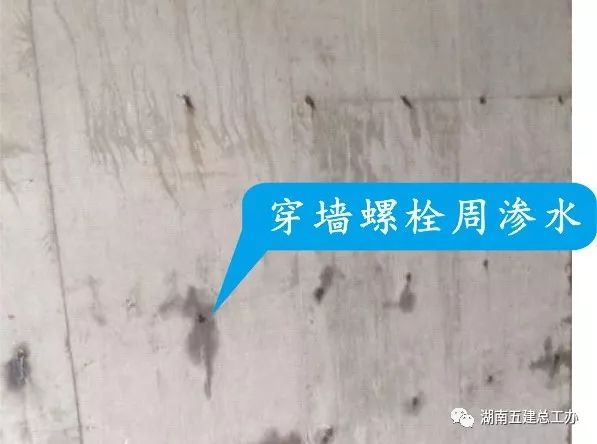

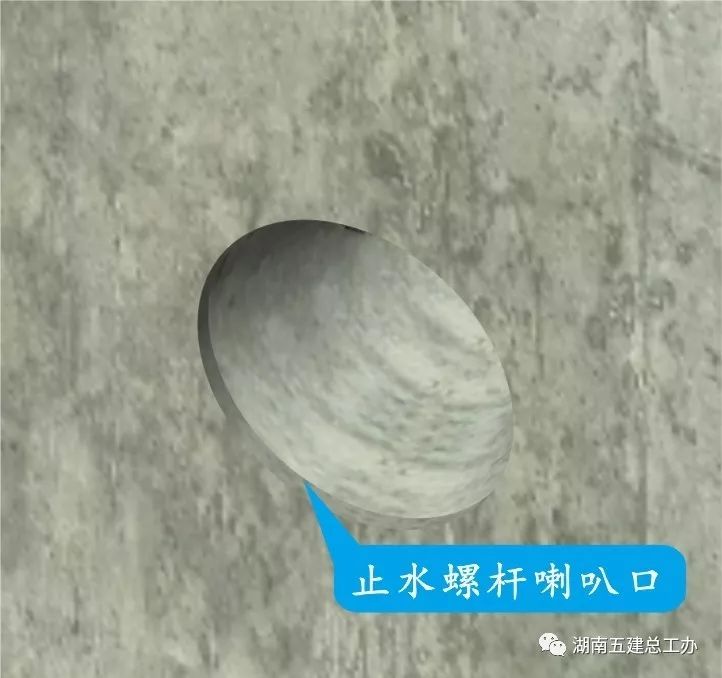

Causes: the size of the water stop ring of the through wall screw is too small or not fully welded or not fully welded, and the formwork is removed too early, resulting in the disturbance of the concrete around the screw

.

