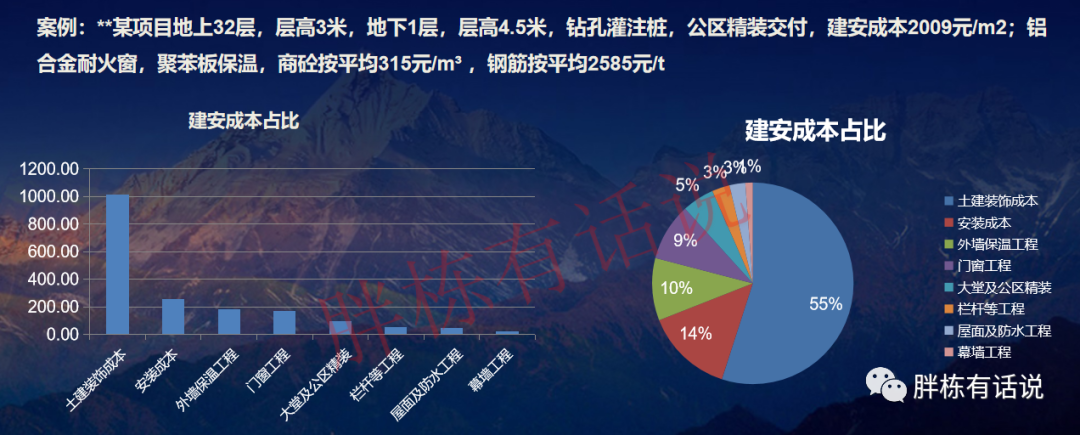

The building insulation project has always been a sub project that developers focus on, and the reasons for its focus are as follows: ① the insulation project is a rigid cost, and its cost can not bring customer perception, and the insulation cost has always been at the top of the construction and installation cost, so developers have to pay attention to the high cost and low owner sensitivity

.

② Thermal insulation falling off, thermal insulation failure, water seepage and other social events caused by thermal insulation emerge in endlessly

.

The project quality problems make developers have to face, and the thermal insulation complaint has always been an unspeakable pain for developers

.

Thermal insulation materials falling frequently ③ thermal insulation engineering has high professional degree, poor penetration and low management and control level, which is the project that the developer management end has to “submit to Party B”

.

The reasons can be summed up as follows: (1) developers lack systematic understanding of thermal insulation materials, many of them are led by material manufacturers, and many of them come from small workshops, so the quality of materials is difficult to control; (2) the contradiction between thermal insulation and fire prevention of building materials has not lasted for a long time

.

In the face of high energy-saving standards and strict fire prevention requirements, there are few non combustible materials, which can ensure the safety of buildings The thermal insulation industry is in chaos; (3) low price bid winning, layer upon layer subcontracting, thermal insulation industry chaos rebirth, bad money expelling good money phenomenon is serious; (4) new technology and new thermal insulation materials lack of systematic research, thermal insulation is very good, thermal insulation system may not be good, new material technology is lack of long-term engineering inspection, under this condition, it is necessary to large-scale application, it is easy to have problems

.

Some time ago, I read the potential risk analysis and standard response of external wall external insulation (second draft for comments) and benefited a lot, so I wrote this reading note

.

Please read the opinions in this paper dialectically

.

