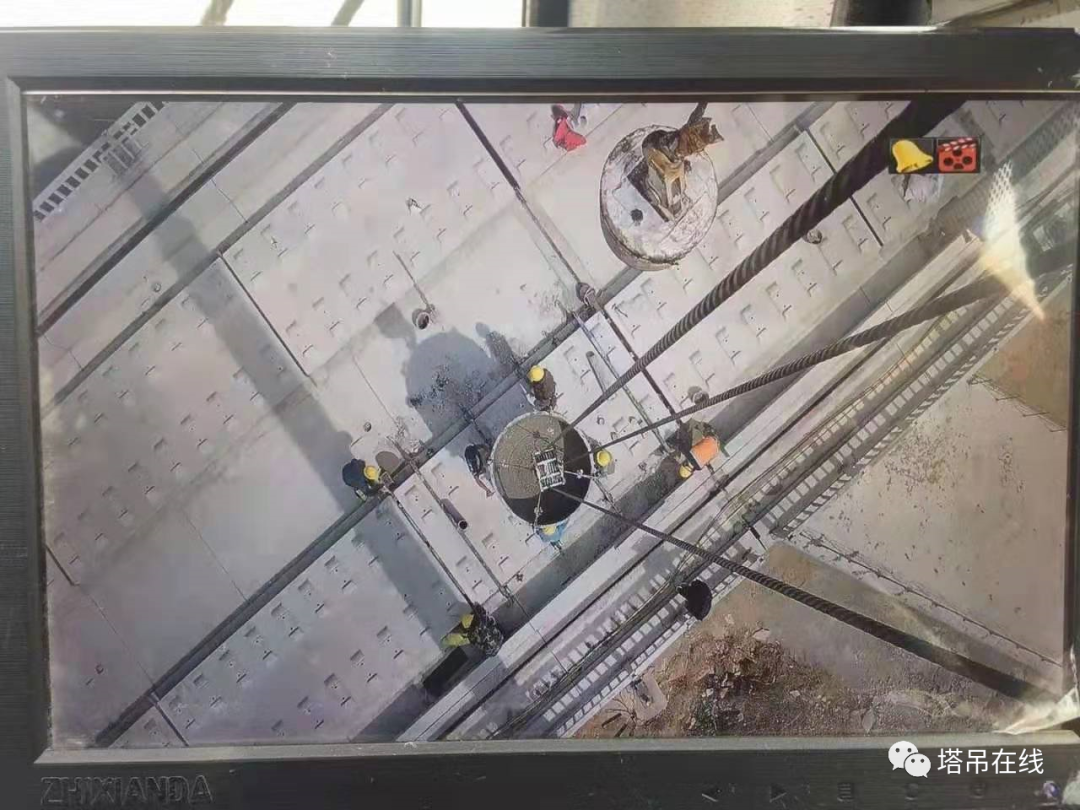

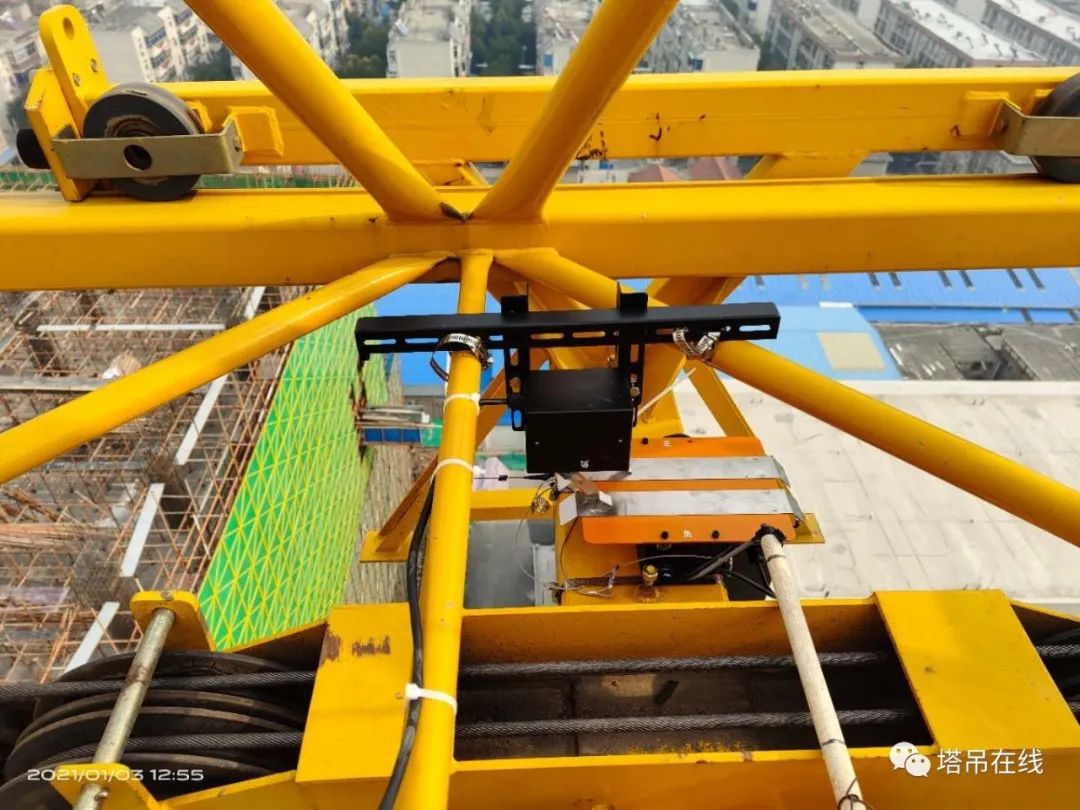

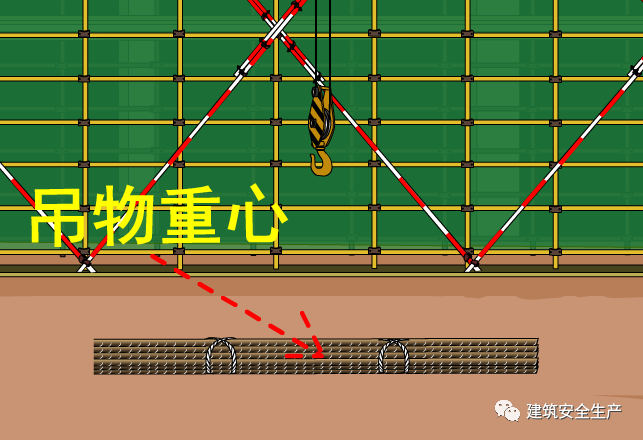

When lifting the hook, the hook should be located directly above the center of gravity of the object to be lifted.

He shall pay close attention to the suspended objects and surrounding conditions, and send out command signals in time if any problems are found.

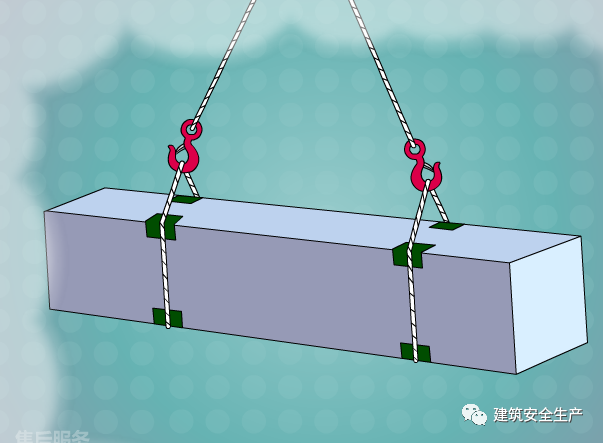

When preparing the sling, the weight and center of gravity of the object to be lifted should be estimated accurately, and the sling should be carefully checked for safety every time it is lifted, and it is not allowed to take chances to overload or use the scrapped sling.

2.

(4) Do not lift if the command signal is unclear.

It is not allowed to pull the hook to hang hard to prevent the object from turning and swinging after lifting.

Three signal workers’ safety operation requirements 1.

7.

Before lifting, check the binding of the lifting object and confirm that the connection points are firm and reliable.

When lifting large and heavy objects, an induction rope should be added.

The following is a brief introduction to the safety operation requirements of the construction crane rigger signalman in the operation process.

