2.

If there is infringement, please contact to delete!) Long press QR code to follow us ▶▶▶。.

The formworks on both sides of the opposite side shall be continuously installed according to the wall sideline (the door opening is disconnected).

Roughening the base course: roughening the concrete on the structural beam surface in the side line of the toilet wall.

Positioning and setting out: the construction survey department pops up the positioning sideline of the opposite wall according to the construction drawings.

Rebar planting in boreholes: 200 hole spacing Φ 6.

HZJA 5.

6.

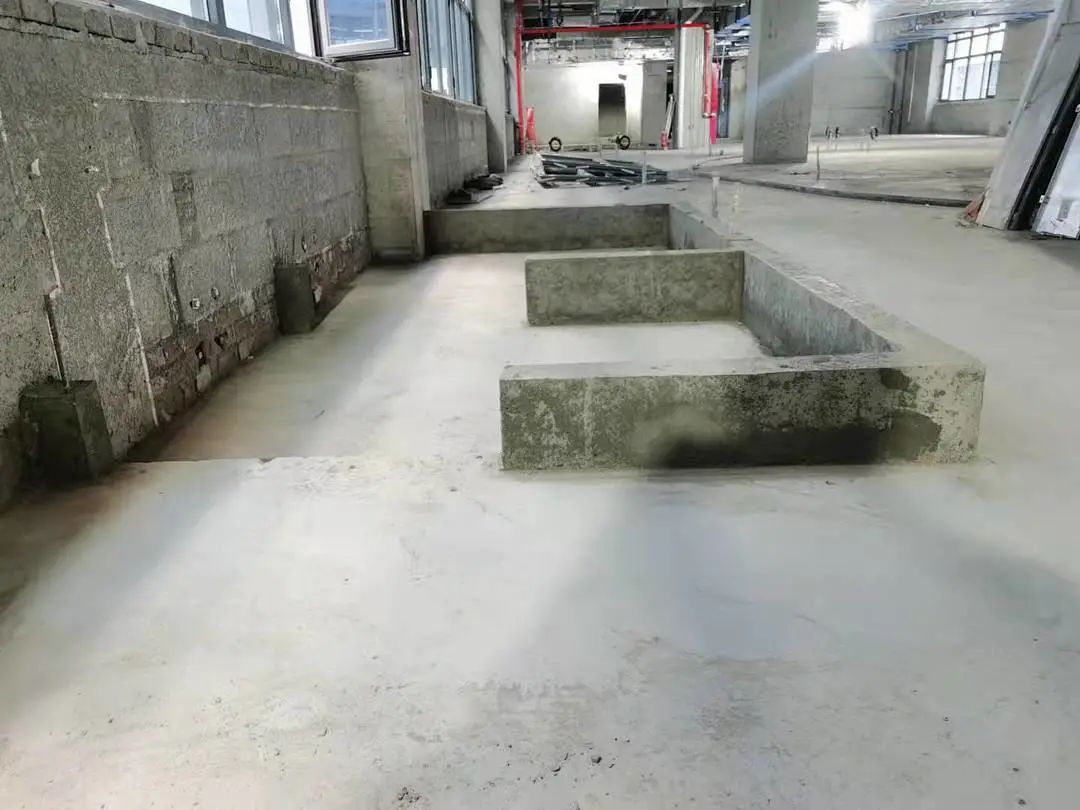

Construction method of toilet water stop inverted sill 1 Base course cleaning: the side formwork of the hanging plate in the floor shall be removed and cleaned, and the laitance layer and sundry layer on the floor shall be chiseled and cleaned.

Reinforcement head, the insertion depth of drilled reinforcement shall not be less than 8cm, and the exposed reinforcement shall not be less than 18cm.

The concrete scattered on the floor shall be cleaned in time.

When pouring concrete with hzja finished product protection method, the floor shall not be polluted.

4.

It is forbidden to penetrate the pull wire for reinforcement.

Pouring of reverse side concrete: before pouring the reverse side concrete, lay a layer of 2cm cement mortar (waterproof agent with 5% of the weight of cement); C20 reverse side concrete pouring: during concrete pouring, insert and tamp the reinforcement and knock the side formwork with a hammer to make the concrete dense; After concrete pouring, the surface shall be compacted and leveled.

Hzja (source: integrated on the Internet, the pictures and copyright belong to the original author.

Installation of side formwork: the construction survey department shall snap the 1m control horizontal line of the building on the wall, and the construction team shall control the formwork installation height on the opposite side according to the 1m control line.

3.

8.

Base course flushing: the base course shall be cleaned with water, and there shall be no ponding on the base course surface.

When vibrating the concrete, the formwork shall not be displaced.

7.

The stay wire shall be straightened, the square timber shall be nailed on both sides, the presser foot plate shall be nailed on the bottom, and the pull strip shall be nailed on the upper opening for reinforcement.

Curing: after the final setting of concrete, a specially assigned person shall water and maintain it for at least 3 times a day.