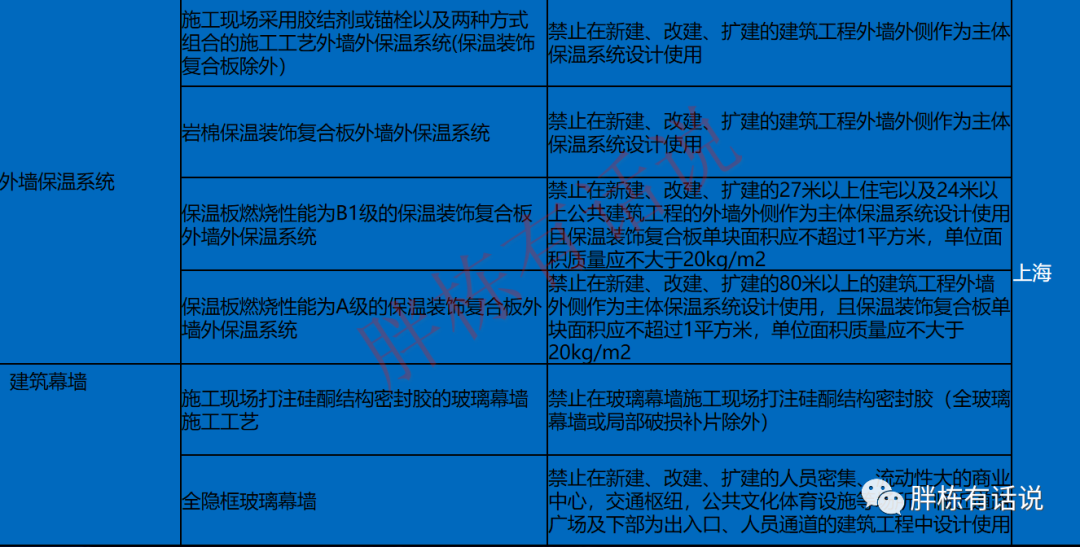

With the implementation of “code for fire protection design of buildings” in 2015, the external thermal insulation engineering of buildings is “suppressed” by the policy, and Shanghai even issued a document to prohibit the use of external thermal insulation in October 2020 (the figure below), which caused an uproar in the industry

.

The external thermal insulation is “suppressed” and “prohibited”, and the first thing to bear the brunt is “developers”, who are faced with the embarrassing situation of no materials available

.

As a result, the composite insulation system (structural insulation integration products) began to be familiar to developers

.

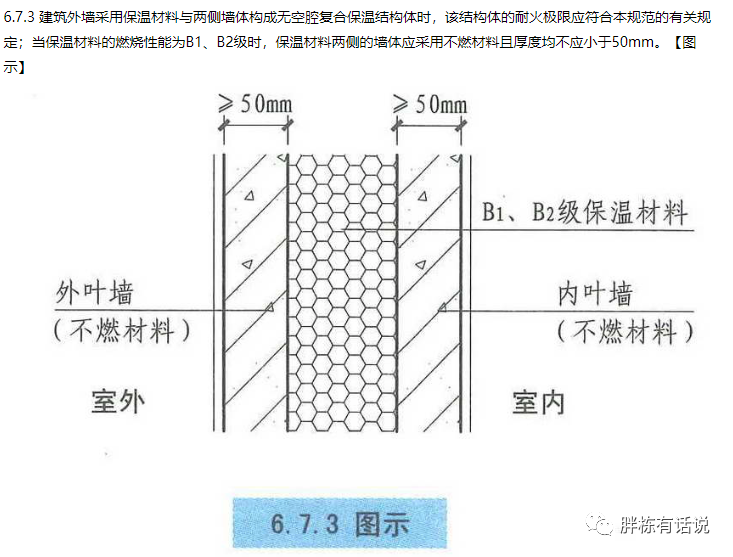

As shown in the following figure “code for fire protection design of buildings”: About sandwich insulation system (composite insulation system): according to the relevant views of the draft, the criticism of the sandwich insulation system is that although the insulation and structure can achieve the so-called “same life”, the sandwich insulation makes the temperature difference between the inner leaf wall and the outer leaf wall expand to seven to ten times, resulting in the shortening of the service life of the sandwich wall structure As short as 50 years (the service life of the structural system of the external thermal insulation project is 70 years, because the external thermal insulation can reduce the temperature difference and prolong the service life of the structure)

.

It is self-evident that the sandwich insulation system is to protect the insulation layer of the structure or the insulation layer to protect the structure

.

In addition, the steel mesh and anchor used in the connection between the sandwich insulation system and the structure greatly increase the risk of the thermal bridge, which is easy to cause later mildew

.

Third, the composite insulation system, no matter the cast-in-place concrete or insulation block on both sides, its external wall finishing engineering, especially the coating directly sprayed on the leveling mortar, does not conform to the principle of gradual change of the stiffness of the insulation engineering, which is extremely easy to lead to cracking and cracking of the finishing engineering

.

Photo source: potential risk analysis and standard response of external wall and external thermal insulation (second draft for comments) on internal thermal insulation system: [opinion draft] the temperature field formed by internal thermal insulation construction method will cause lifelong instability of building structure

.

The annual temperature difference between the external wall and the internal wall will reach seven times, and the stress of seven times of the temperature in different seasons of different walls of the same building will cause repeated wall cracks, roof waterproof damage, basement waterproof leakage and indoor cold bridge condensation, mildew and other phenomena, commonly known as the internal thermal insulation technology complex

.