The construction crane rigger and signalman shall receive professional training and hold the Special Operation Qualification Certificate after passing the examination before engaging in lifting operation.

5.

The driver and commander shall not leave the post.

The length of the induction rope should enable the rigger to hold the rope head and avoid the right under the lifting object, so that the rigger can use the rope to control the lifting object in case of an accident.

6.

(3) Do not lift bulk goods if they are too full or not tied firmly.

Source | Construction safety production construction lifting rigger signalman refers to the person who is engaged in the preparation of slings, binding, hooking, unhooking, unloading and other work during the lifting operation, and the signal commander.

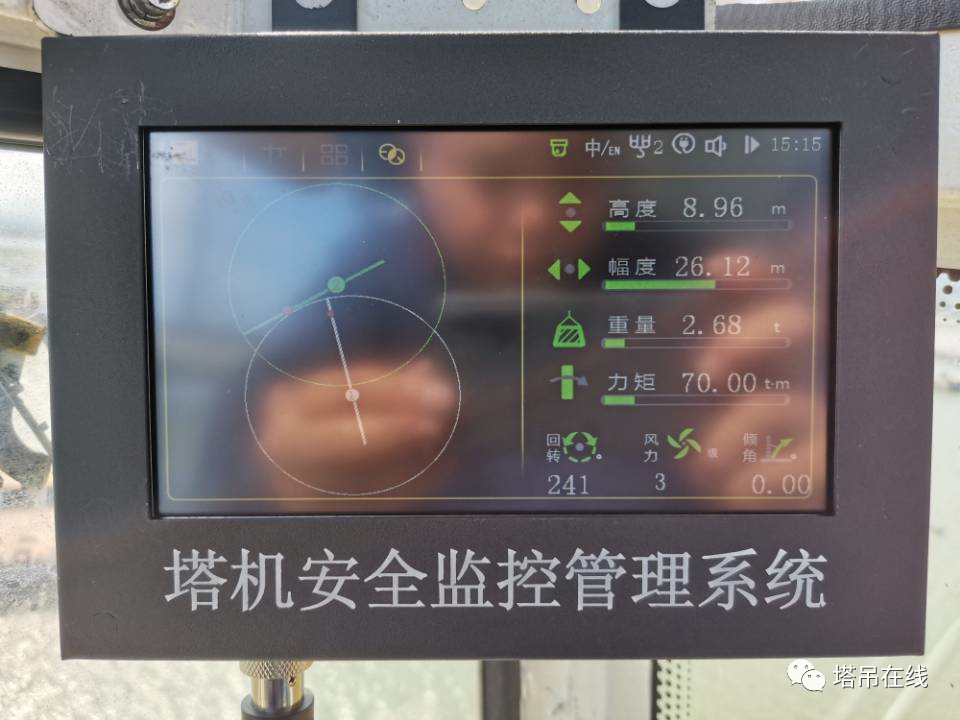

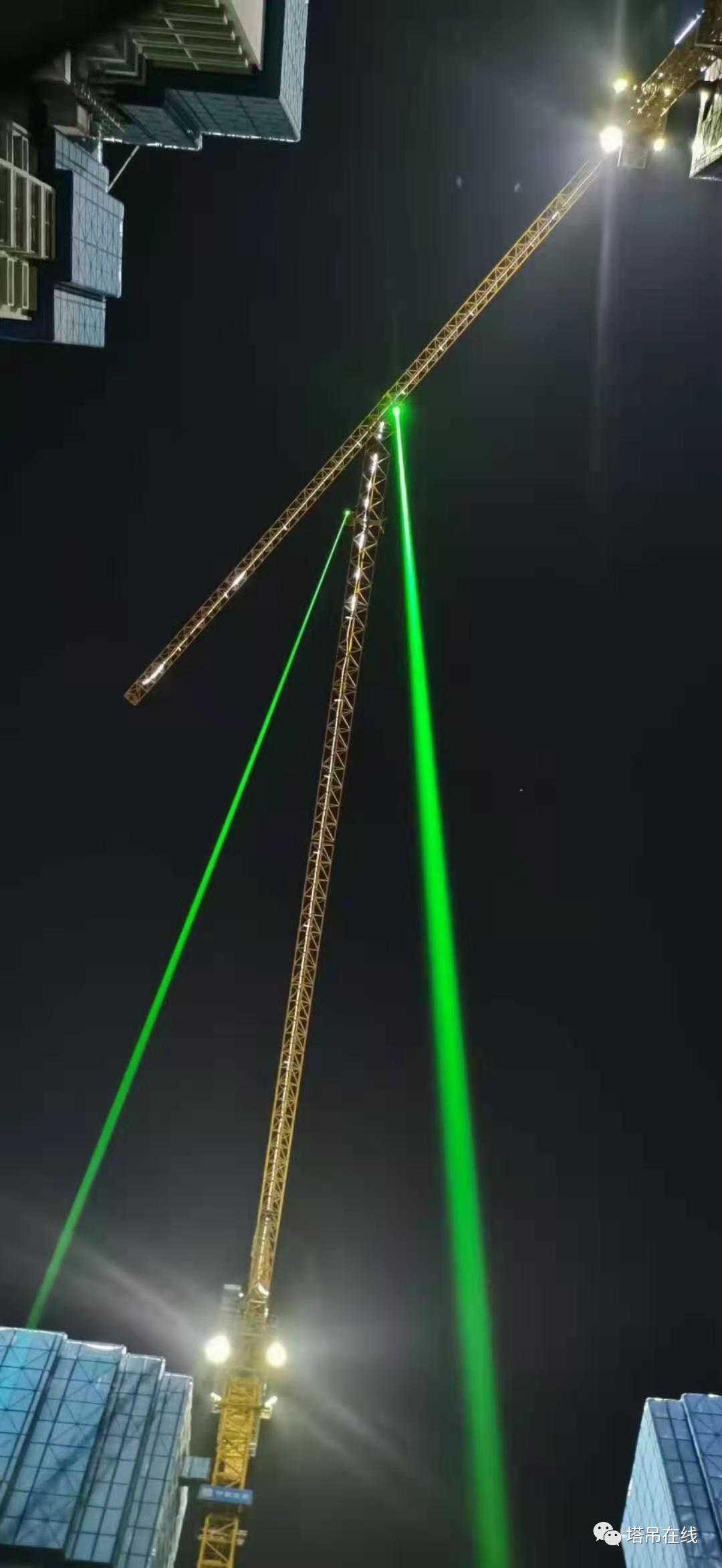