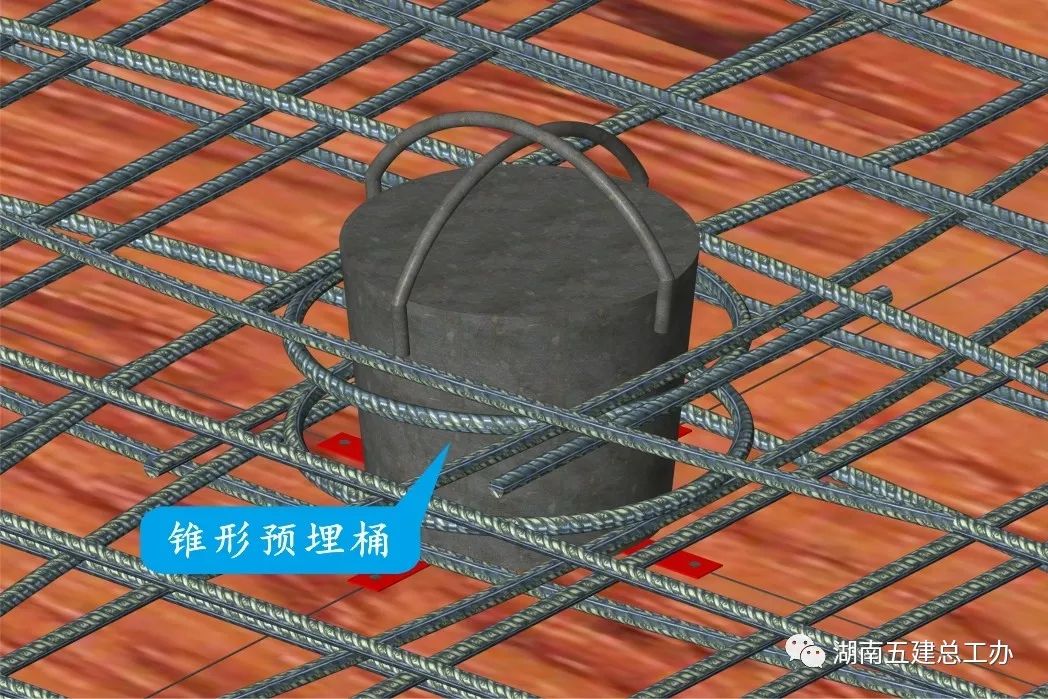

If there is a large hole in the top plate, it shall be strengthened locally

.

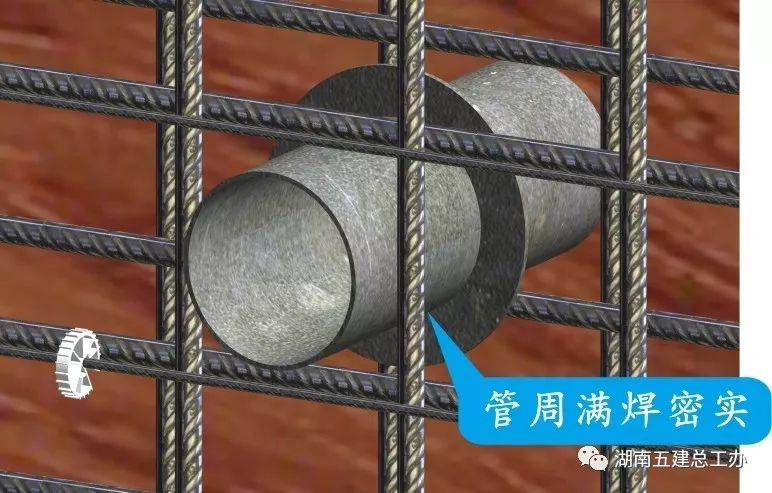

06 manifestations of water seepage around the pipe: there is water leakage at the place where the embedded casing and directly buried pipe pass through the waterproof concrete wall

The early strength of concrete is low, which is caused by drying shrinkage during hydration and curing

.

13 the corner of the base course of the cushion waterproof layer shall be made into a circular arc or obtuse angle

.

Causes: the basement roof is not thick enough or too thick, the concrete mix proportion and materials are improper, the vibration is not dense and the maintenance is poor

.

Basement crack prevention measures 01 waterproof concrete adopts low hydration heat cement, mixed with crack resistant fiber and expansion agent, and the grading of coarse aggregate shall be continuous

.

09 all kinds of steel bars or binding wires set inside the waterproof concrete structure shall not contact the formwork

.

03 water seepage manifestation of floor cracks: cracks and water leakage appear in the basement floor

.

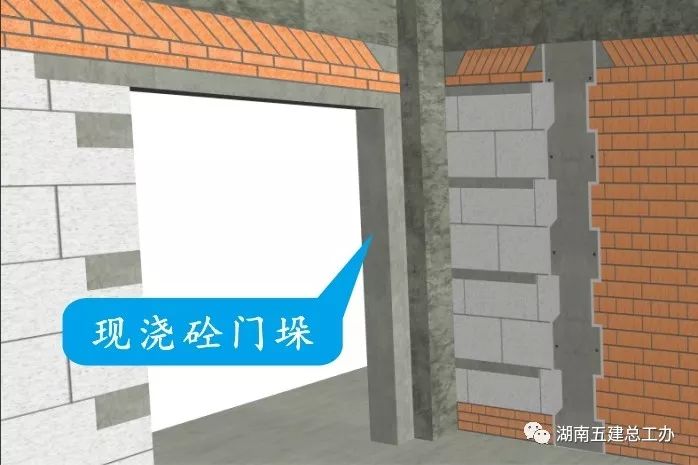

Cause: circular holes are not embedded in floor construction holes or the holes are too large, and reinforcing bars are not set around the holes

.

Special personnel shall be arranged to tap the formwork gently to track and check whether the pouring and vibration are in place

.