Different insulation positions have different effects on the water vapor penetration of the wall

.

Internal insulation, sandwich insulation and self insulation all have condensation on the wall

.

Only the dew point of external insulation is not on the wall

.

In engineering practice, it is found that the internal insulation technology is constantly troubled by cold bridge, condensation, mildew, wall cracks and other phenomena, and there are certain risks in engineering application

.

On the external insulation system: first, the composite flexible gradual change of insulation system can solve the risk of cracking

.

[opinion draft] when multi-layer materials are combined, selecting materials with similar elastic modulus is helpful to release the internal concentrated stress and prevent the surface from cracking and other damage

.

Therefore, in order to avoid cracking, the material of each layer of the external insulation system can have a certain flexibility and the ability to absorb stress and deformation

.

The results show that the deformation of base concrete wall is 0.2 ‰ (temperature difference is 20 ℃); the deformation of rubber powder polystyrene particle slurry is 3 ‰; the deformation of anti crack protective layer is 5% ~ 7%; the deformation of flexible putty layer is 10% ~ 15%; the deformation of coating decoration layer is more than 150%

.

The deformation of the external insulation system gradually changes from the inside to the outside, which can reduce the internal stress concentration of the external insulation system, release the system stress and reduce the risk of cracking

.

Second: thin plastering system, originated from polystyrene board thin plastering, other kinds of materials are applied, problems emerge in endlessly

.

EPS thin plastering is an excellent thermal insulation material because of its low weight, small deformation and good self balance of water content

.

In recent years, especially since the implementation of GB 50016-2014, all kinds of plates (including stepless plates) have been applied with thin plastering system, but the material characteristics of these materials are very different from those of EPS, which leads to frequent problems of insulation shedding

.

Stress between insulation board and mortar comparison of various physical performance indexes of insulation board

.

The reason for the insulation system falling off is that there are many shear walls on the gable, and the probability of anchor failure is high

.

In addition, the most important reason is that the gable is extremely easy to produce negative wind pressure

.

If there is a cavity in the insulation paste, the wind pressure will produce thrust in the cavity, leading to insulation falling off

.

The point frame sticking method is usually used in the thermal insulation project, but the construction of thermal insulation project is mostly located at high altitude

.

If the construction workers do not strictly follow the point frame method, or the point frame method of cutting corners turns into pure point sticking method, the risk probability of thermal insulation falling off will increase

.

Note: some opinions in this paper come from “analysis of potential risks of external wall external insulation and standard response (second draft for comments)”

.

Due to the rush of time, the contents of opinions may be unknown, please understand

.

