With the release of the guidance of the general office of the State Council on vigorously developing prefabricated buildings (GBF [2016] No

.

71), prefabricated buildings in China have developed rapidly

.

According to the “general situation of prefabricated building development in 2019” issued by the science and technology and industrialization development center of the Ministry of housing and urban rural development in 2020, 270 million m2 of newly started prefabricated concrete structures will be built in 2019, accounting for 65.4% of newly started prefabricated buildings, and 130 million m2 of steel structures will be built, accounting for 30.4% of newly started prefabricated buildings; 2.42 million m2 of timber structure buildings and 15.12 million m2 of prefabricated buildings with other mixed structures

.

It can be seen that prefabricated concrete structure is the most important structural form of prefabricated buildings in China, which occupies an absolute advantage in all forms of prefabricated structures

.

In order to make peers fully understand and master the latest research and design results of prefabricated concrete structure, this topic specially selects 9 wonderful lectures video or audio and 8 articles for your study and reference, including the latest research and typical engineering cases of node, system, standard and detection technology

.

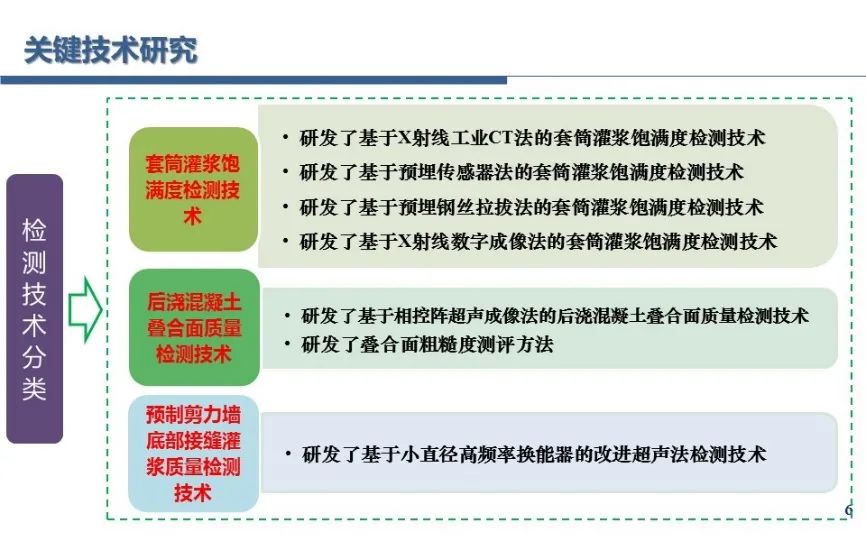

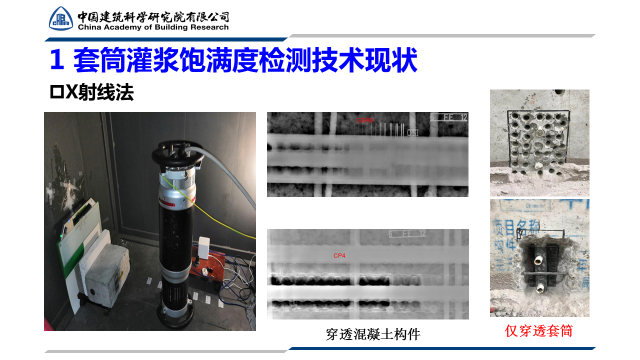

No.1 prefabricated building design and thinking of South China University of Technology Guangzhou International Campus No.2 from prefabrication to integral prefabricated building design – P & T process and experience sharing No.3 modular integrated design of prefabricated concrete building — Taking TongZhou Taihu public rental house as an example No.4 simulation of prestressed dry assembled frame structure Analysis and design method research No.5 experimental research on mechanical performance of dry connection prefabricated shear wall No.6 new node and new system of prefabricated concrete structure No.7 research and standard introduction of multi-storey prefabricated concrete structure No.8 key technology research and standard preparation of prefabricated monolithic concrete building No.9 research on quality inspection technology of steel sleeve grouting connection (see video) No.1 research on mechanical properties of double-sided composite shear wall structure No.2 experimental research on seismic performance of prefabricated concrete frame structure with non load bearing wall No.3 experimental research on repairing grouting defects at different positions of assembled monolithic concrete structure sleeve Research and application of prefabricated structure in Centennial residence( In the first phase project of Guangzhou International Campus of South China University of technology, there are 8 multi-storey concrete frame seismic wall structures using prefabricated technology

.