The line pipe is located on the double bottom reinforcement of the top plate and should not be close to the upper part of the top plate

.

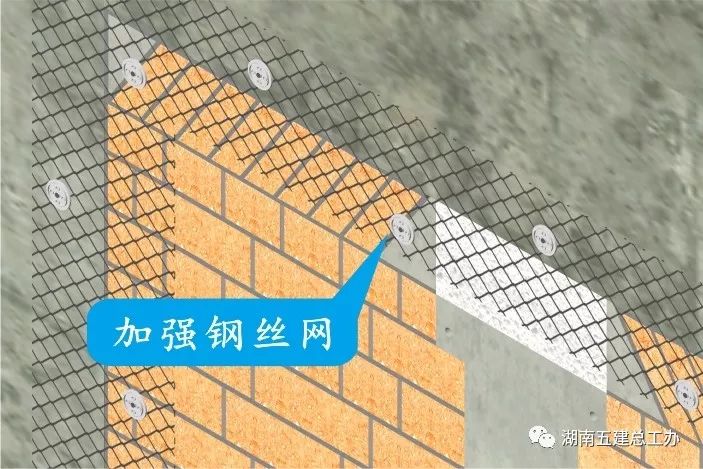

Crack resistant reinforcement mesh shall be added outside the main reinforcement of the wall at the upstream surface of the outer wall of the basement, and the spacing of reinforcement mesh should be 100-120mm

.

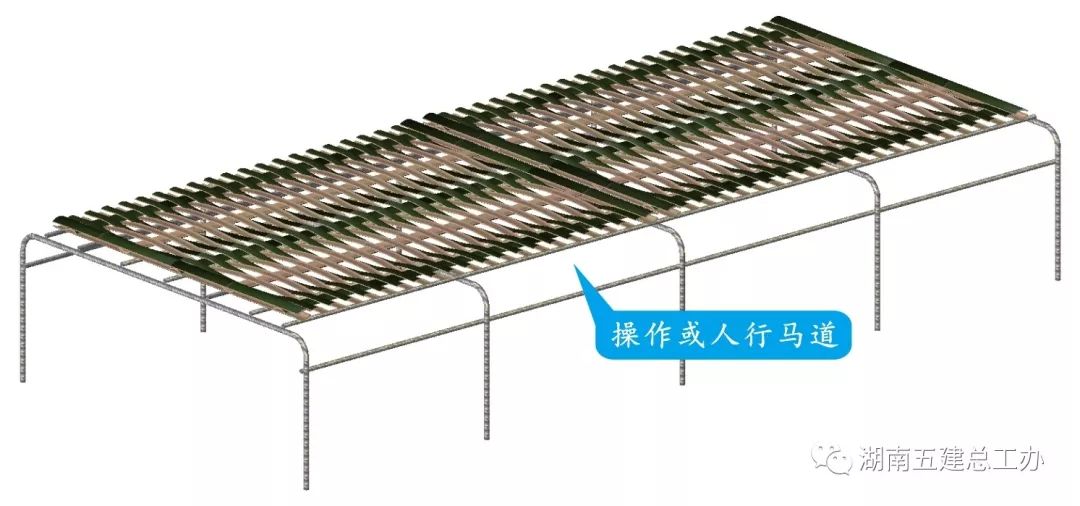

03 the curing with formwork shall not be less than 2 days after the pouring of basement exterior wall concrete

.