It is strictly forbidden to operate multiple tower cranes in the same area at the same time.

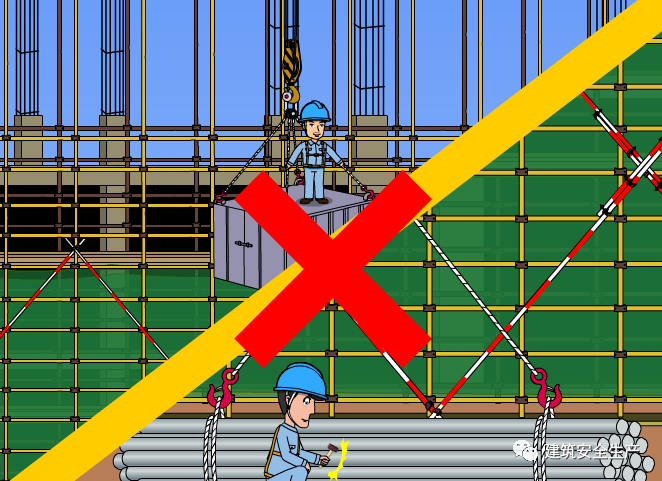

(6) Do not lift when standing on the lifting object.

1.

For command signals, refer to “Command Signals for Hoisting and Hoisting” (GB5082-85) for hand signals, semaphore signals and audio signals.

(5) Do not lift without protective measures when the edge of the object is sharp.

The second rigger’s safety operation requirements: 1.

During lifting, no one shall stay or walk under the boom, and the boom and objects must keep a safe distance from the overhead line.

It is forbidden to use objects that are easy to roll (such as logs, pipes, rollers, etc.) as foot objects.

When it is necessary to process it, put down the pad and brake the lifting arm, hook and rotary brake.

3.

2.

Confirm that all ropes are removed from the hook before lifting the hook.