The prefabricated components used include precast columns, precast main beams, precast secondary beams, precast composite slabs, precast toilet caissons, precast stairs, precast balconies, precast non load bearing enclosure walls and precast concrete beams The assembly rate of internal partition wall, precast beam wall integrated component and local precast shear wall all reach A-level assembly evaluation standard

.

Taking this project as an example, this report describes the design method of prefabricated concrete structure, including split design, structural design, BIM application and Optimization in construction, and introduces the application of new technologies, such as new connection technology of precast concrete components and prefabricated components of recycled block concrete

.

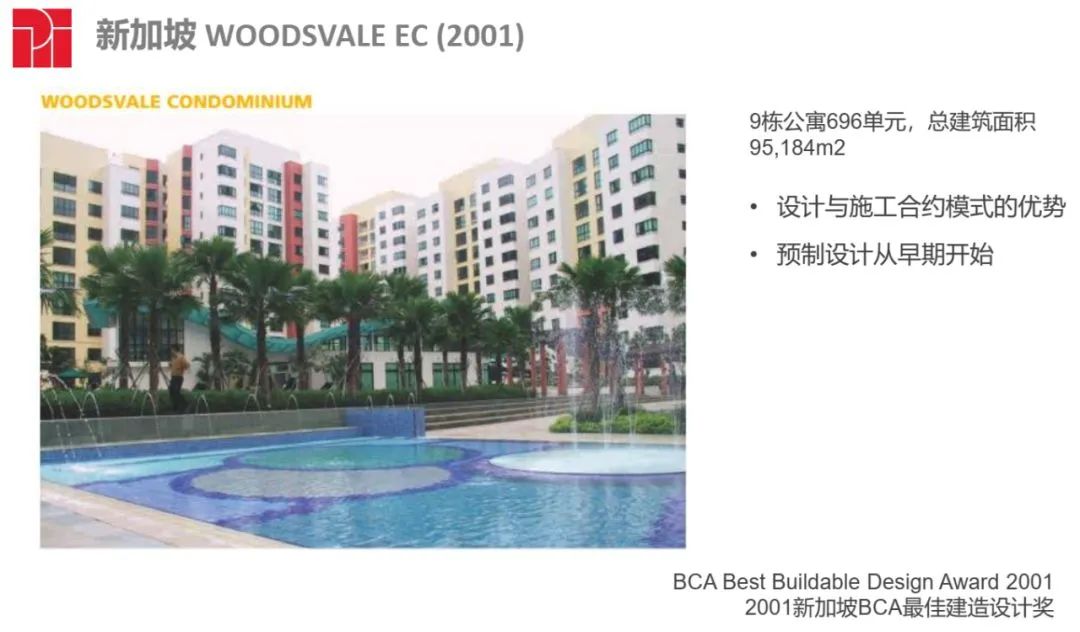

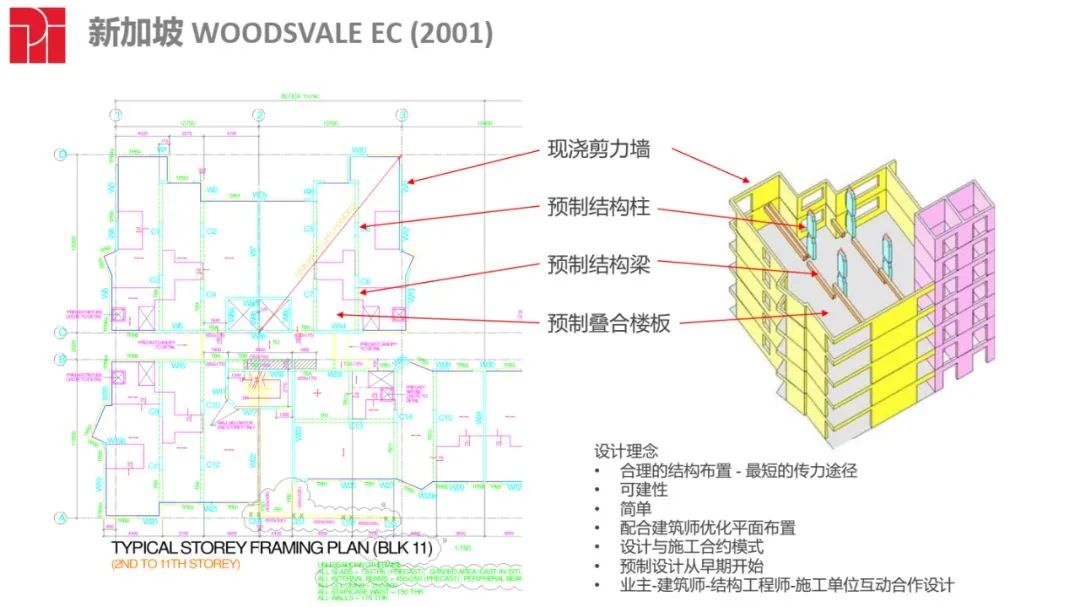

No.2 from prefabrication to integral prefabricated building design – P & T course and experience sharing Liang Huiwen, structural engineer and director of P & T group (click the picture to view the video) main content: Liang Huiwen, structural engineer and director of P & T group, shared the course and experience of P & T from prefabrication to integral prefabricated building design

.