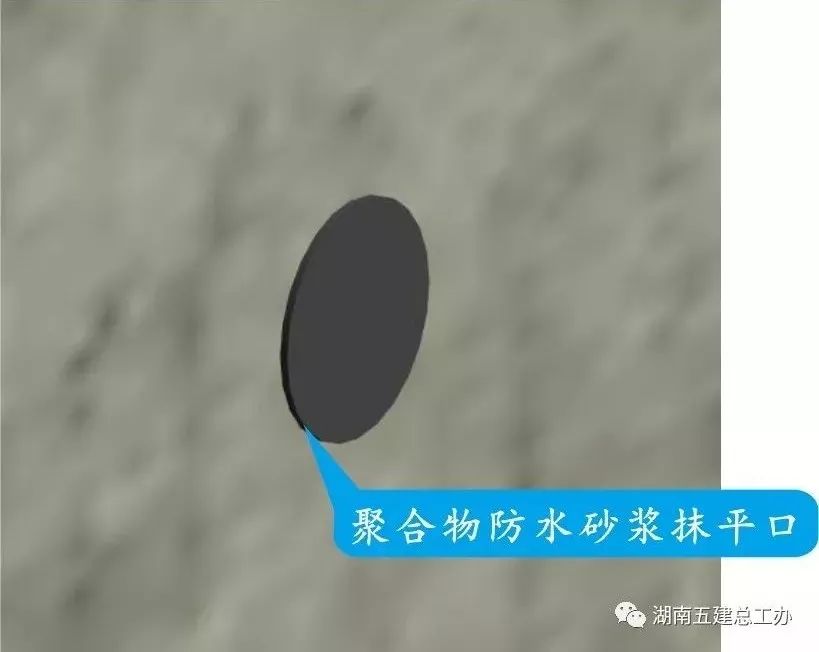

After the formwork is removed, the left groove shall be sealed tightly with sealing material and leveled with polymer waterproof mortar

.

Cause: the diameter of the embedded conduit is too large or the thickness of the floor is too thin, or the placement position is unreasonable and is not placed in the middle of the floor

.

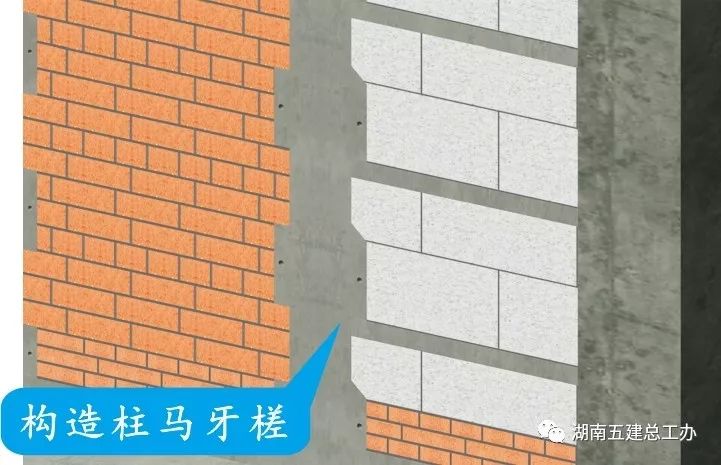

21 common cracks in Construction Engineering: form, cause, prevention and control, summarized! Aiming at 21 common cracks in construction engineering, this paper summarizes the forms and causes of various cracks from three aspects: ① basement cracks, ② floor cracks and ③ infilled wall cracks, puts forward prevention measures, and recommends engineering friends to collect and study! Chapter I basement cracks seven forms and causes of basement cracks 01 water seepage manifestations of vertical cracks: after the construction of the main structure of the basement, there are vertical cracks and water leakage in the middle area of the reinforced concrete wall and the edge of the retaining column

.

When pouring concrete, water it first, then pour the concrete in time, and vibrate it tightly

.

06 waterproof concrete shall be poured continuously in layers, and the thickness of concrete layers shall not be greater than 500mm

.