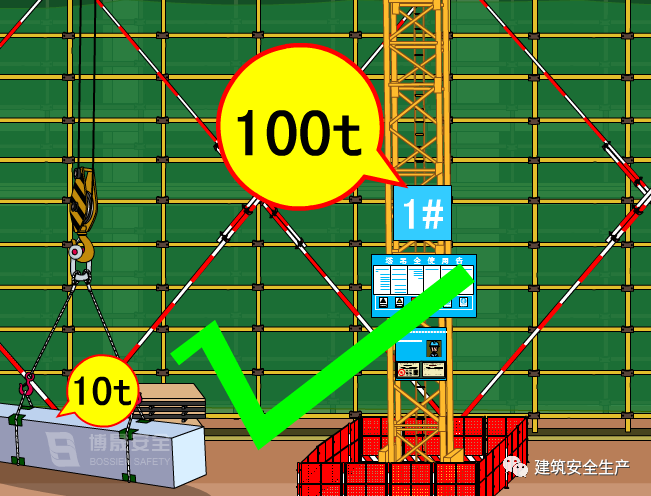

It is strictly prohibited to exceed the rated load of the lifting appliance when it is loaded.

Safety belt must be worn when climbing to prevent personnel from falling.

In order to prevent the occurrence of various accidents in the process of construction crane rigger signal work and ensure the construction safety, the construction unit must attach great importance to the safety training and education of construction crane rigger signal workers, so that the construction crane rigger signal workers can predict the accident prone and high-risk points in the operation in advance, and reduce the probability of accidents.

(2) Do not lift when overloaded.

Sling.

5.

The lifting objects shall not be squeezed by other objects, and the buried or frozen objects shall be completely excavated; (2) Cut off all connections with surrounding pipes and lines when binding the lifting objects to prevent overloading; (3) When binding the lifting object, remove the sundries on the surface of the lifting object or in the cavity, lock or bind the movable parts, and do not mix the lifting of objects of different shapes or sizes without special binding to prevent falling and hurting people; (4) The burr at the binding part of the lifting object shall be polished smooth, and the sharp edges and corners shall be padded to prevent the sling from being damaged after the lifting effort; (5) For lifting objects with smooth surface, measures shall be taken to prevent the sling from slipping or the lifting object from slipping after lifting.

9.

When the lifting object is high and needs to be padded to climb the hook and remove the hook, the foot object must be firmly padded.