In the 1990s, P & T began the design of prefabricated structure in Singapore, starting from the simple non load bearing retaining wall, and gradually practicing the design of other prefabricated components

.

In the 2000s, the prefabricated load-bearing column was successfully used and connected with grouting steel sleeve

.

The prefabricated load-bearing shear wall, enclosure wall, window sill, balcony, etc

.

were also realized in the project, so as to achieve the construction without scaffolding and the construction of prefabricated components on the construction site

.

In 2010, P & T designed more than 10000 government housing units, all of which use prefabricated structures

.

In 2018, P & T brought Singapore’s experience in the design of prefabricated mass modular buildings to Hong Kong, and developed the design according to the requirements of Hong Kong codes

.

P & T hopes to use it in the construction of the project in the near future

.

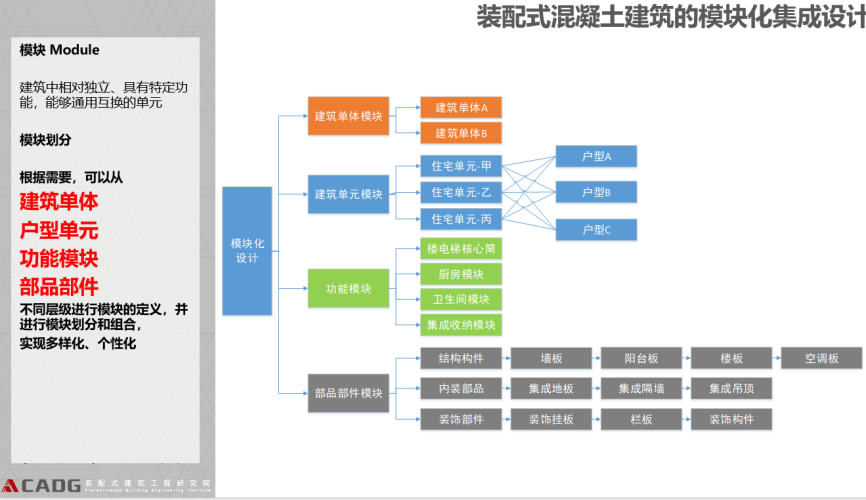

No.3 modular integrated design of prefabricated concrete building — Taking TongZhou Taihu public rental housing as an example, Zhao Dian, President of prefabricated building Engineering Research Institute of China Architectural Design Institute Co., Ltd

.

(click the picture to view the video) the main content of this paper introduces that prefabricated building is a finished building composed of four systems, in order to improve the quality, efficiency, reduce pollution and reduce pollution of prefabricated building To achieve the goal of less waste, it is necessary to carry out the whole professional and whole process integrated design, and the design standardization is the basis of realizing the prefabricated building

.

The report puts forward new ideas and new methods for the standardized design of prefabricated buildings, namely, the standardization of building monomer, unit type, functional module and component parts

.

Taking TongZhou Taihu public rental housing project as an example, it shares the standardized design of building type, unit type, traffic nucleus, kitchen, toilet, component parts and building facade

.

Research on the simulation analysis and design method of No.4 prestressed dry assembled frame structure

.