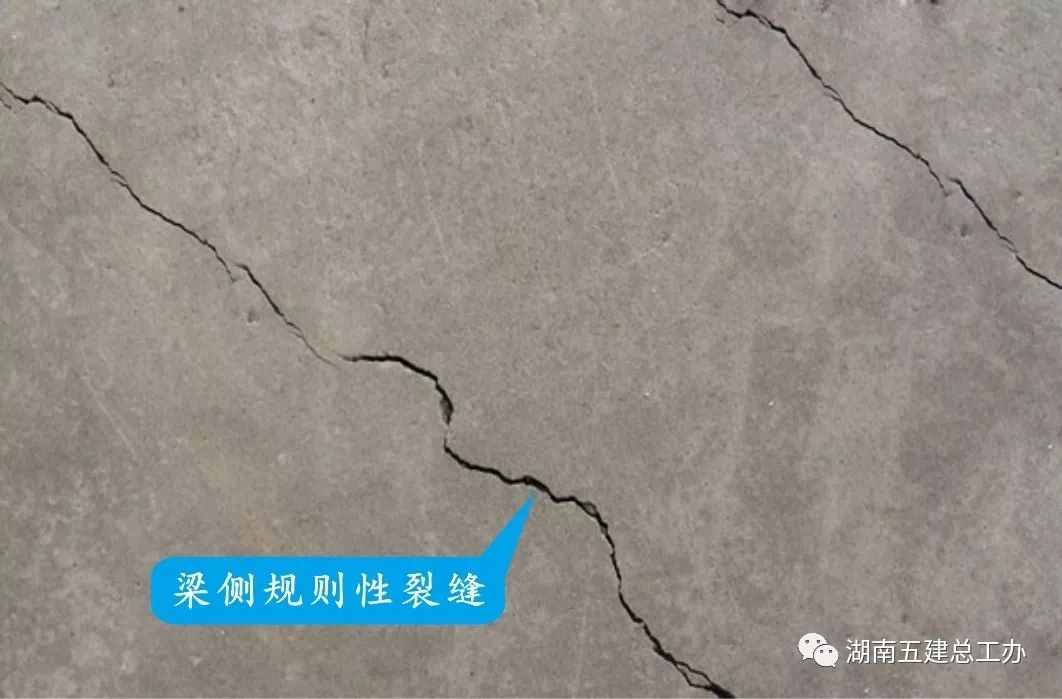

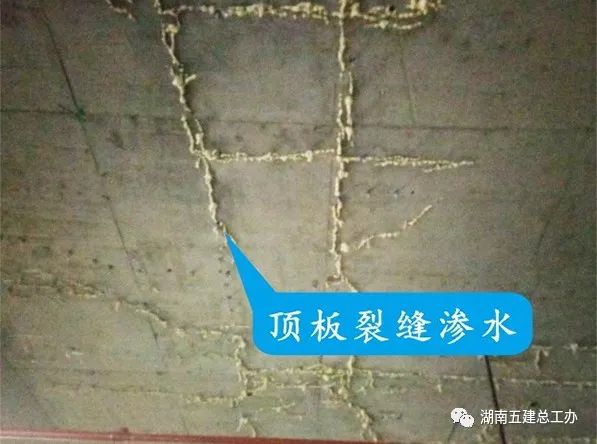

04 roof crack water seepage manifestation: regular well shaped block cracks and water leakage appear on the basement roof

.

02 during the transportation and pouring of ready mixed concrete, it is strictly prohibited to add water at will.

.

05 the through wall water stop screw and water stop ring shall be fully welded and full

.

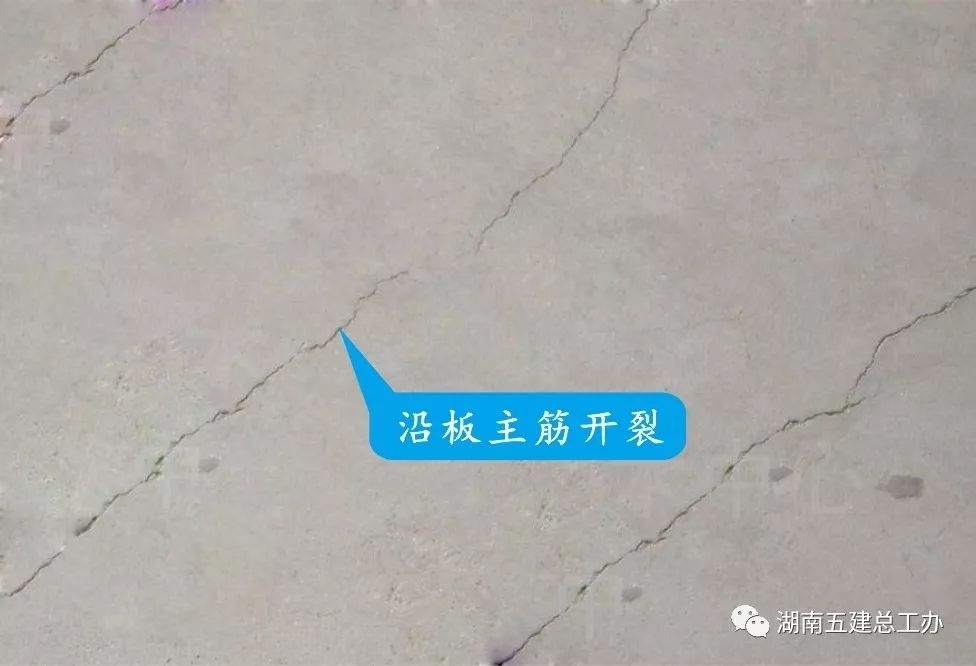

Causes: the floor bottom reinforcement and surface reinforcement protective layer are too small, and the vertical distribution reinforcement protective layer is too large or there is no distribution reinforcement, resulting in micro cracks in the reinforcement part

.