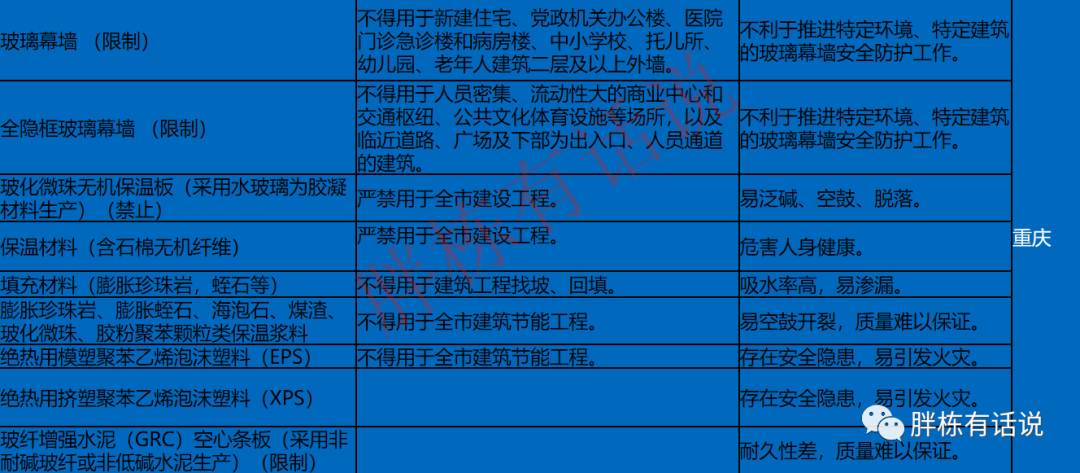

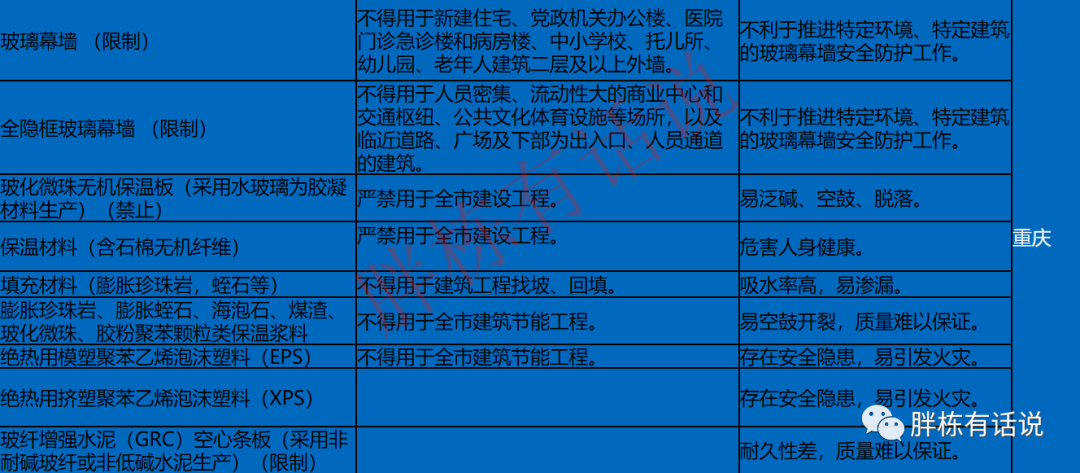

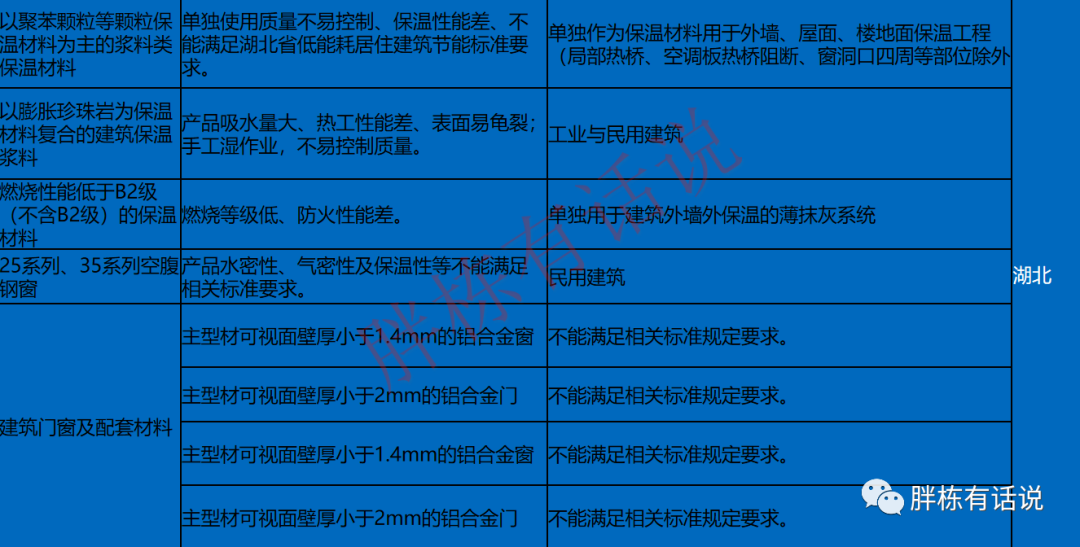