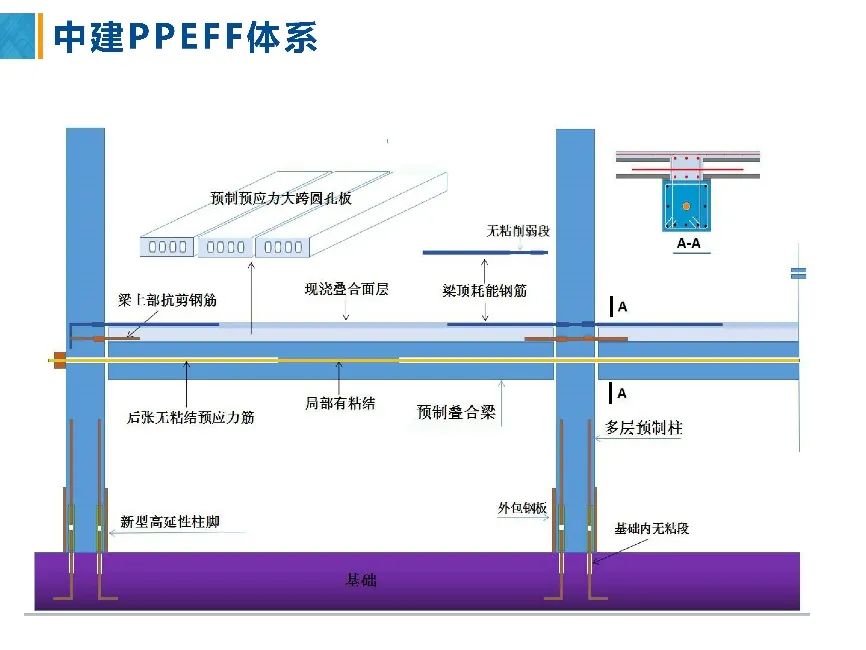

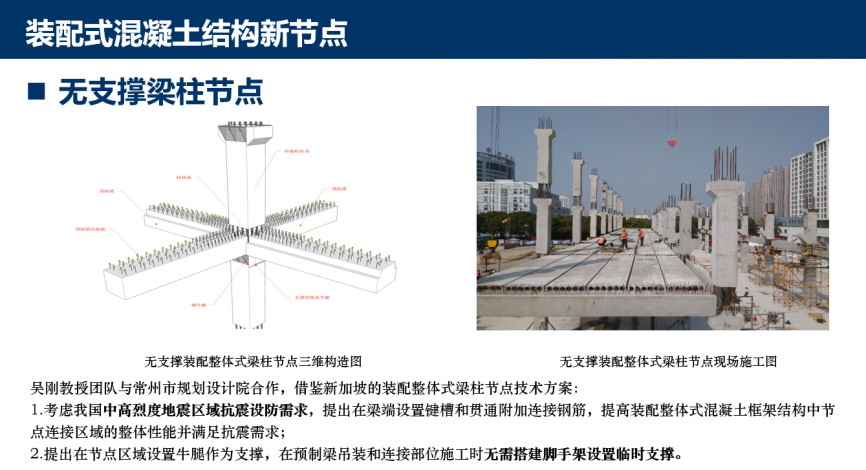

Under the support of the national 13th five year plan and other key R & D projects, Guo Haishan’s team of CSCEC innovated and proposed the prestressed dry rapid assembly frame system (ppeff system) which can be applied in high intensity areas

.

The system structure, working mechanism, material test, joint test, full-scale structure test and engineering demonstration application are systematically introduced

.

This paper focuses on the design method, simulation calculation and performance evaluation method of the ppeff system in China

.

Wei Honghua, vice president of architectural design and Research Institute of South China University of Technology (click the picture to view the video)

.

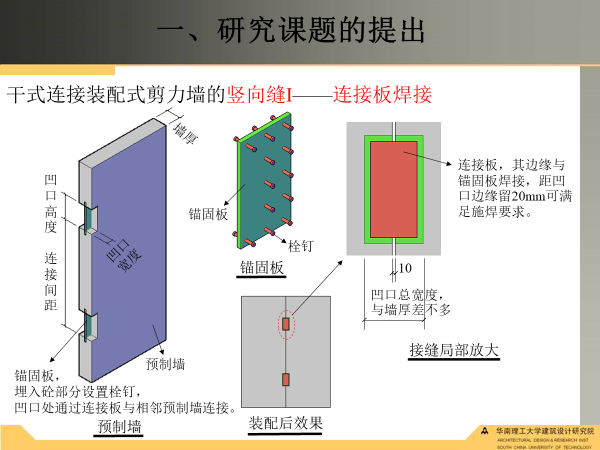

The main content of this paper puts forward the dry connection method of vertical joint and horizontal joint of prefabricated shear wall, that is, welding connection

.

Compared with traditional wet connection, it has the advantages of convenient construction, good connection quality, easy detection and less environmental pollution Dyeing and other advantages

.

Compared with the cast-in-place shear wall, the shear wall with vertical joints has lower stiffness, but the bearing capacity is the same, and the energy dissipation capacity is strong

.

Shear walls with horizontal joints have the same stiffness and bearing capacity as cast-in-place shear walls

.

The joint connection mode of prefabricated shear wall proposed in this report is worthy of popularization and application.

.