Causes: the waterproof concrete does not use low hydration heat cement or does not mix crack resistant fiber and expansion agent, and the formwork is removed prematurely and poorly maintained

.

Improve the early strength and appropriately increase the reinforcement

.

It must be fixed firmly during installation without looseness

.

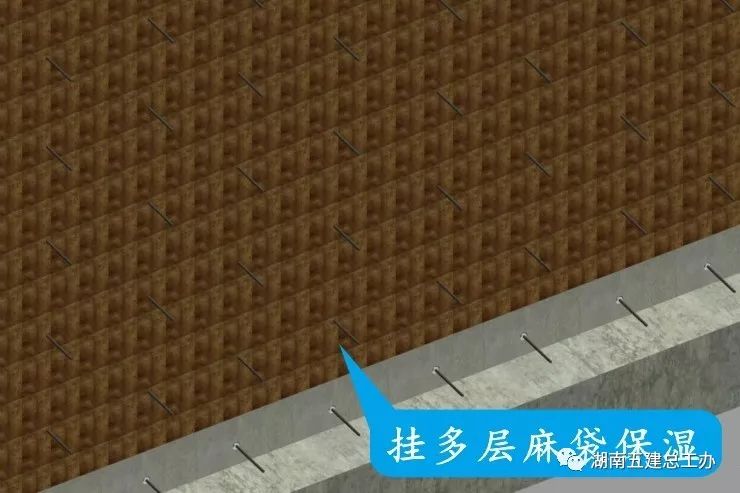

The thermal insulation and curing time shall not be less than 2 days and the moisturizing curing time shall not be less than 14 days

.

02 the basement floor concrete shall be vibrated twice before the initial setting

.

After the final setting, it shall be covered with plastic cloth and multi-layer materials with strong water retention for thermal insulation and moisturizing maintenance

.

15

.

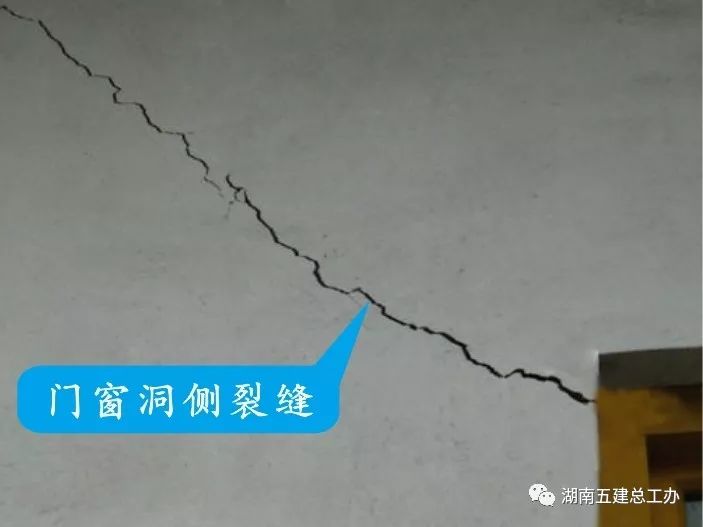

04 manifestations of cracks around embedded box holes: extended cracks are generated along the four corners of the holes for construction reserved holes and hydropower embedded boxes

.

08 during the construction of underground works, the groundwater level shall be kept more than 500mm lower than the waterproof concrete, and the groundwater shall be discharged

.

Cause: insufficient reinforcement of negative bending moment reinforcement on beam surface or excessive protective layer of negative reinforcement due to trampling of reinforcement

.

It is strictly prohibited to use foam board to fix, and the reinforcement is strengthened in this part

.

After the completion of the waterproof layer, the finished product shall be protected

.

The last concrete pouring of each layer shall be completed before the initial setting to avoid construction cold joints

.

Before the final setting, it shall be mechanically grinded and pressed manually for many times

.

05 manifestations of water seepage at roof junction box: water seepage at basement roof junction box or line pipe

.