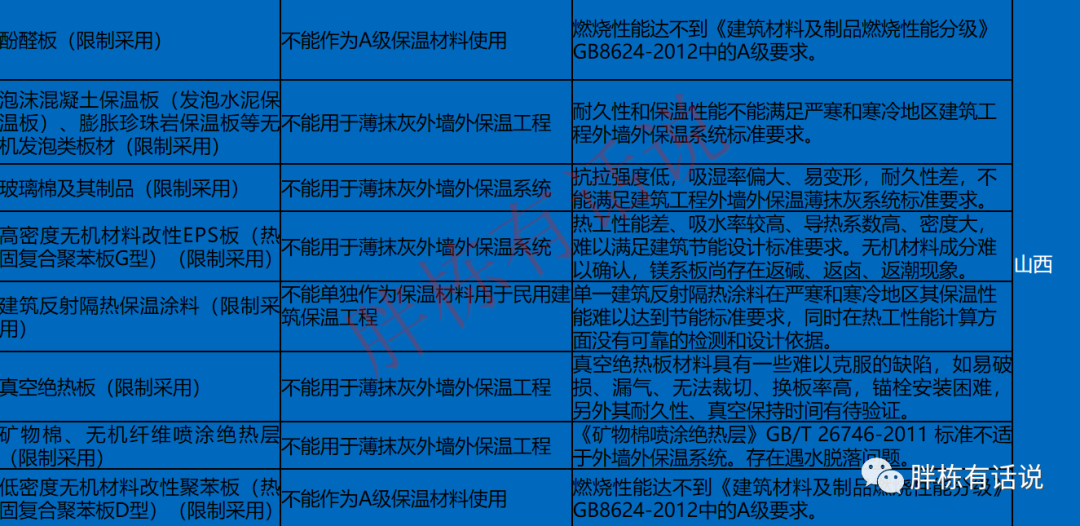

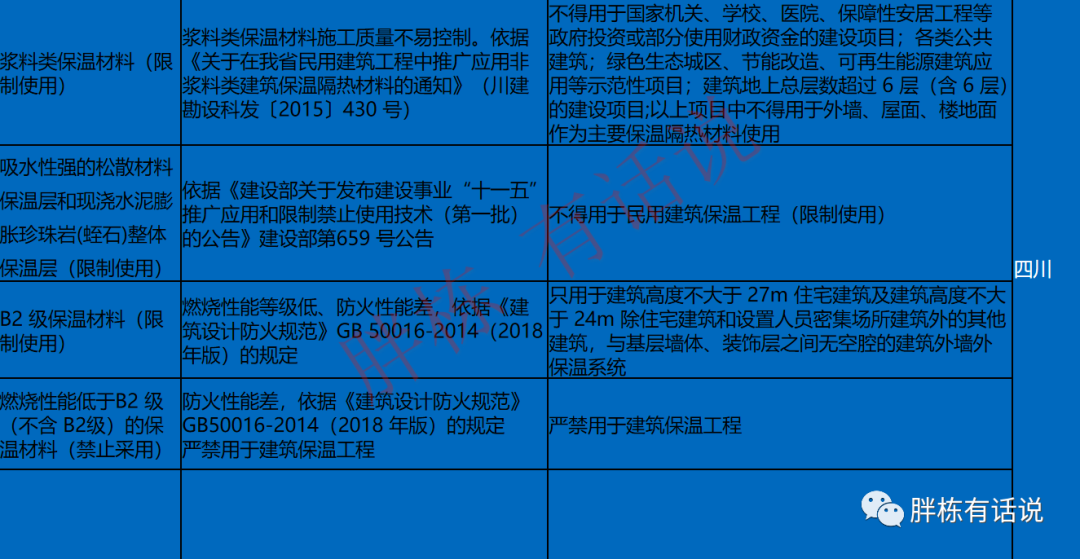

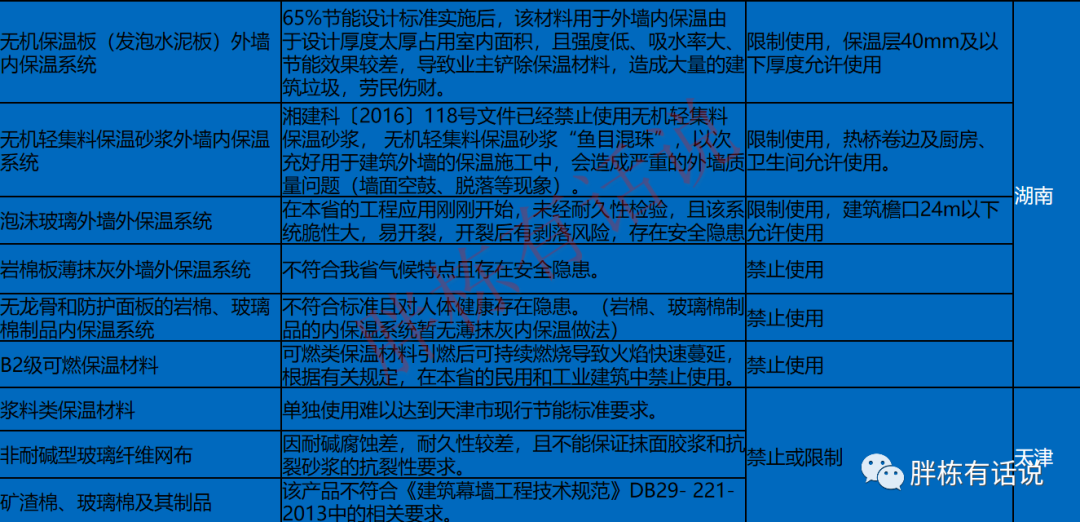