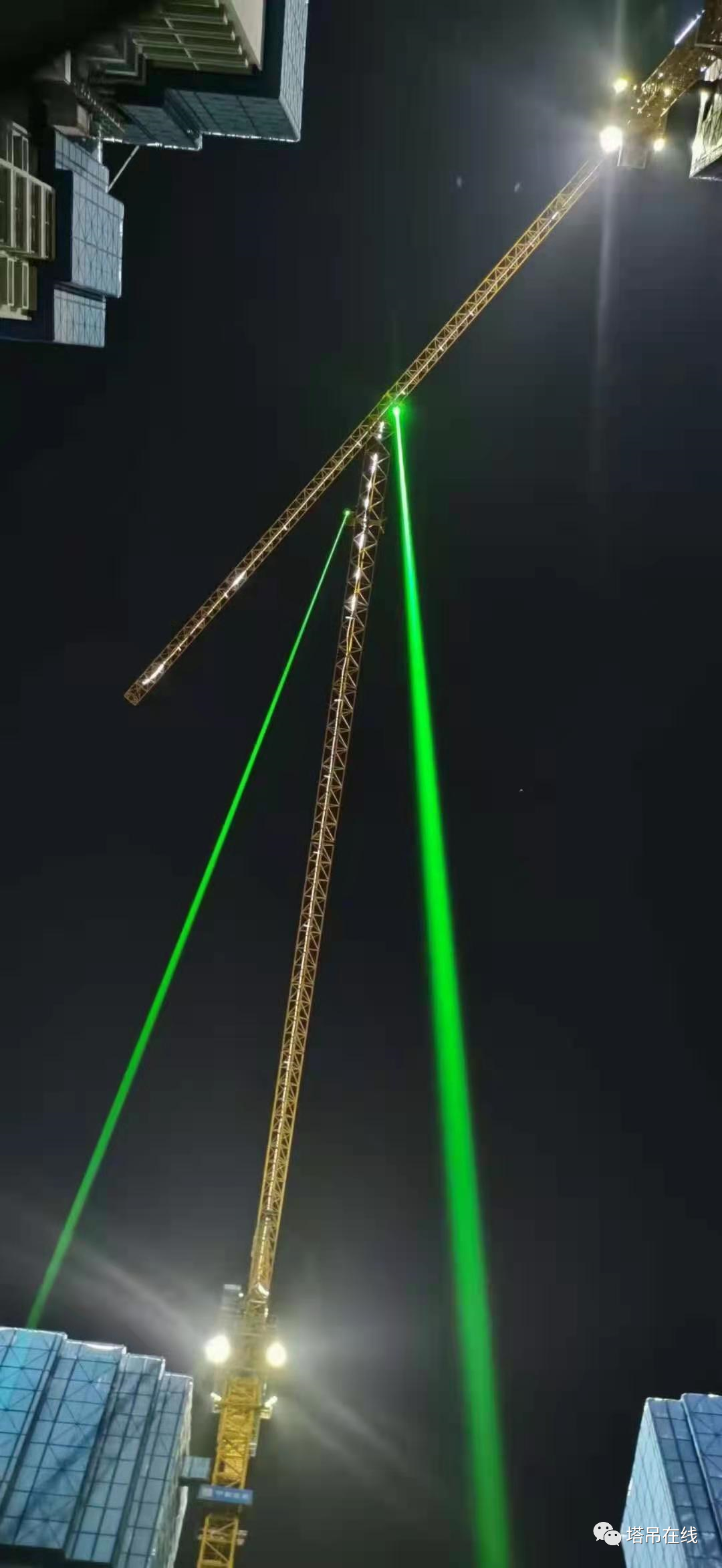

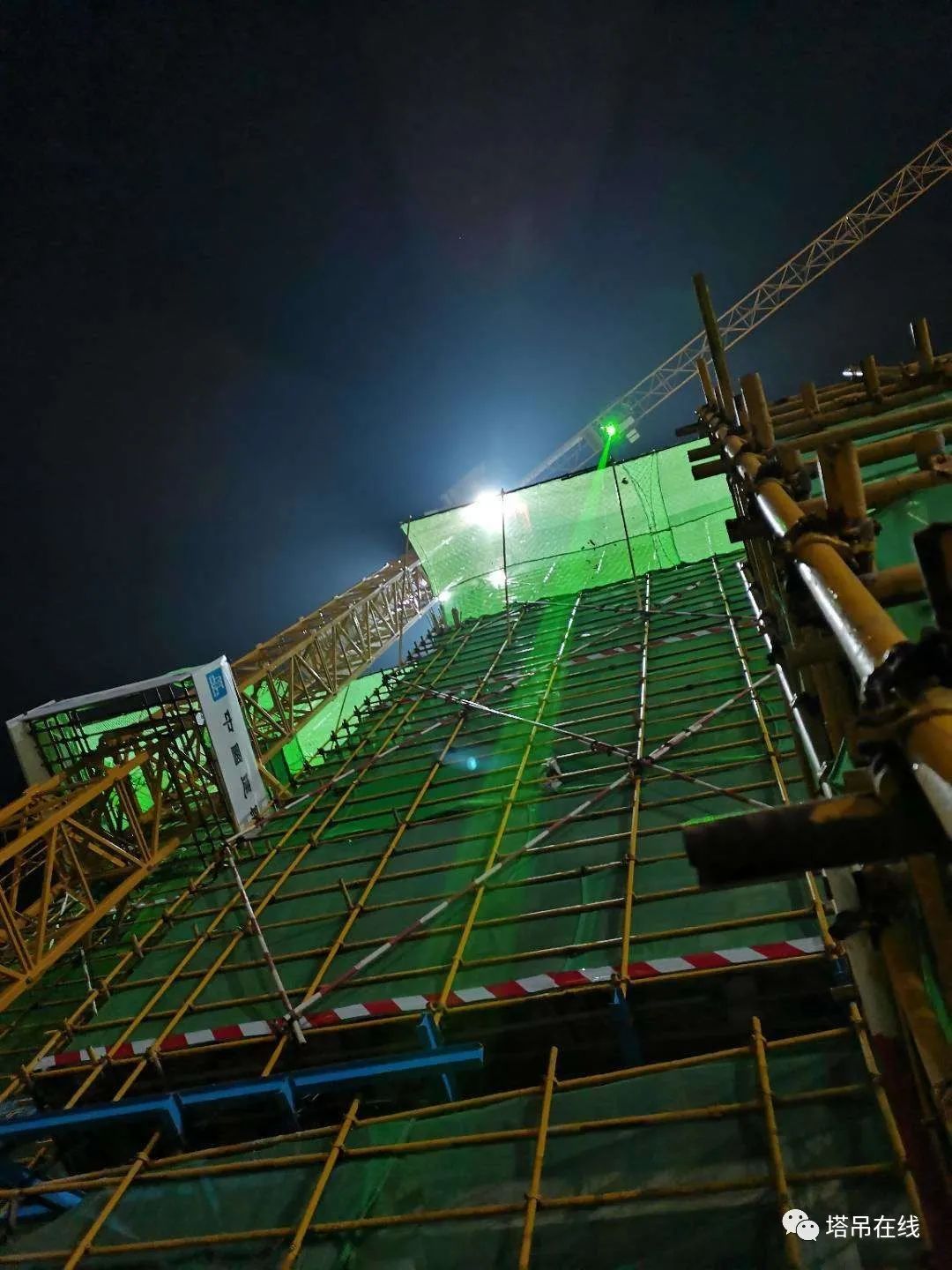

When multiple tower cranes are operating at the same time, the commanders of each tower crane shall strengthen the contact with each other to ensure the normal operation of each tower crane in each safe area.

4.

Binding requirements: (1) When binding lifting objects, necessary classification, cleaning and inspection shall be carried out for lifting objects.

Requirements for unhooking: (1) During unhooking and unloading, before the lifting object is transported in place, the placement position shall be selected, and the unloading shall not squeeze the electrical lines and other pipelines, and the passage shall not be blocked; (2) When unhooking, wait for all slings to be completely relaxed before lifting the hook.

The command signal must be clear and reliable, and the personnel must “follow the hook”.

When lifting the lifting object, the command personnel must see the lifting object reach the safe area, and it is forbidden to collide with other objects and facilities during the lifting.

3.

(7) Components buried underground shall not be lifted.

(9) If the light is dim and you can’t see clearly, don’t lift the object.

Before operation, strictly check whether all kinds of equipment, tools and rigging are safe and reliable, and overload use is not allowed.

5.

2.

8.

In order to improve the effect of safety training, it is necessary to improve the pertinence and interest of training courses, fundamentally change the expression of training content, and attract operators to learn safety knowledge independently.

.