Cause: the layout of junction box and conduit on the basement roof is unreasonable, and the reinforcement at the junction box position is not strengthened

.

03 expression form of oblique crack at the corner of floor slab: oblique crack occurs at the corner of cast-in-situ floor slab

.

Causes: the concrete vibration is not dense, the thickness of the bottom plate is not enough or the span is too large, or the settlement of the building is too large, resulting in excessive bottom plate reaction, and the design of anti floating pile and anchor rod is unreasonable

.

14 the basement roof line box uses a small round box, and the back is fixed with iron or shape steel

.

07 expression form of irregular crack: irregular crack appears on the surface of cast-in-situ floor slab

.

Chapter II floor cracks seven forms and causes of floor cracks 01 manifestations of penetrating cracks: penetrating cracks appear in the middle of cast-in-place floor

.

The molding temperature of mass waterproof concrete shall not be higher than 30 ℃

.

There is surcharge on the basement roof or the heavy transport channel is not reinforced

.

Each layer of waterproof coiled material shall be paved firmly, and an additional layer of coiled material shall be added, which shall be bonded tightly according to the shape of the corner

.

When the basement roof is used as temporary storage yard, equipment base and heavy transport road, it shall be subject to structural checking calculation, and reinforcement such as adding support in the basement

.

Floor crack prevention measures 01 optimize the concrete mix proportion, and strictly control the total amount of admixture, cement and other admixtures

.

The net width of the ring shall not be less than 40mm, and the sleeve with large diameter shall not be less than 80mm

.

20-40mm cement mortar with the same concrete mix proportion shall be pre poured at the horizontal construction joint of the wall (special chute shall be used to deliver the slurry in place), and then poured in layers (no more than 500mm)

.

05 manifestation of cracking along the main reinforcement of slab: micro cracks appear along the reinforcement of cast-in-situ slab

.

07 before pouring concrete at the construction joint of post cast strip, the laitance and sundries on its surface shall be removed, chiseled to the dense concrete, and then laid with coarse aggregate removed cement mortar

.

11

.

10 all embedded parts passing through waterproof concrete must be fully welded with water stop ring, and the weld shall be dense and seamless

.

02 expression form of regular cracks on beam side: regular cracks appear on both sides of the beam on the upper surface of cast-in-situ floor slab

.

When the internal and external difference of concrete is greater than 25 ℃, surface insulation and internal cooling measures shall be taken

.

Reasonably set the spacing of post cast strip

.

Causes: the mix proportion and materials do not meet the requirements, or water is added on site, resulting in excessive collapse, excessive surcharge, premature formwork removal and poor maintenance

.

The roof covered with soil adopts hollow floor

.

12

.

02 water seepage manifestation of construction joint: there is water leakage along the joint between the old and new concrete of basement deformation joint and construction joint

.

17

.

Causes: the basement bin is too large or the setting of deformation joint and construction joint is unreasonable, and the construction joint interface is treated carelessly or poured with pressure water

.

06 manifestation of cracking along the embedded pipe: cracks are easy to occur along the embedded line pipe in the cast-in-situ floor slab

.

04 mechanical vibration shall be adopted for waterproof concrete pouring to avoid missing vibration, under vibration and over vibration and ensure the uniformity and compactness of concrete

.

Cause: no radioactive reinforcement is set at the outer corner of the end room, and the floor is loaded too early or too heavy or too concentrated

.

Cause: the water stop ring is not welded on the through wall casing, or the specification and size of the water stop ring do not meet the requirements, and the welding quality of the water stop ring is poor

.

Pouring in the foundation pit and foundation trench with ponding is strictly prohibited

.

The total effective curing time shall not be less than 14 days

.

Cause: the water cement ratio of concrete is too large or the grading of coarse and fine aggregate is poor, the secondary collection and plastering time is unreasonable, and the trowel is not used for compaction and troweling

.

16 during the joint review of construction drawings, focus on and review whether the design and layout of anti floating piles and anti floating anchors are reasonable, whether the thickness of roof slab meets the requirements, and the hollow floor shall not be used as far as possible for the earth covered roof in the basement

.

After the formwork is removed, it shall be covered with multi-layer materials with strong water retention for 3-4 days, and then continue to spray water for curing

.

07 manifestations of water seepage around through wall bolts: there is water seepage at the through screws of outer wall and pool wall

.