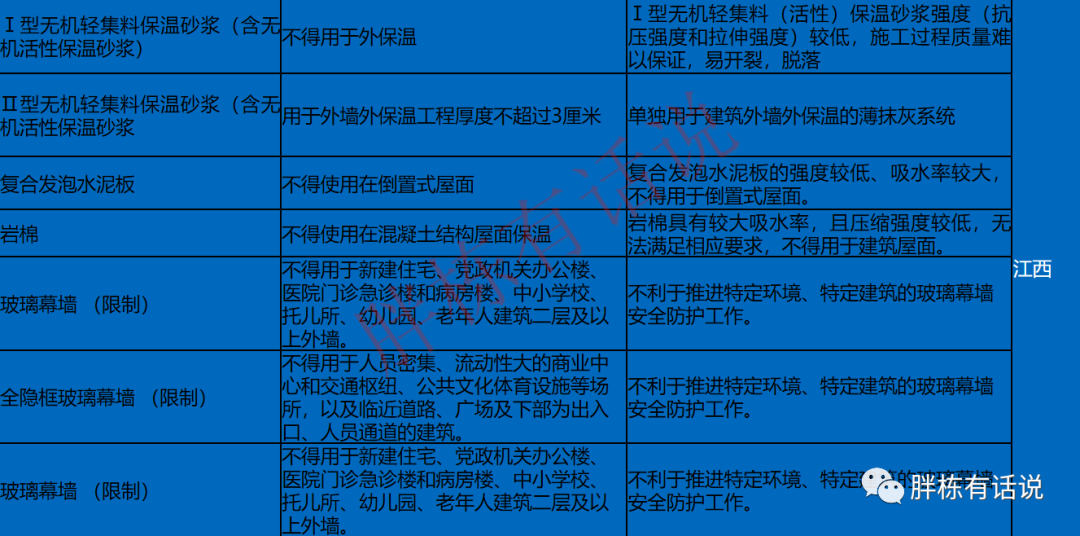

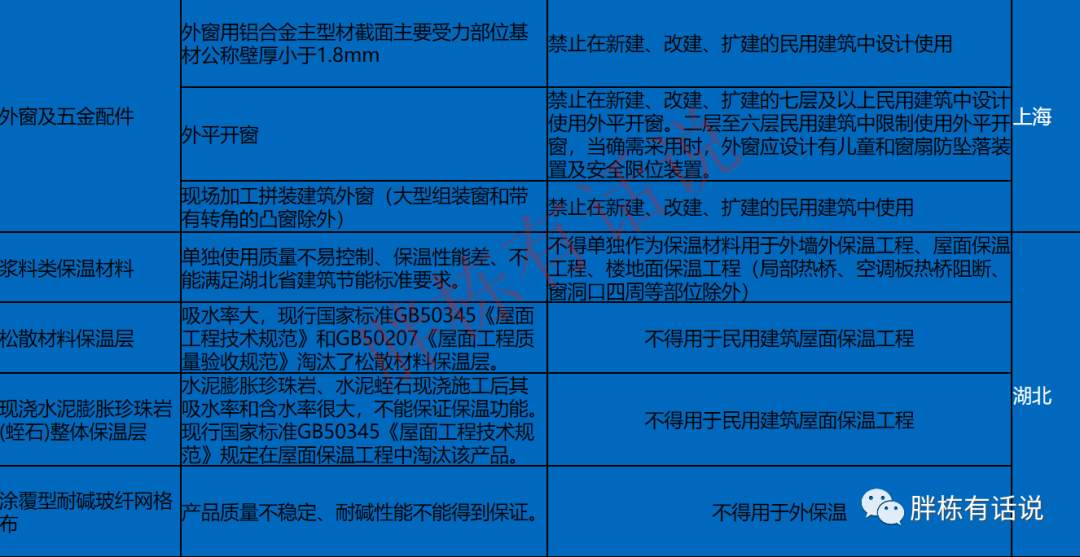

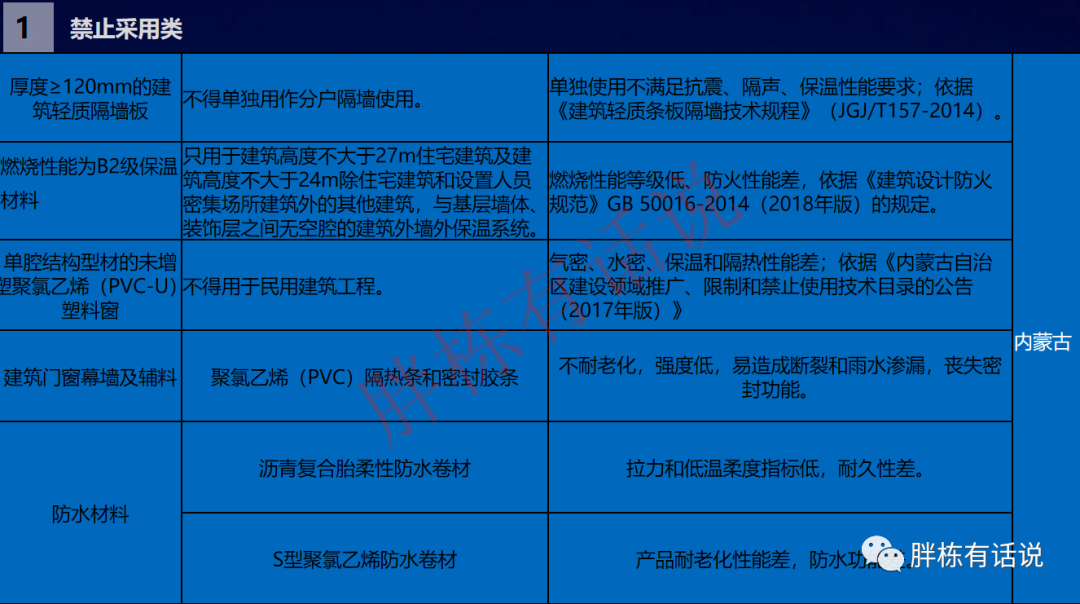