According to the provisions of the Standard for Safety Inspection of Building Construction (JGJ59-2011), the crane operation shall be equipped with full-time signal command and rigging personnel, and one person shall not take into account both signal command and rigging operation.

(10) Do not lift in strong winds above level 6.

During the whole process of operation (especially when heavy objects are suspended in the air), the signalman shall not leave his post without permission.

General safety operation requirements 1.

3.

4.

The hook shall adhere to the “five non-hanging” principle: (1) Do not hang the hook when the weight of lifting or lifting object is unknown; (2) Do not hang if the center of gravity is not clear; (3) Sharp edges, sharp corners and slippery workpieces are not hung without padding; (4) Lifting appliances and supporting tools are unqualified or scrapped; (5) The package is loose and binding is not good.

4.

When lifting an object, it is forbidden to stand on the object or process it.

“Ten no lifting” for lifting operation: (1) No lifting for inclined lifting.

Precautions for hook lifting: (1) When more than one person hangs the same lifting object, a special person shall be responsible for the command, and the hook lifting signal can be sent only after confirming that the lifting is complete and all personnel are away from the safe position; (2) When lifting the hook, the ground personnel shall not stand at the place where the lifting object overturns or falls; (3) If the work site is inclined, you should stand above the inclined plane (not in the dead corner) to prevent people from being injured by the falling objects.

(8) Do not lift if the safety device fails.

It is not allowed to shake the rope to remove the rope, and it is not allowed to use the crane to pull the rope.