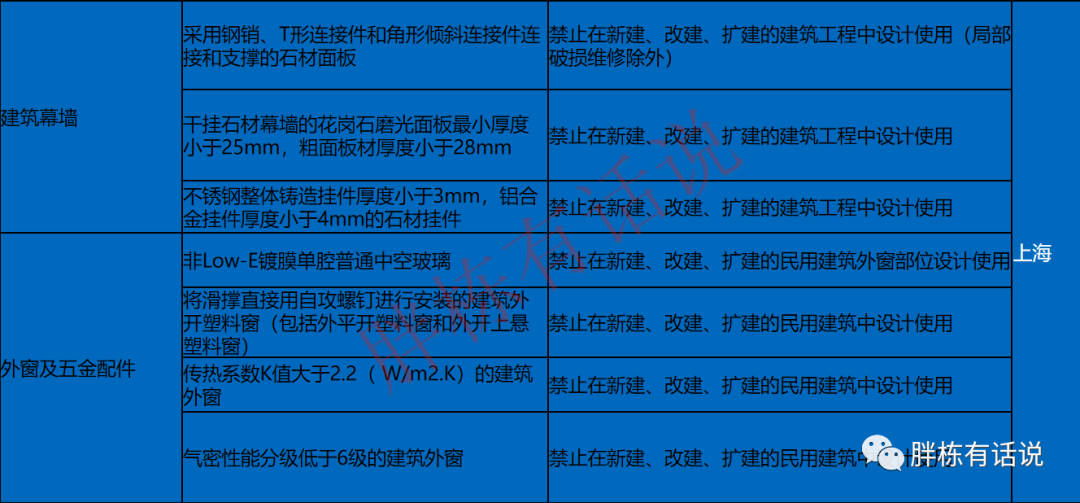

No.3 thermal insulation materials prohibited in recent years (click to enlarge the picture).

.